Understanding HSS Material Specifications: Which ASTM Should I Specify for HSS?

By Mike Manor, PE, MLSE

Technical Consultant, Steel Tube Institute

August 2022

More than 100 American Society for Testing and Materials (ASTM) Specifications apply to pipe and tubular products. When focusing on specifications relevant to hollow structural sections (HSS), that list can be narrowed down, but how does one know which ASTM applies to which case? It is very easy to get lost in the numbers and not know what each specification is for and why it matters. This article will clarify the intent of many ASTM specifications and how they apply to HSS. Additionally, this article will show the STI resources available to assist design professionals.

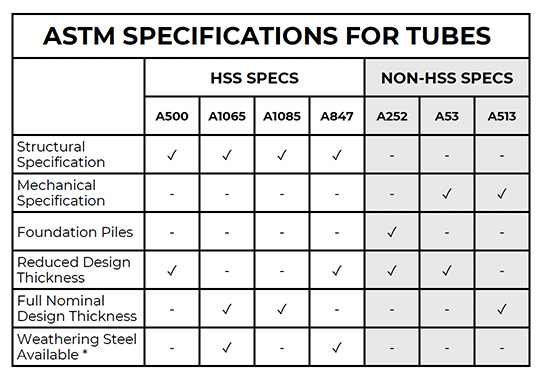

Overview of ASTM Specifications

Table updated: 2/9/24

Useful Steel Tube Institute Resources

STI has many resources available to assist designers with information for availability, geometric properties and design aids for various HSS ASTM specifications. Pertinent resources are listed below with a website link and a brief description for each.

- HSS Producers Capability Tool (free online resource):

- This is a database listing the production capability of the STI member producers. The tool allows designers to search by HSS shape and size to see if it is produced regularly, on demand or not at all. Additionally, contact information for the producers is available when a specific size has been selected.

- ASTM Brochures, Articles and More (free):

- HSS Design Manual Volume 1 (free download):

- This STI manual has tables for round, square and rectangular HSS geometric section properties for several ASTM options.

- HSS Design Manual Volume 2 and Volume 2A:

- These STI manuals have design tables for round, square and rectangular HSS columns and beams to assist designers.

Hollow Structural Section (HSS) ASTM Specifications

A500: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

This specification covers the majority of the HSS used in construction, including round, rectangular and square shapes used for “welded, riveted or bolted construction of bridges and buildings, and for general structural purposes” (ASTM 2021a). The HSS conforming to A500 are cold-formed carbon steel tubes that are made with either a welded or seamless process. When welded, each HSS is made from a flat steel sheet with the opposite two edges welded together by the electric-resistance-welding (ERW) process, which involves simultaneously applying pressure and a strong electric current to melt and forge the steel together.

The 2021 version of the A500 standard has made important revisions affecting the strengths and sizes of the HSS covered by the standard, which are reflected in this description. Grade C is the predominant material available with a yield strength of 50ksi and a tensile strength of 62ksi for all HSS shapes, including round. Most HSS produced domestically is dual-graded for both grades B and C. Thus, STI recommends using grade C as the default for structural notes on a project.

A500 encompasses tubes up to a maximum total perimeter of 88 inches. As an example, this means the maximum square HSS size would be 22 inches x 22 inches. Domestically produced HSS is available in sizes up to 22 inches for square shapes, 34 inches for rectangular shapes, and 28 inches for round shapes with wall thicknesses up to 1-inch nominal. Per A500, the maximum nominal thickness is 1 inch, but due to the thickness tolerance of 10%, AISC 360-16 Section B4.2 requires calculations involving the thickness be multiplied by a factor of 0.93 times the nominal thickness. The maximum corner radius for rectangular and square shapes is 3*t, but the section properties are calculated based on different values depending on the property type to account for averages. As an example, slenderness values for b/t and h/t are based on a corner radius of 1.5*t while the workable flat is based on 2.25*t.

A1085: Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

For nearly all applications, ASTM A500 stands as the preferred choice for Hollow Structural Sections (HSS) up to 88 inches in perimeter. Its longstanding status as the standard reflects its versatility and widespread availability. However, in rare instances where specific needs surpass A500’s capabilities, ASTM A1085 is a viable alternative.

A1085 extends the utility of HSS by accommodating a broader spectrum of applications. A1085 provides additional testing requirements, and improves the efficiency of the HSS members through tighter tolerances and adding property ranges in place of merely having a minimum or maximum value requirement. Locations where this material is used include, but are not limited to, “buildings, bridges, towers, cranes, sign supports and poles, off-shore production and drilling platforms, roll-over protective structures, falling object protective structures, and amusement rides” (ASTM 2015).

It’s crucial to recognize that A1085 isn’t as readily available as A500. Currently, it is produced on demand only, and is not stocked in service centers. Therefore, prior to specifying A1085 for a project, we strongly advise checking the availability of your specified sizes by utilizing STI’s Capability Tool | Steel Tube Institute, and then reaching out to the HSS producers listed.

Like A500, the maximum perimeter of round, square and rectangular tubes is 88 inches, and the maximum thickness is 1 inch. However, the minimum thickness tolerance is only -5% of the nominal thickness. Thus, AISC allows section properties to be calculated with the full nominal thickness. This, along with a minimum mass tolerance of -3.5%, increases the efficiency of the HSS tube. For strength, all tubes have a minimum yield strength of 50ksi, with a maximum of 70ksi leading to a lower seismic overstrength factor (Ry) than A500, thus improving the seismic response characteristics. An additional requirement of a Charpy V-notch test of 25 ft-lb at 40° F meets the AASHTO Temperature Zone 2 requirement for use as primary bridge members.

A1065: Standard Specification for Cold-Formed Electric-Fusin (Arc) Welded High-Strength Low-Alloy Structural Tubing in Shapes, with 50ksi Minimum Yield Point

A1065 covers larger rectangular and square HSS shapes that are outside the scope of A500 however, there is some overlap with A500. Per the STI HSS Capability Tool, the minimum size available is 12-inch x 12-inch. A1065 can also be specified for tapered members. These larger sizes, up to a maximum 200-inch perimeter and 1-inch thickness, are typically used for tall columns or members with long spans or large loading. There are two steel grades available: 50 and 50W. Grade 50W is manufactured with enhanced atmospheric corrosion protection. Both grades have a minimum yield strength of 50ksi; however, the tensile strength for grade 50 is 60ksi compared with 70ksi for grade 50W. Therefore, the supplier cannot substitute one grade for the other without the permission of the purchaser. There is an additional option available in the supplementary requirements for Charpy V-notch testing for use in cyclically loaded structures.

Due to the size of the HSS tubes covered in the A1065 Specification, the tubes are manufactured by first cold-forming two plates into equal-sized C-shapes, which are half of the overall section. These two halves are then welded together with a submerged arc weld (SAW) on both sides to form the final shape. The thickness tolerance for A1065 is much tighter than A500 with a minimum thickness of 0.01 inch less than nominal. Therefore, AISC 360-16 allows cross-sectional properties to be calculated with the full nominal thickness.

A847: Standard Specification for Cold-Formed Welded and Seamless High-Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance

For improved atmospheric corrosion resistance, A847 is the HSS material to turn to. In many applications, A847 steel can be left bare without any paint when properly exposed to the atmosphere. The section properties, maximum sizes and production tolerances are similar to A500. The yield strength is the same as A500 grade C, but the tensile strength requirement is a little higher. However, be aware that AWS does not include A847 as a prequalified base metal. Thus, welding may be a little more difficult but is still possible if the welding procedure is suitable for the steel and intended service.

A501: Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing

To the best of our knowledge, there are no domestic HSS producers that produce HSS per ASTM A501 in a structural application. If you are interested in additional information, please send an inquiry to hssinfo@steeltubeinstitute.org.

Non-structural (Non-HSS) ASTM Specifications

A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

This A53 Specification is for pipe sections that are “intended for mechanical and pressure applications” (ASTM 2020b), which means they must undergo hydrostatic pressure testing. Other places where A53 pipe can be used include ordinary steam, water and air lines. From a structural perspective, they have minimum yield strengths of 30ksi (Grade A) or 35ksi (Grade B), which is considerably lower than HSS specifications such as A500. There is a high tolerance of 12.5% on the thickness, thus AISC requires the nominal thickness be reduced by a factor of 0.93 for design calculations. Based on a combination of the lower strength and additional testing, pipe sections are less efficient and less cost-effective for structures. Therefore, STI recommends that A53 pipes be reserved for nonstructural applications.

A513: Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

As noted in the title, A513 is a specification covering “steel tubing for use as mechanical tubing” (ASTM 2020a). Applications for A513 include various industrial, agricultural and transportation uses. In mechanical tubing applications, dimensional tolerances are critical for pipe fittings, while strength of the member is less important. As a result, A513 does not require any physical requirements such as minimum yield strength, tensile strength or elongation in the main body of the specification but are left as an option under the Supplementary Requirements section that vary based on tube size and must be specified by the purchaser. Depending on the type of tubing, the yield strength is based on a percentage of offset or elongation with a large range of 23ksi to 100ksi. Additionally, the tube wall thicknesses are typically very thin and are nominally called out in wire gauges. When ordering tubing from A513, care must be taken to confirm the correct size/grade is purchased and supplied. Therefore, STI recommends that A513 tubes be reserved for nonstructural applications.

A252: Standard Specification for Welded and Seamless Steel Pipe Piles

The pipe piles covered by A252 can either serve as the permanent load-carrying foundation member or as a form for using cast-in-place concrete piles with composite action. If A252 is presented as a substitution for A500, there are many differences to be aware of prior to deciding if the substitution is acceptable. First, the yield and tensile strengths are lower. Second, the thickness tolerance of 12.5% is larger than A500 allows. Depending on the three grades, yield strengths available are 30ksi, 35ksi or 45ksi with grade 3 being the most common in the current marketplace. Third, A252 has very minimal chemical composition requirements. Thus, care must be taken to ensure weldability of the material. Finally, AISC 360-16 does not include A252 as an approved material. This doesn’t mean that A252 is excluded from use in 360-16, but the engineer must carefully review the material based on the intended use.

Concluding Thoughts

Having so many ASTM options is wonderful so that, as the adage goes, you can use the right tool for the job. This article has discussed many of the structural and nonstructural ASTM options available for HSS but be aware that this is not an all-inclusive list. Each description above gives a rough idea of when each ASTM may be applicable, but further reading of the ASTM standard itself is essential to understand how to know when each applies, the tolerance requirements, and other specific information to be aware of before specifying. For your next project, please visit the HSS Capability Tool on the STI website for assistance on the availability of HSS sizes for several ASTM Specifications.

References

AISC, 2016. “Specification for Structural Steel Buildings,” ANSI/AISC 360-16, and Commentary, American Institute of Steel Construction, Chicago, IL.

AISC, 2017. “Steel Construction Manual, Fifteenth Edition,” American Institute of Steel Construction, Chicago, IL.

ASTM, 2015. “Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS),” ASTM A1085/A1085M-15. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2018. “Standard Specification for Cold-Formed Electric-Fusin (Arc) Welded High-Strength Low-Alloy Structural Tubing in Shapes, with 50ksi Minimum Yield Point,” ASTM A1065/A1065M-18. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2019. “Standard Specification for Welded and Seamless Steel Pipe Piles,” ASTM A252/A252M-19. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2020a. “Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing,” ASTM A513/A513M-20a. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2020b. “Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless,” ASTM A53/A53M-20, American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2021a. “Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes,” ASTM A500/A500M-21. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2021b. “Standard Specification for Cold-Formed Welded and Seamless High-Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance,” ASTM A847/A847M-21. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2021c. “Standard Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing,” ASTM A501/A501M-21. American Society for Testing and Materials International, West Conshohocken, PA.

ASTM, 2021d. “Standard Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing,” ASTM A618/A618M-21. American Society for Testing and Materials International, West Conshohocken, PA.

Olson, K. (April, 2015). “ASTM A1085: An Update to a Classic Material Specification,” Steel Tube Institute.

Olson, K. (January, 2021). “Everything You’ve Always Wanted to Know About HSS, But Were Afraid to Ask,” Modern Steel Construction, pp16-19.

Packer, J. (February, 2017). “Heat Treating HSS,” Steel Tube Institute.

STI, 2021. “HSS Design Manual, Volume 1, Section Properties & Design Information,” Steel Tube Institute.

Related Resources

ASTM Specification: An Interview With Kim Olson

Our latest peer interview with Kim Olson, brings a unique perspective to conversations about ASTMs and best practices that come wh…

HSS CAPABILITY TOOL

Need to locate a producer that can manufacture your HSS sizes? Check out our HSS Capability Tool.

HSS Design Manuals

Tables include round, square and rectangular for HSS section properties and columns and beams.

HSS Resources

Access valuable HSS tools and resources, including live webinars, producer capability tool, spreadsheet design aids, manuals, articles and more.