Keeping Your Cool: How To Get Started With HSS Fire Ratings

By Mike Manor, PE, MLSE

Technical Consultant, Steel Tube Institute

Photo Credit: SOM/Archexist

Every building has fire rating requirements per the applicable building code. Ultimately, there are three ways to deal with fires in buildings: prevention, suppression and resistance. The first two try to stop the fire before it happens or attempt to slow it down, but fires are hard to control and once the fire takes hold, the building needs to be ready to resist as long as possible for the occupants to safely evacuate. That is when fire ratings come into play. The ratings of the materials in the building are a measure of how long they can prevent the spread of the fire or preserve adequate strength to support the structure. To determine the fire resistance of building materials and assemblies, either a specific test must be made per ASTM Specification E119 (also known as UL263) or calculations can be performed based on a general set of tests already available. When steel HSS is chosen to be the structural material, it can be difficult to find information on how to design for fire resistance. This article will give a brief overview of the options available for HSS while pointing to many resources already available that provide much more in-depth information.

Overview Resources:

- STI Manual Volume 1, p. 9-11

- STI Article: Fire Protection of HSS

- STI Webinar: Fire Protection of HSS

- Steelwise: Fire Protection Basics

FIRE RESISTANCE OPTIONS: COVER IT, PAINT IT, FILL IT

Steel is a very strong and versatile building material. When it comes to fires, the good news is that steel is not combustible, but the bad news is that it loses both strength and stiffness at elevated temperatures. At 800° F (427° C), steel retains a minimum of 85% of its yield strength, but by 1,300° F (704° C), the yield strength will only be about 20% of the maximum. This means that bare steel has a short fire rating of only 20 to 30 minutes. Most building code fire rating requirements are typically a minimum of one hour but can be much higher. Thus, the steel needs a little help. The two main categories to increase the fire rating of HSS steel are external insulation and internal insulation. One attribute of steel to understand is that the ratio of mass to the exterior area exposed to the fire affects the rating for both bare steel and insulated steel. A steel shape with a higher mass-to-area ratio will increase in temperature at a slower rate, thus achieving a longer fire rating. For HSS, this ratio is calculated by taking the cross-sectional area of steel divided by the perimeter of the member (A/P). Other steel shapes such as wide flanges use column weight divided by the perimeter (W/D). AISC Design Guide 19 explains this concept further and provides tables for the value of each shape.

External Insulation

There are several options for externally insulating HSS members with the three main options being gypsum insulation boards, spray-applied fire-resistive materials (SFRM) and intumescent coatings (IFRM). Broadly, these three materials work the same by forming an insulating layer between the fire and the steel to slow down the rate of temperature rise in the steel, but how they insulate is different. Gypsum consists of calcium sulfate chemically combined with water, which turns to steam when exposed to fire. This provides a thermal barrier in addition to a physical barrier. The gypsum boards are installed in the field with the number of layers depending on the fire rating required. SFRM is typically a pre-mix of gypsum or Portland cement that has water added on-site, forming a slurry that is pumped and sprayed onto the steel. Depending on the manufacturer and the product used, the density will vary. Thus, the required installation thickness will vary as well. Steel preparation is minimal, and installation is fast but can be messy with the possibility of interfering with the work of other trades. Unfortunately, both options cover up the steel. HSS is typically chosen for aesthetic reasons, which is where intumescent coatings come into play. The coating goes on like paint and can even be colored, but be aware that the intumescent paint comes out with a finish that is bumpy rather than smooth, so that must be considered during design. When exposed to fire, the chemicals in the intumescent coating expand up to approximately 100 times the original thickness while charring along the way to build an insulating barrier. The biggest drawback is that installation can be labor intensive and costly. As an alternative to each of these, there are also prefabricated column options that are covered with proprietary insulating finishes. The benefit is these prefabricated options can be installed quickly by the erector along with the rest of the steel frame.

Internal Insulation

Concrete-filled HSS is another means to increase the fire rating of HSS members while keeping the aesthetic look of the members. The HSS member serves as a permanent form for the concrete so that no additional materials are required. The concrete both serves as a heat sink drawing the heat away from the steel while also releasing moisture in the form of steam, allowing the steel to keep its strength for longer periods of time. Adding rebar or steel fiber reinforcement can further increase the fire rating of the assembly as they help to contain the concrete once it starts to lose its strength. Finally, the concrete also adds redundant structural capacity, which will take the load during a fire event as the steel gradually loses strength. One key item to keep in mind is that ventilation holes must be provided in the HSS to allow the stream from the moisture in the concrete to escape to prevent the HSS column from rupturing due to pressure buildup. According to AISC Design Guide 19, two ½” diameter holes should be installed at both the top and the bottom of an HSS column member. Additionally, the bottom holes should be rotated 90° relative to the top holes. The fire rating of a concrete-filled HSS member can be calculated with the design method and equations shown in the design guide. A second helpful resource is CIDECT Design Guide 4. In section 4.3, there are equations and tables to assist with the rating calculation. Additionally, section 6.2 discusses connections to concrete-filled HSS members in the context of fire rating. For both design guide fire rating methods, there are limitations since the methods are based on testing within the specific range of multiple parameters. The best advantage to filling HSS with concrete is that the fire rating does not depend on the outside finish of the steel. Thus, the finish can be anything that the architectural design requires for the project.

Relevant Resources:

- STI Article: Practical Guidance for Concrete Filled HSS Columns

- Design of Concrete-Filled Hollow Structural Steel Columns for Fire Endurance

- Enhancing the Fire Performance of Concrete-Filled Steel Columns through System-Level Analysis

- Concrete-Filled Hollow Structural Sections (HSS), an Unbeatable Combination

- Intumescent Paint, Fireproofing, and Firestopping

- Spray Applied Fireproofing (SFRM)

- AISC Design Guide 19: Fire Resistance of Structural Steel Framing

- CIDECT Design Guide 4

- Fire Resistance and Sound Control Design Manual – GA-600-2021

OPTIONS TO MEET CODE

The International Building Code Table 601 provides the required fire ratings for building elements listed in hours of fire resistance up to three hours (in certain cases can be even higher). Pay careful attention to the footnotes of this table as there can be reductions and, in some cases, no fire rating is required for steel. For example, a steel building with the entire roof structure at least 20 feet above the floor does not require a fire rating for the structural members. So how are these ratings achieved in practice? There are three options: tested ratings, prescriptive ratings and a performance-based design.

Tested Ratings

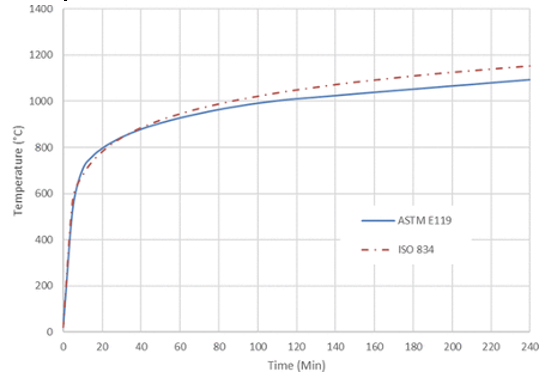

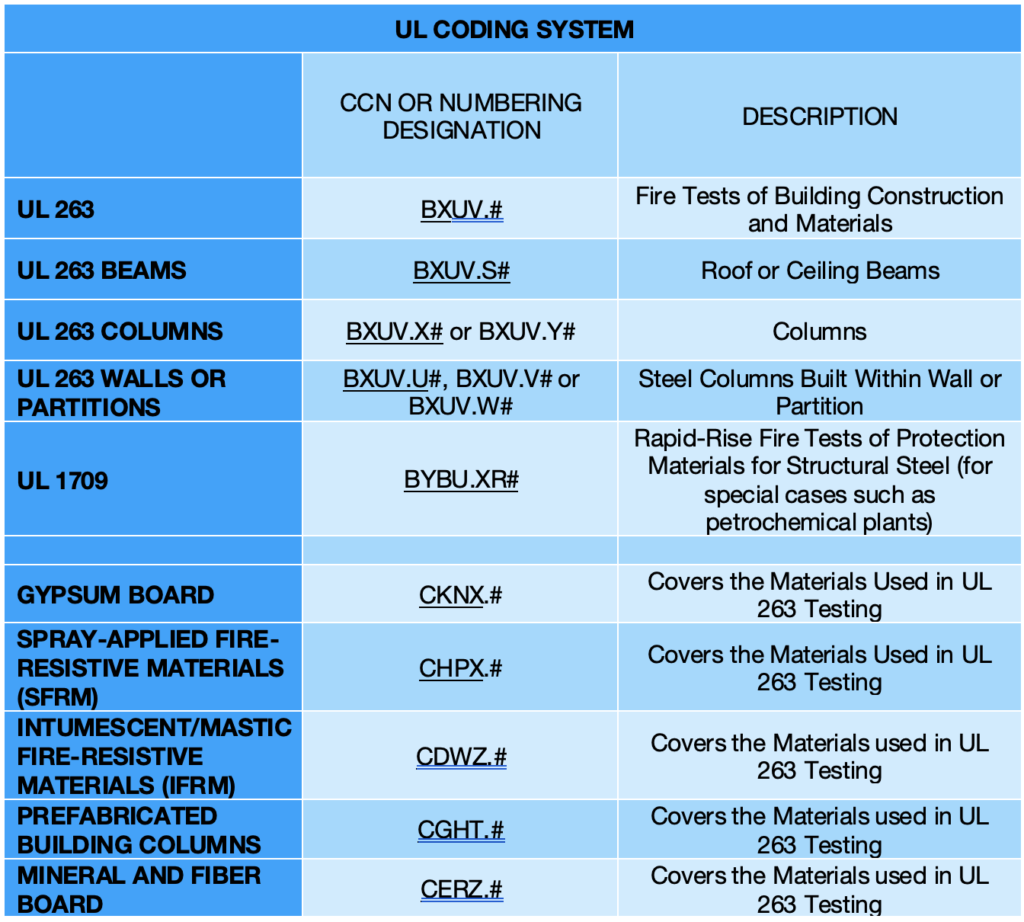

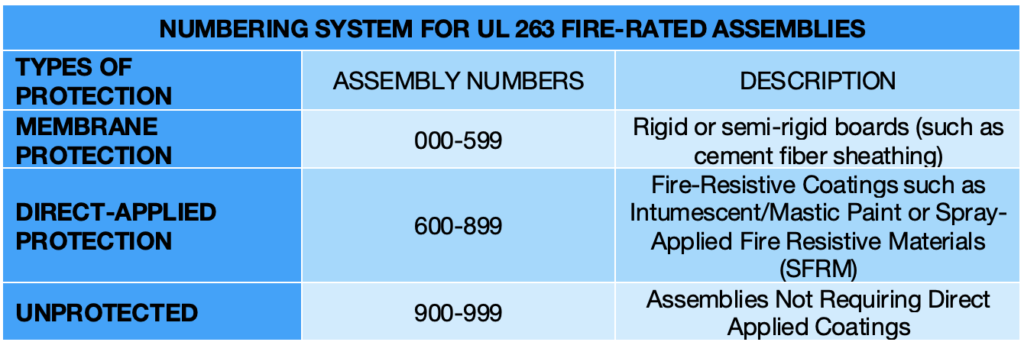

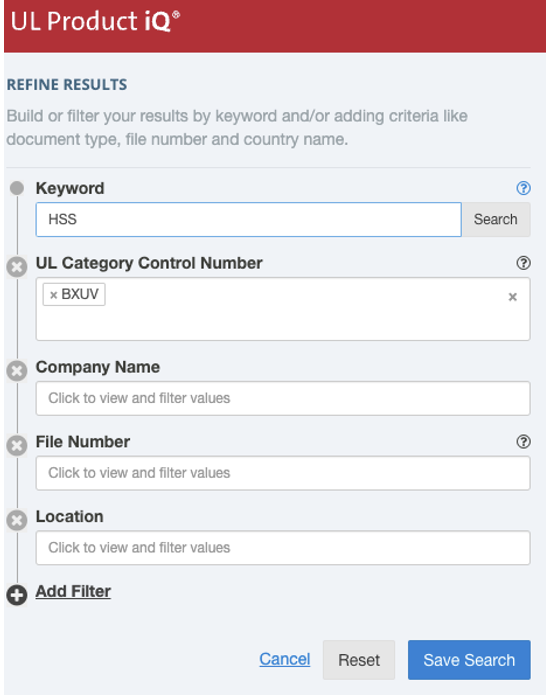

Underwriter Laboratories (UL) is an accredited developer of standards in the United States and Canada, which also works with similar organizations around the world. Among the standards they provide is ANSI UL263 (also known as ASTM E119), which provides a means to test the fire resistance of construction products/assemblies in a gas furnace based on a fire temperature-time curve to simulate a fire event. Figure 2 shows a graph of the testing temperature that continually rises over time, reaching 1,000° F (538° C) at five minutes and continuing to 2,000° F (1,093° C) at four hours. Once an assembly has been tested, UL creates a certification that reports the fire rating in hours and places it in its database at UL Product iQ® (https://productiq.ulprospector.com/). This is a free service to use but requires creating an account to log in for access to all reports. All fire-rated assemblies that have been tested under UL263 for use in the United States have a category control number (CCN) of BXUV and in Canada are BXUVC or BXUV7. Going one step further, all materials in the assembly are covered by a separate CCN that the materials must adhere to. See Tables 1 and 2 for a partial list of fire-resistant materials. To help speed up the UL search process, links to the database are included in the table. The “Guide Info” documents are very useful documents that explain the requirements behind that particular CCN such as BXUV.GuideInfo.

For tips on searching specifically for rated assemblies with HSS members, first limit the UL CCN to BXUV, then search for keywords such as HSS, tube or tubular (see figure 3). For example, if you are looking for a fire-rated assembly for an HSS column, look in the list of document names for either BXUV.X### or BXUV.Y###. For fire-rated assemblies that depend on restraint conditions, see UL Specification 263 table C1.1 for a list of restraint conditions for common construction situations.

Prescriptive Ratings

Prescriptive fire ratings are any that involve calculation as noted in applicable codes or design references. Between the International Building Code (IBC) chapter 7 and the AISC Design Guide 19, there are several options for quickly calculating the fire resistance of steel HSS members. These are all based on limited laboratory testing with generalized equations that determine allowable fire ratings. Unfortunately, due to the prescriptive nature of these equations, the fire ratings tend to be conservative and only have a limited range of parameters for which they are valid. There are four calculation options, which include covering the HSS column with gypsum wallboard, spraying fire-resistant materials onto the HSS, encasing the HSS in concrete or masonry, and filling the HSS with concrete. IBC Chapter 7 has many pre-tabulated tables for prescriptive methods. When the building design uses HSS for aesthetic reasons, filling the HSS with concrete becomes the only option for prescriptive design, which is a great option but the drawback is the maximum two-hour fire rating. The calculation must be performed as the IBC does not include any tables for concrete-filled HSS (see previous section on internal insulation). Some other limitations are a maximum column effective length of 13 feet, a minimum outside dimension of 5-1/2 inches, and a maximum outside dimension of 12 inches for rectangular HSS and 16 inches for round HSS. For additional information and calculation examples, see the STI Fire Protection Webinar listed in the resources section and AISC Design Guide 19.

Relevant Resources:

- Fire Resistance and Sound Control Design Manual – GA-600-2021

- UL 263 Specification

- Straightforward Specification

- AISC Design Guide 19: Fire Resistance of Structural Steel Framing

- CIDECT Design Guide 4

- STI Webinar: Fire Protection of HSS

Performance-Based Design

Photo Credit: Tata Steel and SOM/Bruce Damonte

The prescriptive fire resistance design requirements for structural members in the IBC is a one-size-fits-all approach. However, for large or complex buildings, there are specialty fire protection engineers with in-depth knowledge of both the behavior of fires in buildings and the intent of the fire resistance sections of the building code. The Society of Fire Protection Engineers recommends a holistic approach for the entire building involving portions of the design from the architect, structural engineer, mechanical engineer and electrical engineer. The final design would include an agreed-upon set of safety goals by all parties based on a probabilistic design approach. Thus, the design for fire suppression systems, smoke control systems and structural member fire resistance is based on realistic fire scenarios and realistic loading levels. Per IBC section 104.11, alternative design methods can be submitted to the building official for approval provided the design method is “satisfactory and complies with the intent of the provisions of this code.” This is where performance-based design comes into play to establish fire protection design criteria for the building design that is at least equivalent to the code.

For the structural portion of the design, there are computer programs that run simulations of real-world fire events. As noted earlier, the UL263/ASTEM E119 test fire continually increases in temperature until there is a failure due to either thermal criteria or structural criteria. In a real-world fire, the temperature does increase until all combustible material has been consumed. The temperature levels out and then begins to drop. The performance-based design method and the associate software take all of this and more into account. The programs are first calibrated to match the lab testing behind the prescriptive fire rating requirements. Then the program can be ran for special situations or for standard situations but with HSS members that are outside of the previous testing parameters. Since this design approach is more realistic rather than conservative, it can result in lower construction costs for standard situations or result in solutions better suited to unique situations. The structural engineer of record should identify which structural members are critical to the fire resistance. If one of those column members fails, determine the load path and redistribution to prevent progressive collapse. Then collaborate with the fire protection engineer to determine the final design.

To help the engineer of record understand how to start toward a performance-based design, there are several resources available. Starting in ASCE 7-16 (also included in 7-22), appendix E was added to describe a list of design requirements that must be considered. Additional information is available in PS-02-07 from the Society of Fire Protection Engineers (SFPE). Once this list of requirements has been established, a fire protection engineer can be brought onto the design team and use ASCE MOP 138-2018 (MOP = manual of practice), which gives specific direction on how to meet the requirements. Of course, the sooner a fire protection engineer can be involved in the design, the better the overall building design will be to help keep construction costs to a minimum.

Relevant Resources:

- How To Use Performance-Based Design for Fire Protection Systems

- PS-02-07 The Role of the Fire Protection Engineer in the Construction Design Process

- The SFPE Guide to Performance-Based Fire Safety Design

- ASCE 7-22 Appendix E

- ASCE MOP 138-2018

CONCLUDING THOUGHTS

Design for fire events in buildings has come a long way in the past couple decades, but remember that insulation for HSS steel members is key whether internal or external. Many more options have become available to design for fire resistance. In some buildings, the prescriptive methods make perfect sense for a quick design, but it is important to be aware of the limitations early on. It is also good to be aware that some design guides have not been updated recently, thus do not include the most up-to-date research. Larger projects or unique projects may benefit from the expertise a specialty fire protection engineer can offer. Either way, we are all in this together to provide safety for the general public.

REFERENCES

Architectural Record, (2017, November). “Concrete-Filled hollow Structural Sections (HSS), and Unbeatable Combination.”

Archtoolbox, (2021, May). “Intumescent Paint, Fireproofing, and Firestopping.” Archtoolbox.

Archtoolbox, (2021, May). “Spray Applied Fireproofing (SFRM).” Archtoolbox.

ASCE, (2018). “ASCE MOP 138-2018 Structural Fire Engineering,” Amerßican Society of Civil Engineers, Reston, VA.

ASCE, (2022). “ASCE/SEI 7-22 Minimum Design Loads and Associated Criteria for Building and Other Structures,” American Society of Civil Engineers, Reston, VA.

Carter, C.J., Alfawakhiri, F., Varma, A.H., Ioannides, S.A., (2017, June). “Straightforward Specification,” AISC Modern Steel Construction.

Fike, R.S., Kodur, V.K.R., (2013, March). “Enhancing the Fire Performance of Concrete-Filled Steel Columns through System-Level Analysis,” International Journal of High-Rise Buildings, Vol. 2, No 1, 11-21.

Golinski, B. (2017). “Fire Protection of HSS,” Webinar, Steel tube Institute.

Golinski, B. (2017, July). “Fire Protection of HSS,” Steel Tube Institute.

Gypsum Association, (2021). “Fire Resistance and Sound Control Desgin Manual – GA-600-2021 23rd Edition.” Gypsum Association.

Kodur, V.K.R., Mackinnon, D.H., (2000, First Quarter). Design of Concrete-Filled Hollow Structural Steel Columns for Fire endurance,” Engineering Journal, 13-24.

Moriarty, N.A., (2017, May). “How To Use Performance-Based Design for Fire Protection Systems,” Consulting-Specifying Engineer.

Olson, K. (2015, September). “Practical Guidance for Concrete Filled HSS Columns,” Steel Tube Institute.

Ruddy, J.L., Mario, J.P., Loannides, S.A. and Alfawakhiri, F.A. (2003). “Hollow Structural Section Connections,” Steel Design Guide No. 19, American Institute of Steel Construction, Chicago, IL.

Society of Fire Protection Engineers, (2007, March). “Position Statement P-02-07: The Role of the Fire Protection Engineer in the Construction Design Process,” Society of Fire Protection Engineers.

Society of Fire Protection Engineers, (2015). “The SFPE Guide to Performance-Based Fire Safety Design,” Society of Fire Protection Engineers.

Stockmann, M. (2009, September). “Steelwise: Fire Protection Basics,” Modern Steel Construction.

STI, 2021. “HSS Design Manual, Volume 1, Section Properties & Design Information,” Steel Tube Institute.

Twilt, R., Hass, R. Klingsch, M., Dutta, D. 1994. “Design Guide for Structural Hollow Section Columns Exposed to Fire,” CIDECT Design Guide No. 4, CIDECT, Geneva, Switzerland.

Underwriters Laboratories. (2011). “ANSI/UL 263 Ed. 14-2011 Standard for Fire Tests of Building Construction and Materials,” Underwriters Laboratories

October 2022

How Fire Resistance and Progressive Collapse Shape the Steel Industry and Beyond

Dr. Spencer Quiel, associate professor of engineering at Lehigh University, discusses research in fire resistance, blast and progr…

Fire Protection of HSS

Learn how internal and external insulation can increase fire resistance and details existing research on this topic.

Webinars On Demand: Fire Protection of HSS

Explore how HSS can be fireproofed both externally and internally in our Webinars On Demand.