Welding of Hollow Structural Sections

by Jeffrey A. Packer

Bahen/Tanenbaum Professor of Civil Engineering, University of Toronto, Ontario, Canada

Matthew R. McFadden

Research Assistant, Department of Civil Engineering, University of Toronto, Ontario, Canada

March/April 2012

The welding of Hollow Structural Sections (HSS) does have some unique features. Unlike open sections, where welding is typically possible from both sides of an element, welding of HSS is only possible from one side, thus requiring larger weld sizes. Second, the main HSS member face to which a branch is welded is generally much more flexible than its wide‐flange counterpart, as the two webs of the main member (which act as stiffeners) are at the outside of the connection rather than in the middle, as would be the case with a W‐shape web. This increased flexibility of the connecting face tends to cause an uneven load distribution in the welded joint.

An important first step is to have selected the members in an HSS connection astutely. For truss‐type connections, the branch width‐to‐chord width ratio (β) should be relatively high (say 0.7 to 0.8), but still preferably enable the branch to sit on the “flat” of the main member if it is a square/rectangular HSS. (An exception to this recommendation are connections in Vierendeel frames, where matched‐width HSS [β ≈ 1.0] are typically necessary in order to achieve full moment capacity). In addition, the branch thickness‐to‐chord thickness ratio (τ) should be relatively low; less than unity, with a value of 0.5 being a good target. These conditions will generate a truss‐type connection with a high static strength (and a high fatigue resistance too). As member selection is intimately tied to connection capacity, and most HSS connections are required to be unreinforced, it is clear that checking the connection capacity is the responsibility of the structural engineer.

Three basic types of welds account for practically all structural weld joints, including those between HSS: complete‐joint‐penetration (CJP) groove welds, partial‐joint‐penetration (PJP) groove welds, and fillet welds.

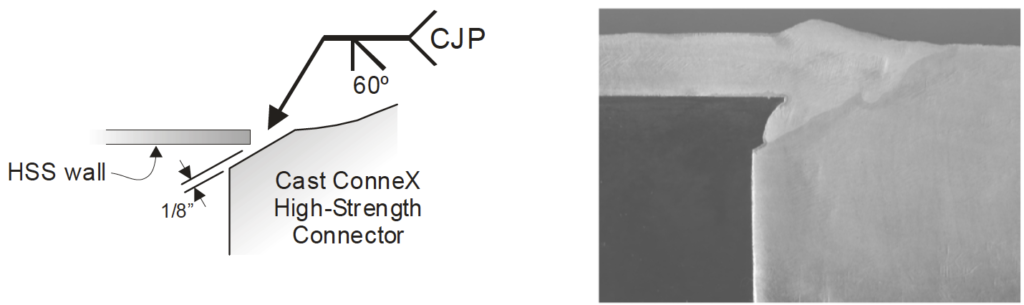

Complete‐Joint‐Penetration groove welds (from one side and without backing) are extremely expensive, require specially qualified welders, and should almost never be specified for HSS connections. One exception that comes to mind is for a round HSS welded to a proprietary steel special‐purpose casting – the High‐Strength Connector by Cast Connex Corp., used with diagonal HSS braces in seismic load‐resisting braced frames (shown in Fig. 1). In this case the tapered nose of the casting inserted into the HSS or pipe essentially serves as backing.

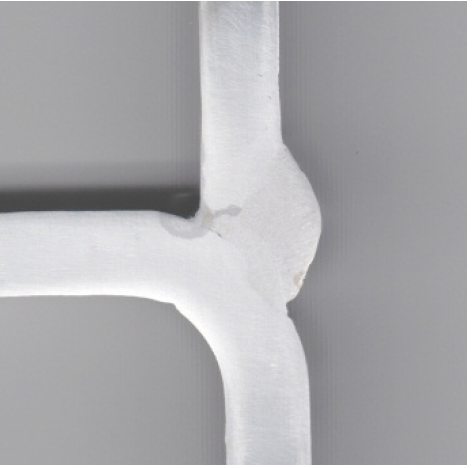

Partial‐Joint‐Penetration groove welds are an option for HSS connections, especially if fillet weld sizes become large (leg sizes over about ½ in.) and the branch member is reasonably thick. Prequalified joint details for PJP welds to HSS, particularly for the longitudinal welds in “matched box” connections as in Fig. 2, are given in AWS D1.1 (2010).

Fillet welds, being the least expensive and easiest weld type, are the preferred and most common weld type for HSS connections. The design of fillet welds in structural steel buildings in the US is governed by AISC 360‐10 Table J2.5 and is based on the limit state of shear failure of the weld using a matching (or under‐matching) filler metal. For a simple 90° T‐joint the LRFD resistance of a single weld is given by:

ФRn= ФFnwAwe = (0.75)(0.60FEXX)(D/√2)(weld length), where D = weld leg size.

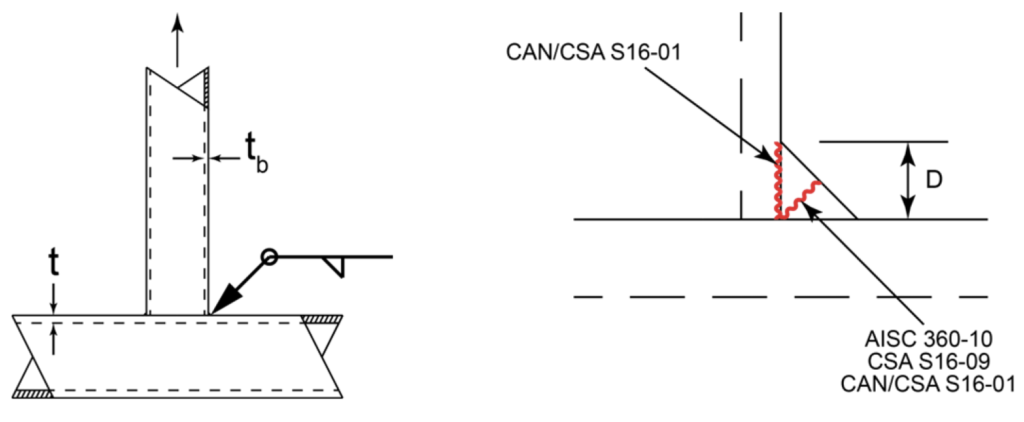

The design of fillet welds in Canada is governed by CSA S16‐09 Clause 13.13.2.2, and although different coefficients are used, an identical resistance is obtained. Both AISC and CSA allow an enhancement to the nominal strength of the weld metal (of 1.0 + 0.50 sin1.5θ) for welds loaded at an angle of θ degrees to the weld longitudinal axis, plus include some further provisions for weld groups. AISC 360‐10, however, limits the sinθ enhancement factor to only weld groups where all elements are in a line or are parallel (also referred to as linear weld groups). Thus, the apparent inapplicability of this factor to HSS T‐, Y‐ and K‐connections is pointed out in AISC Design Guide No. 24 (Packer et al., 2010). The CSA standard, on the other hand, does not rule out the applicability of the sinθ factor for HSS connections, leading to a much greater resistance for a fillet weld group in a HSS connection and hence much smaller weld sizes (see Table 1). The prior edition, CAN/CSA S16‐01, included a check for shearing of the base metal at the edge of a fillet weld along the fusion face (see Fig. 3), which frequently governed and thus resulted in generally larger weld sizes at that time.

Weld Design for HSS‐to‐HSS connections can be performed to either of the following two design philosophies (Packer et al., 2010; Packer and Sun, 2011):

- The weld may be proportioned so that it develops the yield strength of the connected branch wall at all locations around the branch, or

- The weld may be proportioned to resist the applied branch forces, with adjustments for uneven stress distributions along the length of the weld.

Examining Method No. 1, this will represent an upper limit on the weld size – and hence a conservative design procedure. For example, consider the simple 90° HSS‐to‐HSS T‐connection under branch axial tension load in Fig. 3, with sections manufactured to ASTM A500 Grade C and fillet welded with E70 electrodes. In this case all welds are oriented transversely (at 90°) to the applied load, form a non‐linear weld group, and one can consider that the HSS branch wall yield resistance, per unit length, is given by:

(Ф = 0.9)Fytb = 45tb kips/in, where tb is the branch wall thickness.

It is interesting to consider the fillet weld effective throat size that is required to develop this branch wall resistance, according to various specifications/codes (see Table 1). Clearly there is quite a disparity.

| Specification or Code | Weld Effective Throat |

| ANSI/AISC 360‐10 Table J2.5 | 1.43tb |

| AWS D1.1/D1.1M: 2010 Clause 2.25.1.3 and Fig. 3.2 | 1.07tb |

| CSA S16‐09 Clause 13.13.2.2 | 0.95tb |

| CAN/CSA S16‐01 Clause 13.13.2.2 | 1.14tb |

| CEN (2005) or IIW (2009) | 1.10tb |

Method No. 2, essentially a “fit for purpose” approach, involves taking weld effective lengths into account because HSS welded joints typically have highly varying load distributions around their perimeter. For joints with relatively low branch forces, the use of weld effective lengths may lead to smaller weld sizes and result in a more economical weld design. The same effective weld size should still be maintained all around the attached branch, with the entire branch perimeter welded. (An exception to the latter may apply to the “hidden weld” in HSS‐to‐HSS overlapped connections). Some HSS weld effective lengths were introduced into AWS D1.1 in the 1990s, based on prior experimental research, then AISC 360 adopted these in 2005 and further expanded the coverage in Section K4 of AISC 360‐10. IIW (2009) specifically acknowledges the effective length concept for weld design but, like all other steel design specifications/codes except AISC 360 and AWS D1.1, does not prescribe any effective lengths.

To validate or further improve the HSS weld effective rules added to Section K4 of AISC 360‐10, an AISC‐sponsored experimental research project is currently being performed by the authors on weld‐critical HSS‐to‐HSS T‐connections, under branch in‐plane bending, and on weld‐critical HSS‐to‐HSS overlapped K‐connections within complete trusses. The heightened interest in welding of HSS is also reflected in the recent formation of an AWS Tubular Task Group, at the instigation of AASHTO, primarily to address tubular bridge construction.

References

AISC. 2010. “Specification for Structural Steel Buildings”, ANSI/AISC 360‐10, American Institute of Steel Construction, Chicago, IL.

AWS. 2010. “Structural Welding Code – Steel”, AWS D1.1/D1.1M:2010, 22nd. edition, American Welding Society, Miami, FL.

CEN. 2005. “Eurocode 3: Design of Steel Structures – Part1‐8: Design of Joints”, EN1993‐1‐8:2005(E), European Committee for Standardization, Brussels, Belgium.

CSA. 2001. “Limit States Design of Steel Structures”, CAN/CSA S16‐01, Canadian Standards Association, Toronto, ON.

CSA. 2009. “Design of Steel Structures”, CSA S16‐09, Canadian Standards Association, Toronto, ON.

IIW. 2009. “Static Design Procedure for Welded Hollow Section Joints – Recommendations”, 3rd. edition, IIW Doc. XV‐1329‐09, International Institute of Welding, Paris, France.

Packer, J., Sherman, D. and Lecce, M. 2010. “Hollow Structural Section Connections”, Steel Design Guide No. 24, American Institute of Steel Construction, Chicago, IL.

Packer, J.A. and Sun, M. 2011. “Fillet Weld Design for Rectangular HSS Connections”, Engineering Journal, American Institute of Steel Construction, 1st. quarter, pp. 31 – 48.

Related Resources

- Welding in HSS Corners

- Weld Effective Lengths for Round HSS Connections

- Design of Fillet Welds to Rectangular HSS

- CJP HSS Welds: Be Informed Before You Specify

- Variety of Experience Lends Itself to Mentorship: A Conversation With Duane Miller

- Webinar On Demand: Know Your HSS Welds

- Webinars On Demand: HSS Weld Seams

HSS Resources

Access valuable HSS tools and resources, including live webinars, producer capability tool, spreadsheet design aids, manuals, articles and more.