mechanical tubing

Overview

Mechanical tubing, producing according to ASTM A513, performs functions that are broad and far reaching making it the most versatile of all tubing specifications. Mechanical tubing is produced from flat steel progressively rolled into a finished size and shape. An electric resistance weld creates the seam. The outside weld bead is removed producing a finished product with a smooth surface. This tubing is classified as “as-welded”. Sink drawn and drawn over mandrel tubing is then drawn through a die to achieve other attributes.

Types of Products

As-Welded

As-welded mechanical tube is mechanical tubing that does not undergo additional processing at the mill.

Drawn Over Mandrel

Drawn Over Mandrel (DOM) starts with an as-welded tube. The tube is then drawn through one or more dies and over mandrels to achie…

Sink Drawn

Sink drawn tube starts with an as-welded steel tube which is drawn or pulled through a die that reduces the outside and inside dia…

Benefits of Mechanical Tubing

Precision

Precise dimensions and tight corners mean customers receive the exact uniformity they are looking for.

Less Processing

The close dimensional tolerances of mechanical tubing allow its use with minimal downstream processing.

Variety of Shapes

Mechanical tubing is produced in round, rectangular, oval, trapezoidal, tear-drop and other specialty shapes in a variety of surface finishes.

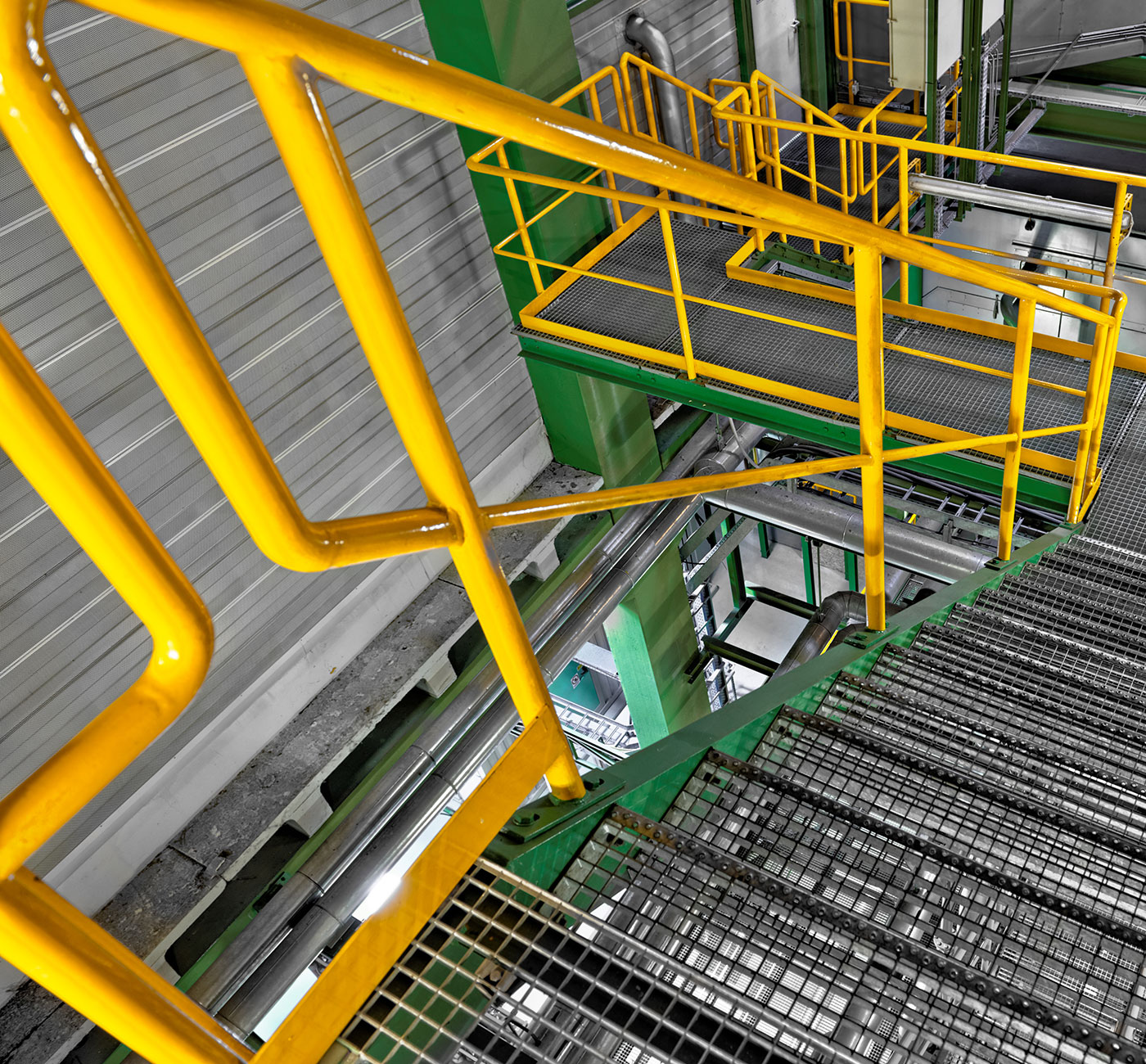

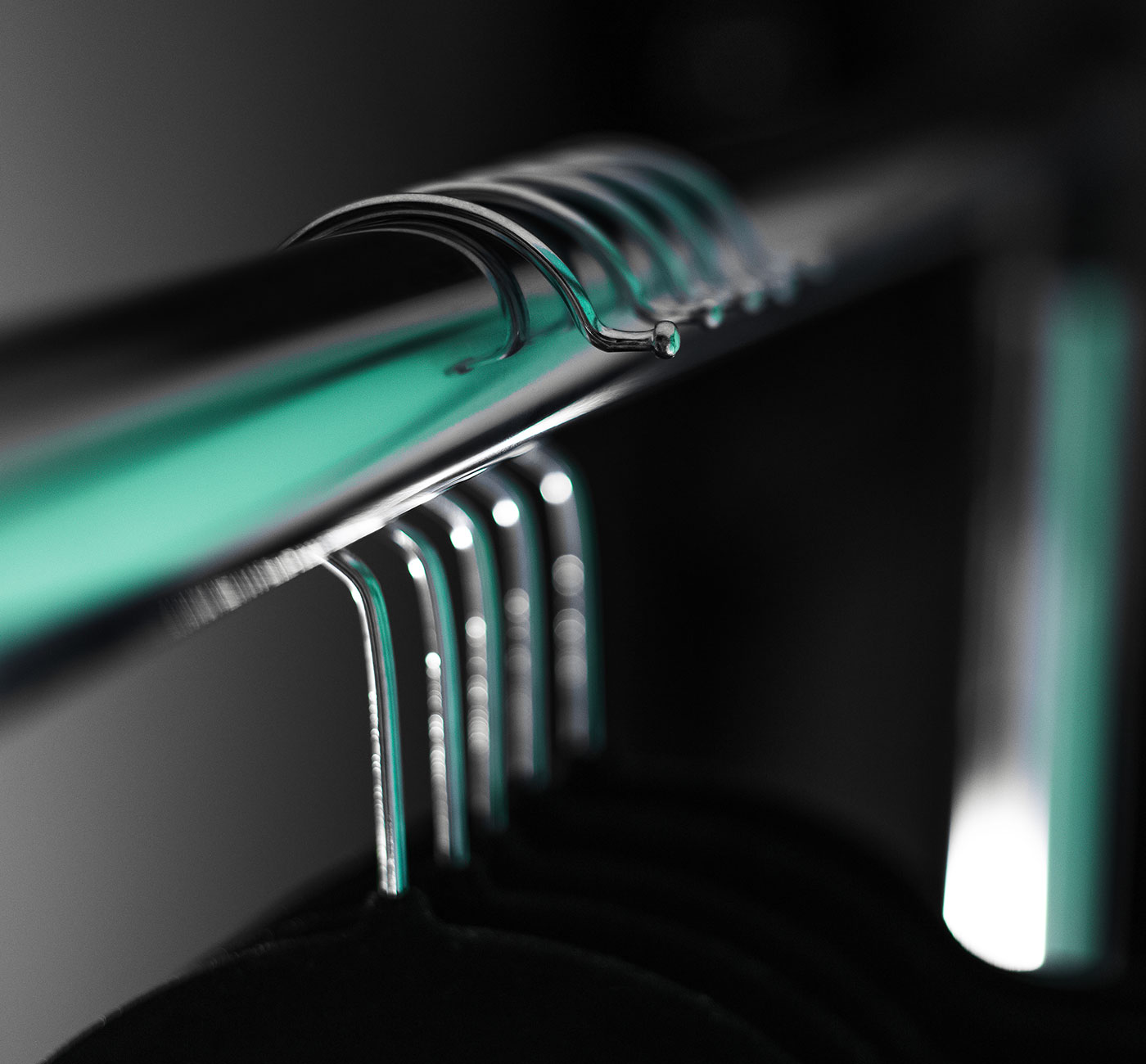

Applications

Applications from bicycle frames and lawn mower handles to high strength industrial applications demonstrate the versatility of mechanical tubing. As the end uses are endless, so are the assortment of sizes, shapes and gauges to which this product can be rolled. Here are just some of the different applications:

Mechanical Tubing Producers

The membership of the Steel Tube Institute represents the majority of North America’s producers.