Wide-Flange Beam to HSS Column Moment Connections

By Jason Ericksen, SE

FORSE Consulting, Technical Advisor to Steel Tube Institute

October 2014

Hollow Structural Sections (HSS) are efficient members to use in a variety of applications, including moment frames. When the beams and columns are HSS members, moment connections can be designed using the provisions in the American Institute of Steel Construction (AISC) Specification for Structural Steel Buildings Chapter K. The tables in Chapter K cover various connection configurations and provide the limit states with the applicable strength equations. When the beams are wide-flange sections and the columns are HSS, there are multiple options for moment connections and these will be discussed in this article.

It is important to remember that connecting to an HSS column is different than the considerations of connecting to the flanges of a wide-flange column. The moments in the wide-flange beams are resolved into concentrated forces at the beam flanges that must be transferred into the column. The main difference between an HSS and wide-flange column is how the forces from the beam flanges are transferred into the column webs to be resisted as shear. In a wide-flange column, the web (and thus the stiffness) is located at the center of the column flange. In an HSS column, the forces applied to the column face must be transferred to the side-walls, which act as the webs. Due to the fact that HSS walls are generally thinner and must transfer the forces to the sidewalls, the thickness of the HSS column wall becomes a critical consideration for the strength and stiffness of a moment connection between an HSS column and a wide-flange beam.

Given these considerations, the common connection types discussed in this article and the recommendations that accompany them are generally aimed at having the concentrated forces from the beam flanges applied as close to the sidewalls of the HSS column as practical. Two general recommendations can be made for all connection configurations; design the column to eliminate the need for reinforcement at the connection and keep the ratio between the column width and the beam flange width close to one.

When possible, the connection configuration and forces applied to the HSS columns should be considered when selecting the column size. Thicker walls and/or narrower column face dimension can strengthen and stiffen the column wall and remove the need for costly stiffeners or column reinforcing. Put more simply, it is typically more economical to have heavier columns than to have reinforced connections. This is true of connections with wide-flange columns as well. There are requirements for applying concentrated forces to the flanges that may lead to stiffener or doubler plates at the moment connections (when the column web or flanges are not thick enough). AISC recommends using heavier column sections to avoid costly connection reinforcement.

The second recommendation is to keep the column width and beam flange width at optimal ratio. Narrow beam flanges (as compared to the width of the column face) concentrate the force to the central portion of the HSS wall, making the thickness of the wall more critical.

Five of the most common connection types are discussed in this article, but there are several other viable configurations discussed in the resources sited. This article is focused on low-seismic applications, but there are connections suitable for high-seismic applications.

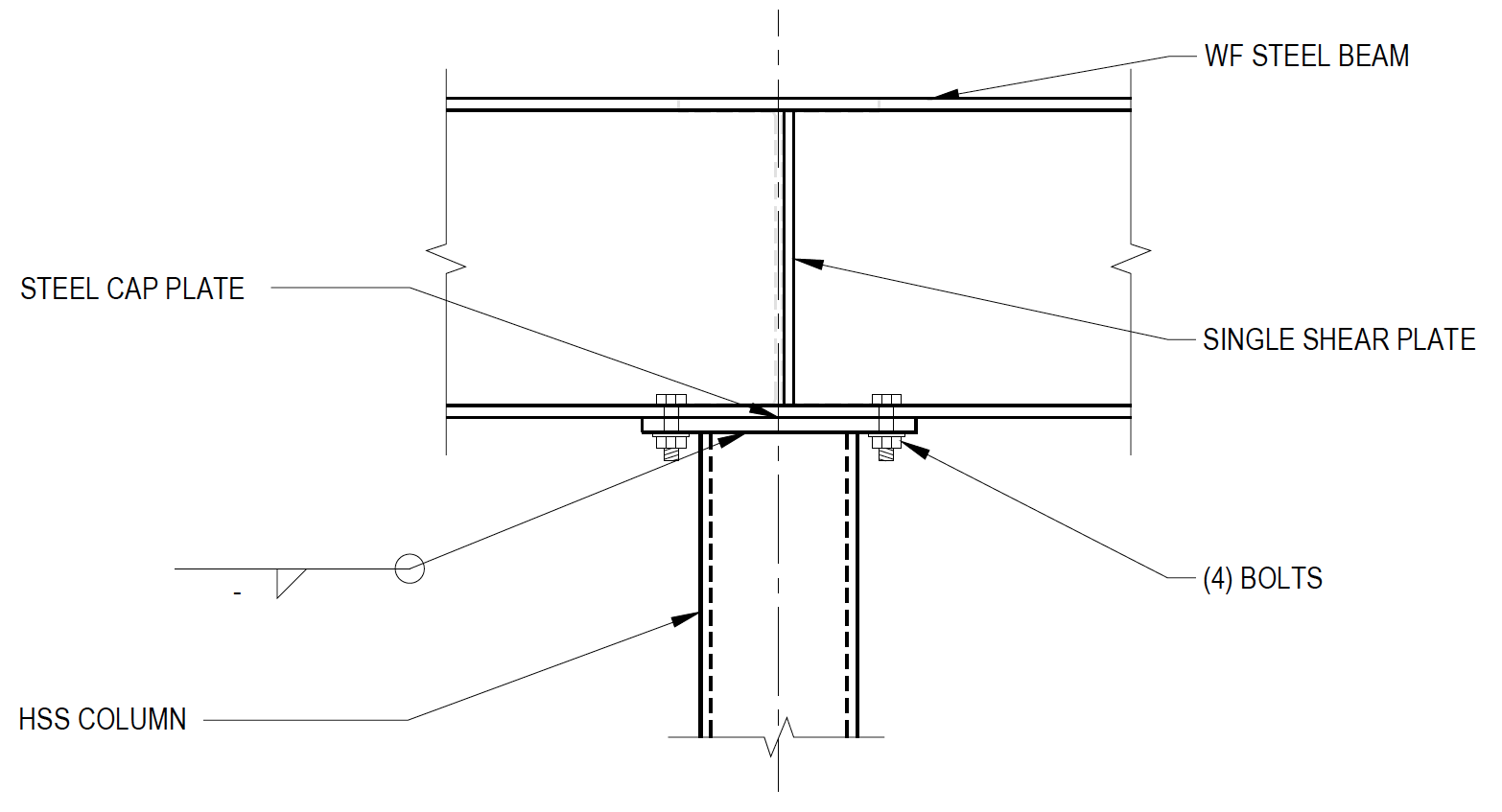

Continuous Beam

In this connection type, the beam remains continuous through the connection, removing the need to transfer the moments from the beam into the column. This is a very economical connection for single-story buildings. The connection of the beam to the top of the column does not need to transfer moment and can be done with a simple cap plate bolted to the beam flanges. It is vital to provide out-of-plane bracing to the top of the column. If this is not provided the effective buckling length of the column may be significantly larger than the story height.

This connection can also be used for multiple stories. In this configuration, the beam is continuous, but the column is “spliced”. The beam web can be stiffened with plates or with split HSS sections to match the column section to provide a load path for the column axial loads.

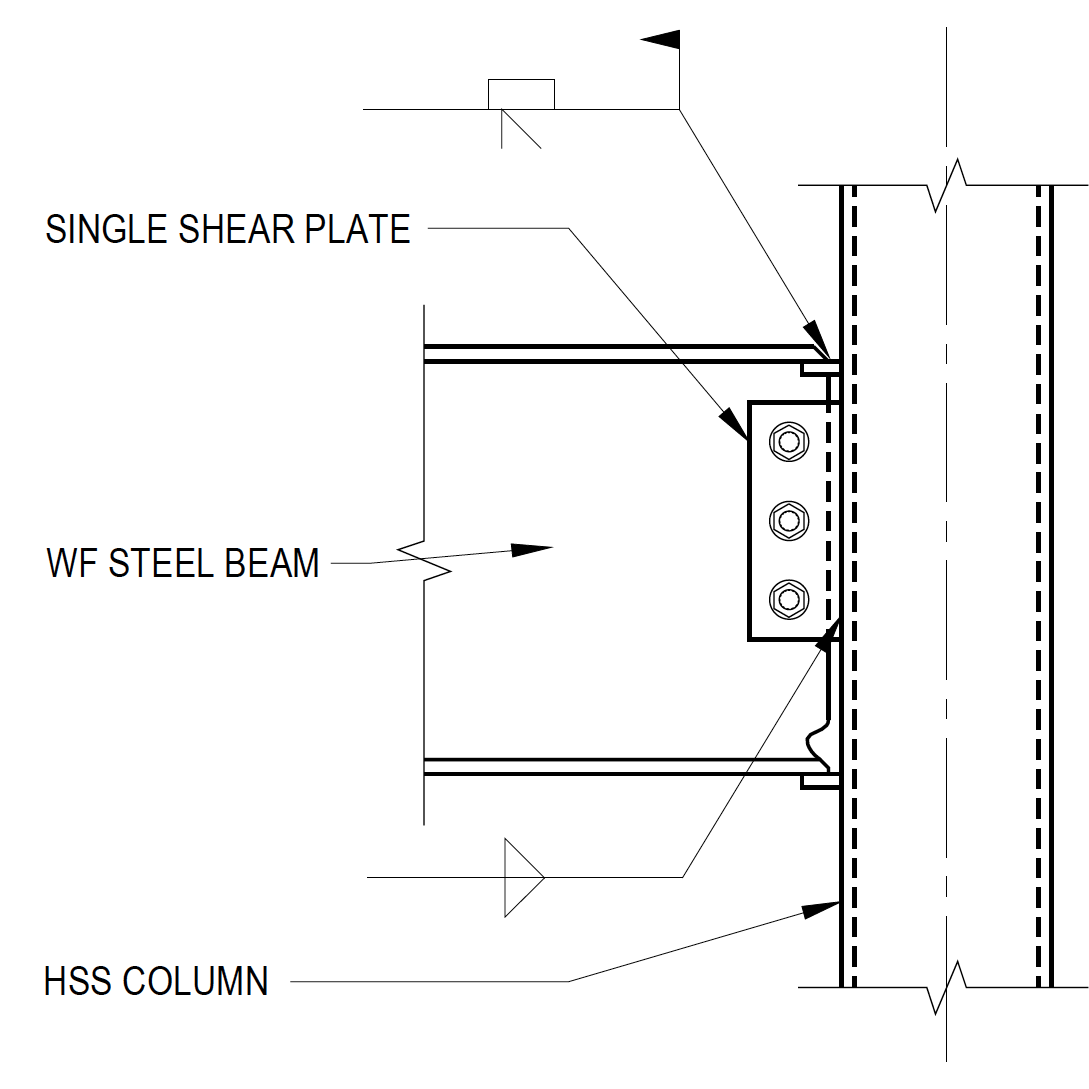

Directly Welded

This is a fairly common connection and is able to transfer significant moments from the beams into the column. However, if the required moment approaches the full flexural strength of the beam, one of the other connection configurations discussed may be required. At high moments, the flexibility of the HSS wall can limit the moment that can be transferred. For best results, use a thicker column wall and consider keeping the ratio of the workable flat dimension to the beam flange width close to one. The HSS column is evaluated using the provisions in Chapter K of the AISC Specification for a transverse plate with an axial load. There are limits states that apply to the beam flange, the HSS column face, and the column sidewalls.

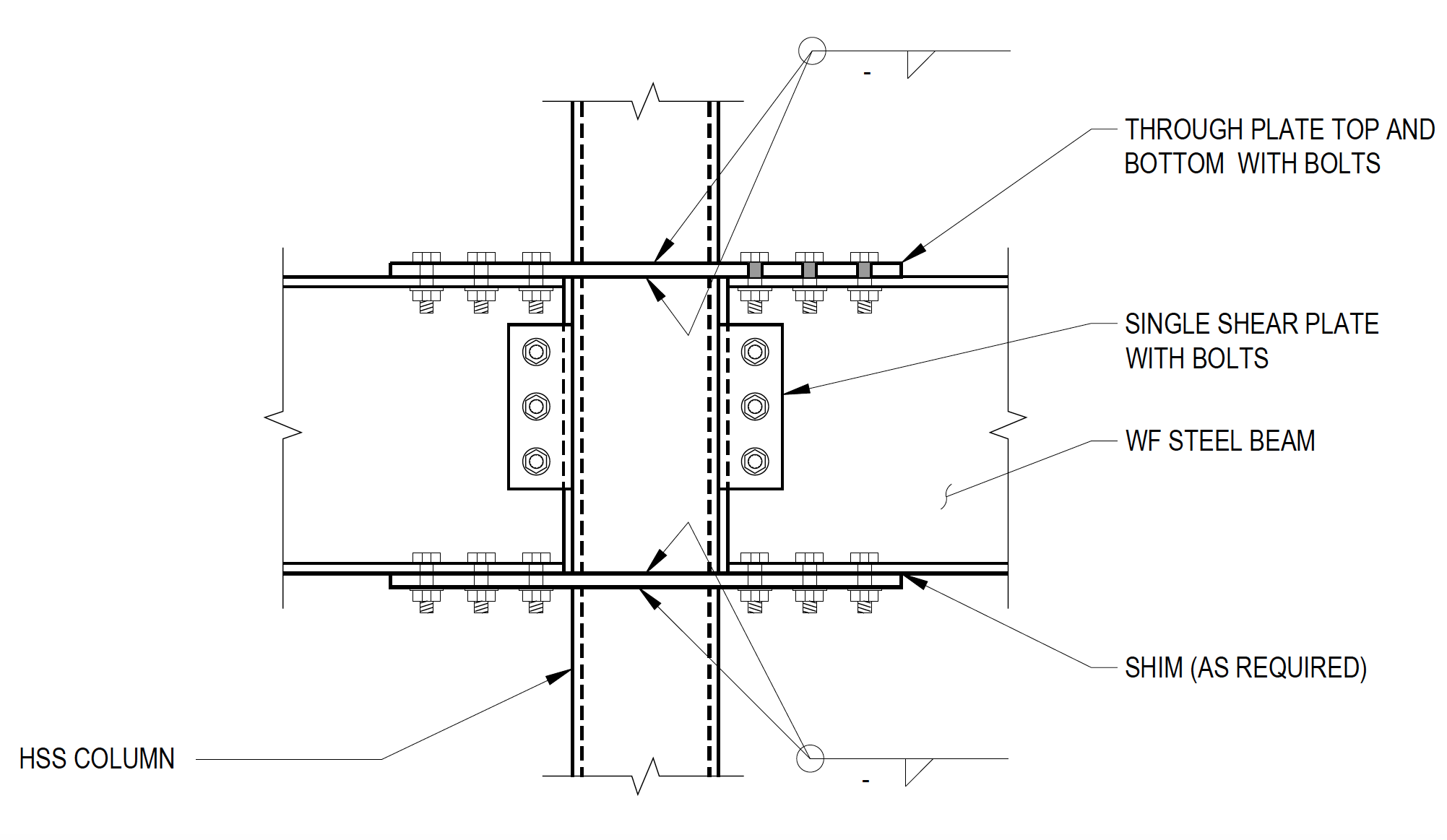

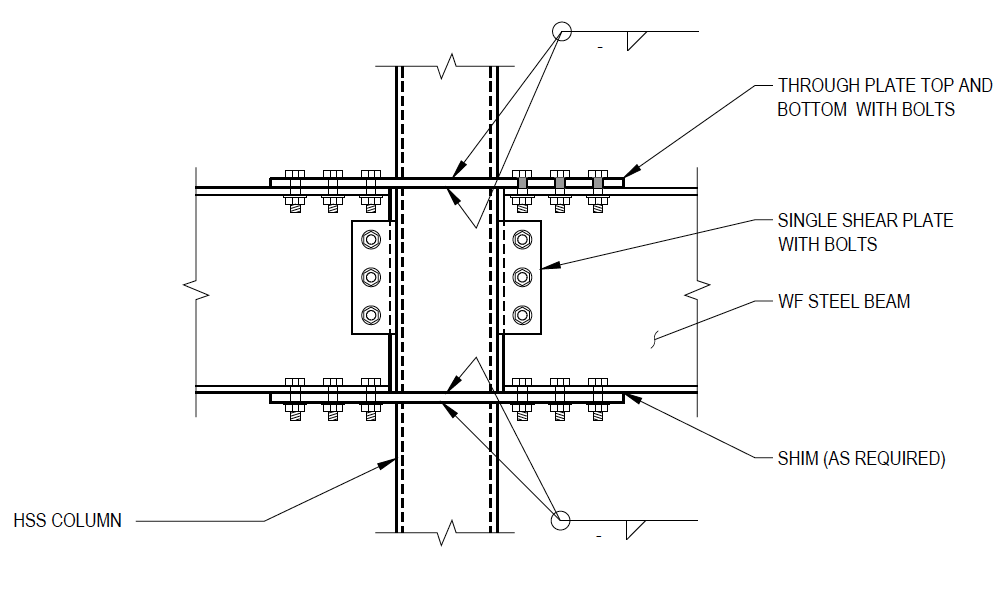

Through-Plate

The through-plate connection is more difficult and costly to erect than the directly welded connection but can provide greater moment strength. In this connection, the column is cut in two places to allow through plates at the top and bottom flange of the beam to pass through the column. This connection allows the moments to transfer from beam to beam using the flange plates and does not require the forces to be transferred through the column. When designing the connection, it is important to consider how the beams will be erected. Since there is a top and bottom plate, the beam will have to be put in place from the side if the plates are attached in the shop. In this configuration, a single shear plate is required to allow erection. Another option is to shop weld the bottom flange plate and field weld the top flange plate so that the beam can be placed from above. There is more freedom in the shear connection when this is done.

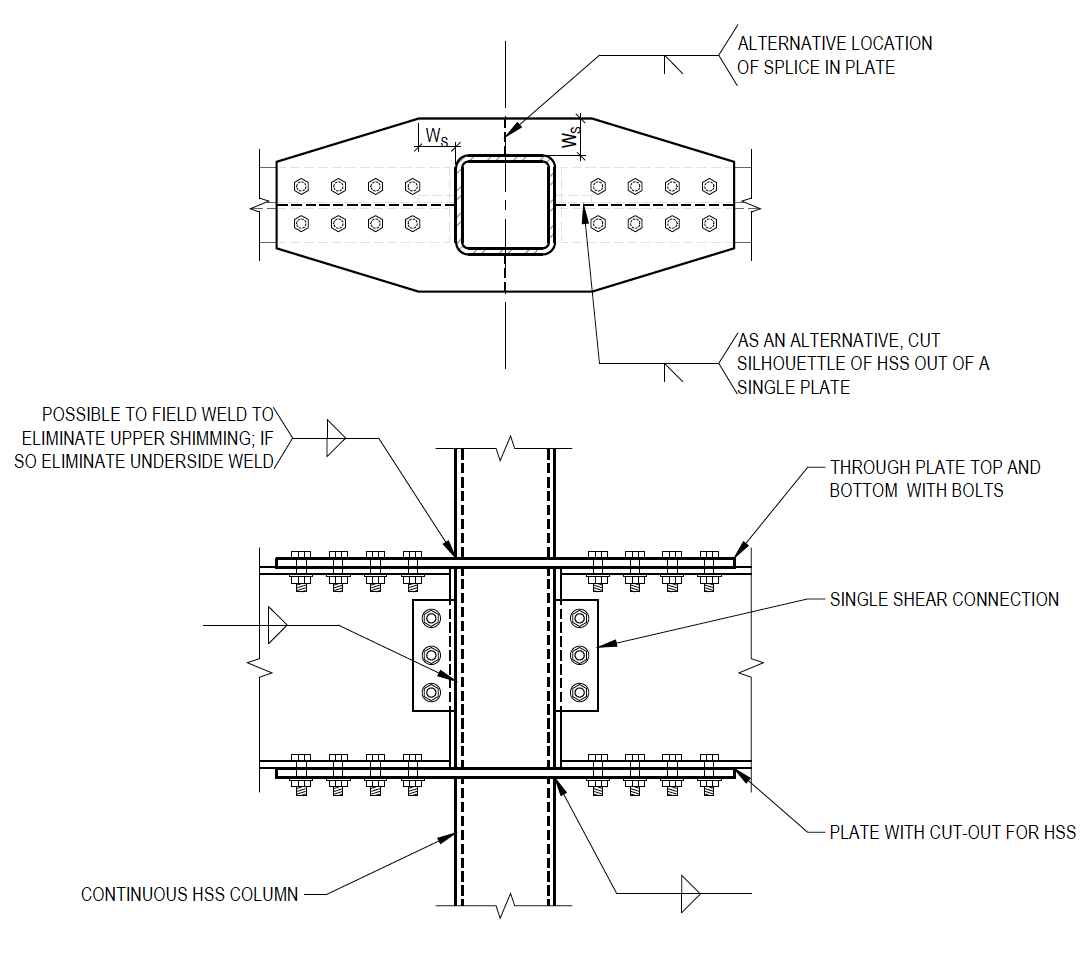

Exterior Diaphragm Plate

The exterior diaphragm plate connection (also known as a cut-out plate) is similar to the through-plate connection in that it uses flange plates to transfer the moments. However, in the exterior diaphragm plate connection the column is continuous and the top and bottom plates are cut around the column. This makes the fabrication of the connection a bit easier because the column does not need to be cut. However, the connection plates are wider than the column, which may cause architectural interference.

The same erection considerations as the through-plate apply to the exterior diaphragm plate when the plates are attached to the column in the shop. The exterior diaphragm plate connection can be effectively used for one-sided connection as it allows the beam flange forces to be transferred directly to the sidewalls of the HSS column.

Interior Diaphragm Plate

Plates are shop welded inside the tube to stiffen the HSS column walls in an interior diaphragm plate connection. The beam flange forces are transferred in a direct manner through column wall to the interior plate and through the connection. The welding of the interior plates can be somewhat difficult and limits the use of this connection in the United States. This is a very popular connection in Japan where highly automated shop welding makes these welds more practical. In this connection, the column is only cut once and the beam is directly welded to the column. Because the reinforcement is within the column itself, this connection has architectural advantages while still providing the ability to resist large beam moments.

High Seismic Applications

The connection types already discussed can be used for Steel Ordinary Moment Frames if you meet the requirements of the AISC Seismic Provisions (AISC 358). For Special and Intermediate Moment Frames, the moment connections must be tested or prequalified. The most common path is to use one of the connections from the AISC Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications (AISC 358). This document contains a proprietary connection from ConXtech® that uses HSS columns and wide-flange beams. In addition, SidePlate® provides connections using HSS columns that have ICC ES reports for both IMF and SMF systems. These reports are often sufficient for prequalifying proprietary connections.

Research is ongoing for high seismic connections with HSS columns. Extensive research is being done in Japan and Europe where the use of HSS columns is the norm. Tests are showing that connections to HSS column perform well when detailed appropriately. Research in Japan on the through-plate and internal diaphragm connections (equivalent to the protocol required for AISC 358 prequalification) has been completed. However, similar testing must be done within the US in order to have the connections included in AISC 358.

Resources

There are resources available for the design of moment connections between wide-flange beams and HSS columns. Part 12 of the AISC Steel Construction Manual contains a discussion of moment connections to HSS columns and the AISC Design Guide #24 contains discussions of specific connections types, the limit states to consider, and include examples. The textbook Hollow Structural Section Connection and Trusses by J.A. Packer and J.E. Henderson includes details and examples of the five connections discussed and several more options available.

Additional Related Resources

- Beam to HSS Column Axial and Moment Connection Examples

- Deep Dive into HSS Shear and Moment Connection Examples

- Beam-to-HSS Column Moment Connections Using Laser-Cut Columns

- Square and Rectangular HSS-to-HSS Moment Connections

- HSS Beam to HSS Column Connections

HSS Resources

Access valuable HSS tools and resources, including live webinars, producer capability tool, spreadsheet design aids, manuals, articles and more.