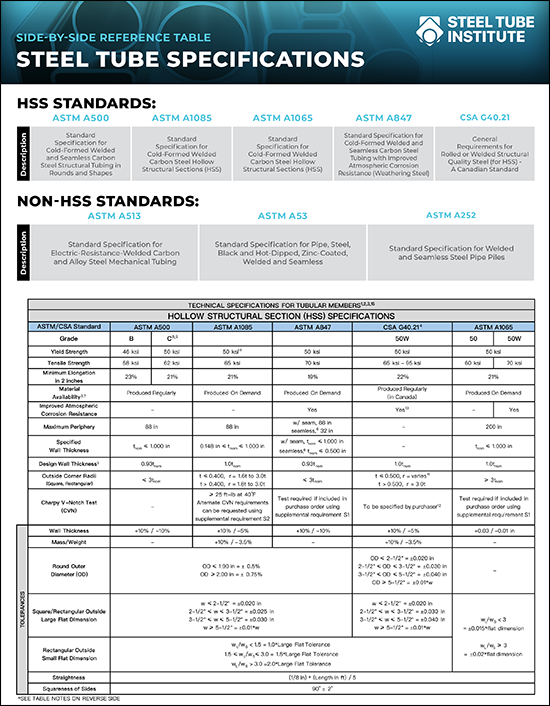

Steel Tube Specifications: Side-by-Side Reference Table

Steel Tube ASTM Specifications: Side-by-Side Reference Table

March, 2025

Understanding the specifications for Hollow Structural Sections (HSS) is essential for selecting the appropriate standard for your project. This table provides a straightforward comparison of key ASTM/CSA standards for steel tubes, highlighting the differences between various HSS standards and non-HSS tube standards to help users identify the right specification for their needs.

HSS Standards

- ASTM A500 – Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

- ASTM A1085 – Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

- ASTM A1065 – Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

- ASTM A847 – Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Tubing with Improved Atmospheric Corrosion Resistance (Weathering Steel)

- CSA G40.21 – General Requirements for Rolled or Welded Structural Quality Steel (for HSS) – A Canadian Standard

Non-HSS Standards

- ASTM A513 – Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

- ASTM A53 – Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- ASTM A252 – Standard Specification for Welded and Seamless Steel Pipe Piles

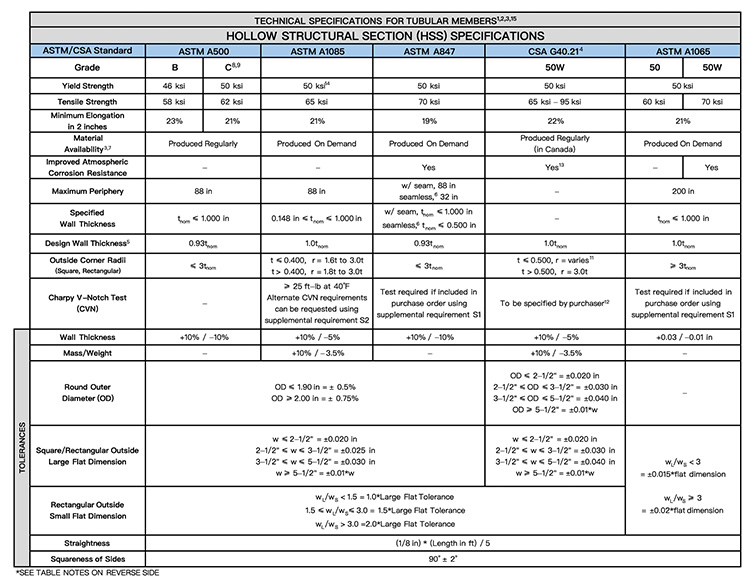

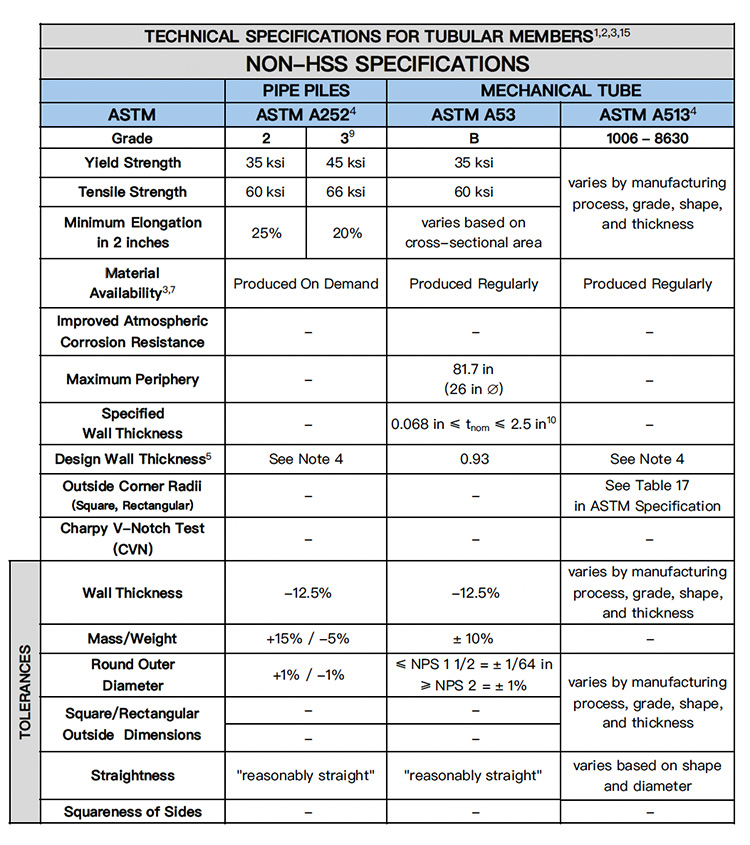

This table offers a clear comparison of dimensional properties, material strengths, and tolerances, making it easier to determine the appropriate specification for a given application.

Table Notes

- A dash (“–”) indicates that the specification does not have a requirement for this item.

- OD = Outer Diameter

tnom = specified nominal thickness

w = width of large flat

wL/wS = ratio of large flat width to small flat width - For availability of specific sizes of ASTM A500, ASTM A1085, ASTM A1065 and ASTM A513, see: STI HSS Capability Tool

- Material not included in the scope of AISC 360-22 Specification Table A3.1. Refer to Sections A3.1a and A3.1b, or applicable design standard, for design guidance.

- Per AISC 360-22, Section B4.2, a factor is required to be multiplied by the nominal HSS thickness to determine the design thickness for engineering calculations.

- Seamless only applies to round sections

- Produced Regularly: Indicates standard sizes are typically available Produced on Demand: Indicates tube is made to order based on customer needs

- Preferred grade for structural applications

- Most common grade

- Thickness options vary based on Nominal Pipe Size (NPS) designation and ASTM A53 Table X2.2

- Corner radius varies between 0.128 in and 1.5 in based on thickness

- HSS with CVN tests can be ordered using the grade designation WT (weldable notch-tough steel) and indicating a Category (which indicates a test energy and temperature)

- Improved atmospheric corrosion resistance for CSA G40.21 is available by using the below designations. For example, 50AT in lieu of 50W.

A = Atmospheric corrosion-resistant weldable steel

AT = Atmospheric corrosion-resistant weldable notch-tough steel - Test specimen yield strength cannot exceed 70 ksi

References

- STI Article: Understanding HSS Material Specifications: Which ASTM Should I Specify for HSS?

- STI HSS Design Manual Volume 1: Section Properties & Design Information includes tables listing section properties for HSS square, rectangular, and round sections.

- STI Tolerance Guide and Video summarizes tolerances allowed by ASTM A500 HSS.