EPD: Achieving Green Goals With HSS

By Cathleen Jacinto, PE, SE, Technical Consultant, Steel Tube Institute

Joseph Anderson, Executive Director, Steel Tube Institute

When we think of a steel mill, we might imagine a picture of dark skies, rusty exposed steel and billowing smokestacks. There is a long-held preconceived notion that steel mills are “dirty.” Not so! During the last 30 years, the steel industry has made major strides forward with modern technology and significantly reduced greenhouse gas emissions. In one sector of today’s steel mill, we will instead find cleaner and more controlled electric arc or induction furnaces, charged with increased amounts of scrap steel, less raw material and overall smaller production footprints. Steel mills are now surrounded by green landscapes, a sign of sustainability. Structural steel produced in the United States through this modern process contains an industry average recycled content of 93 percent. The most recycled material by weight in the world is steel, and it can be repeatedly recycled without the loss of metallurgical and engineering properties. For these reasons, steel is a premier green construction material and should be considered alongside any other material when designing for sustainability.

Recently, a strong legislative push to lower embodied carbon in buildings resulted in the Buy Clean California Act, which was enacted into law in 2017 and limits the amount of embodied carbon allowed in California’s public projects. Effective July 1, 2022, projects entering into contracts with State of California agencies must meet specified embodied carbon thresholds. This is the first-ever legislation to target carbon emissions for select construction materials. Only steel, which includes hot-rolled sections, HSS, plates and reinforcing bar—and a few other non-structural materials—falls under the purview of the Buy Clean California environmental legislation. The Buy Clean effort is only growing, spreading to other states and initiatives as greater strides are taken to reduce global warming. This article will discuss several of the fundamentals related to embodied carbon, the story behind HSS environmental impacts and what designers/steel suppliers need to know going forward.

Understanding the Basics of EPDs

An Environmental Product Declaration (EPD) reports the impact a building material has on the environment. An EPD is technically a third-party verified document that summarizes the environmental impacts of a product, derived from a science-based Life Cycle Assessment (LCA). In simpler terms, EPDs are often likened to nutrition labels for a food product, conveying how environmentally “healthy” a building material is.

Embodied carbon refers to the greenhouse gas emissions added to the atmosphere due to the manufacturing, transportation, installation, maintenance and disposal of building materials. One of the key ways an EPD documents environmental impacts is by reporting a Global Warming Potential (GWP) value for the material. The GWP value for steel is equivalent to measuring the relative amount of embodied carbon emitted to the atmosphere during only the manufacturing of the steel product, including all the inputs to process manufacturing such as electricity and various alloying materials. As greenhouse gasses linger in the atmosphere, they act as a blanket, insulating and warming the Earth. The lower the GWP value, the lower the embodied carbon emitted from that product, leading to less potential for global warming.

How Are EPDs and GWPs Developed?

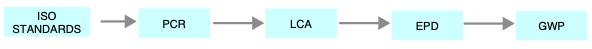

ISO 14025 and ISO 21930 Standards are a set of international standards that control environmental product declarations. These standards establish a core set of requirements to be considered in a Product Category Rule (PCR).

The Product Category Rule (PCR) provides the rules, requirements and guidelines for developing an EPD for a specific product category. The PCR instructs how the Life Cycle Assessment (LCA) should be conducted.

The Life Cycle Assessment (LCA) is the systematic analysis of the potential environmental impact of a product during its entire life cycle.

An Environmental Product Declaration (EPD) is a third-party verified document that summarizes the environmental impacts of a product (i.e., steel HSS) as a result of the LCA. There are different types of EPDs:

- Facility-specific EPD: An EPD from a single manufacturer and manufacturing facility of a product. A manufacturer of steel coil can have several steel mills. A facility-specific EPD must come from only one of a manufacturer’s steel mill facilities.

- Industry-average EPD: An EPD reporting the average EPD results developed from multiple manufacturers and multiple facilities of a steel product. See Figure 2 for an example of an industry-average EPD by STI for HSS, and refer to the link at the end of this article for a PDF download.

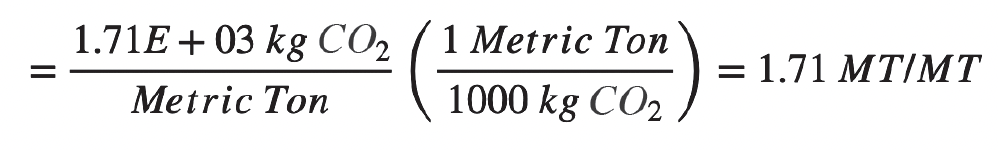

The Global Warming Potential (GWP) is a value reported in a product’s EPD, which, for steel, is measured in metric tons of CO2 equivalent per metric ton of steel. As mentioned, the GWP value for steel is equivalent to measuring the relative amount of embodied carbon emitted to the atmosphere during the manufacturing of the steel product. Technically, the GWP is a relative measure of how much energy the emissions of 1 metric ton of a greenhouse gas will absorb during a period of time compared to the emission of 1 metric ton of carbon dioxide (CO2). For example, the industry-average GWP for non-fabricated HSS is 1.71 metric tons of CO2 equivalent per metric ton of steel. This means that the overall emissions to manufacture 1 metric ton of HSS are equivalent to emissions of 1.71 metric tons of carbon dioxide. A product compliant with Buy Clean California requires an EPD reporting a GWP value for that product or material less than the threshold GWP value specified by Buy Clean for that product.

Buy Clean California

Now that we’ve laid the groundwork for embodied carbon and EPDs, let’s explore current Now that we’ve laid the groundwork for embodied carbon and EPDs, let’s explore current environmental legislation affecting building construction. The Buy Clean California Act (BCCA) requires that public projects in the State of California are to purchase only building material products with a GWP level below the mandated threshold as set by the Department of General Services. Essentially, its goal is to lower embodied carbon by affecting purchasing practices in building materials. There are a few items to note in the Buy Clean California Act:

- The legislation was passed in 2017, and the revised implementation date is July 1, 2022

- Applies to public projects in the state of California.

- Applies only to structural steel (HSS; plates; and hot-rolled sections such as WF, angles, channels and WT), concrete reinforcing steel, flat glass and mineral wool board insulation.

- Does not apply to other building materials, including (but not limited to) concrete, wood, mass timber, concrete masonry, clay masonry, cold-formed steel, etc. Legislation is currently pending to include other materials.

- BCCA requires a facility-specific EPD. The EPD must not be an industry-average EPD or an average reported GWP from multiple manufacturing facilities.

Buy Clean California is a change to the material procurement process—not the design process. In California, when those in the steel supply chain submit a project bid, they must also submit steel EPD(s) demonstrating the steel material that will be supplied for the project falls below the GWP threshold.

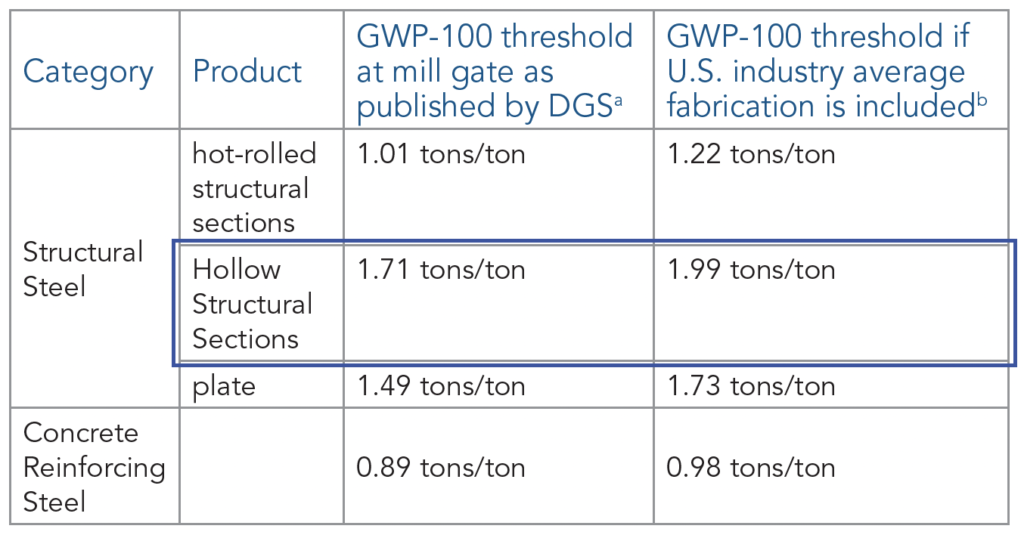

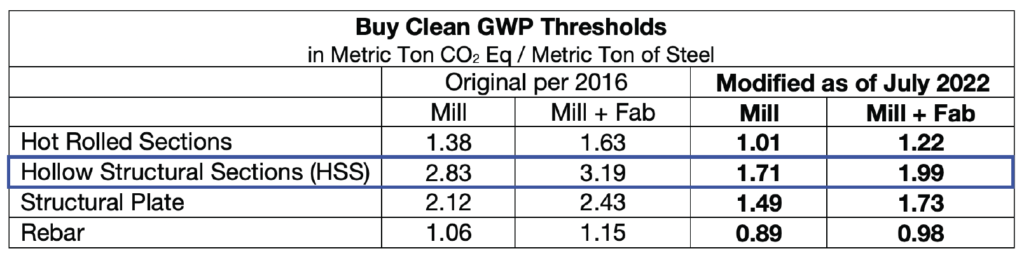

The Steel Tube Institute (STI), The American Institute of Steel Construction (AISC), The Concrete Reinforcing Steel Institute (CRSI), and The American Iron and Steel Institute (AISI) have developed a Quick Guide to Buy Clean California’s Steel Provisions. This document summarizes the maximum GWP threshold values required by Buy Clean in units of tons of CO2 equivalent per tons of steel and are listed in Table 1. Also listed in the Quick Guide are specific structural steel and steel rebar products that fall under Buy Clean provisions. Refer to the link at the end of this article to download the Quick Guide from the STI website.

Now that we know what the maximum GWP values are, how do we find the GWP values for the steel used for a project? The actual GWP values for steel products will be found in facility-specific EPDs published by steel mills. AISC and STI have published industry-average GWP values representing the average GWP values for the overall industry. These industry-wide EPDs can’t be used for compliance with Buy Clean California. However, fabricators eligible to use an industry-wide EPD published by AISC may submit the AISC EPDs as appropriate documentation to gain credit in programs such as LEED. The AISC industry-wide EPDs are also of value to designers estimating the embodied carbon of a structure during the conceptual design phase of the project.

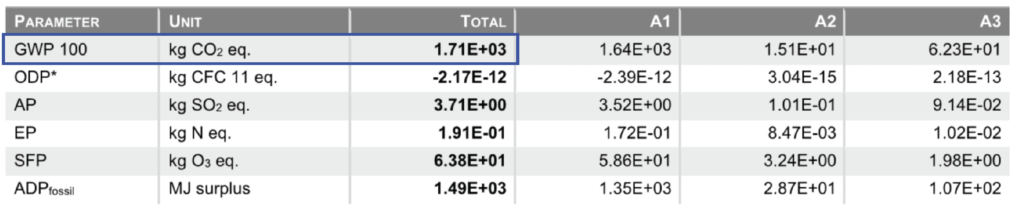

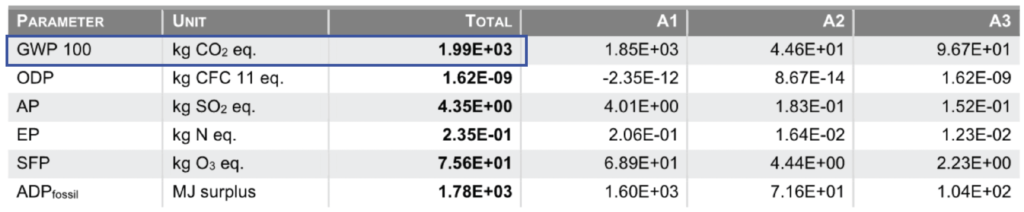

There are two main categories of steel EPDs you can obtain: fabricated or non-fabricated (before fabrication) steel EPDs. This is an important distinction to make, as the GWP values will be different for each and will be discussed in depth later in this article. Both GWP values are offered in Tables 2 and 3, depending on which EPD (fabricated or non-fabricated) you may need to reference for your project. Table 2 is an excerpt from the STI EPD for Industry-Average Non-Fabricated HSS dated July 1, 2021 (the current version when this article was written). Table 3 is an excerpt from the AISC/STI Industry-Average EPD for Fabricated HSS dated Feb. 3, 2022.

To illustrate, let us compare the STI industry-average EPD for non-fabricated HSS with the required GWP threshold per Buy Clean. Since the STI EPD reports non-fabricated HSS per Table 2, we compare this to non-fabricated GWP thresholds per Buy Clean California shown in the left column of Table 1.

Industry-average non-fabricated HSS GWP per STI EPD

is equivalent to the non-fabricated GWP threshold per Buy Clean California Act

= 1.71 MT/MT

If an HSS producer’s GWP is the same as the STI EPD industry-average GWP for non-fabricated HSS, which is equal to or less than the GWP threshold per Buy Clean, then it is acceptable. A similar evaluation would be performed for facility-specific EPDs received by mills and/or service centers to confirm compliance with Buy Clean California.

What’s the Story Behind the HSS EPD Numbers, and Where Are We Headed?

Since this legislation is fairly new, there has been a push in recent years to coordinate the several steps behind the GWP numbers—PCRs and LCAs—to prepare for the July 1, 2022, milestone for Buy Clean. For this reason, it is important to understand how the current GWP numbers were developed as well as what direction we anticipate we are headed.

For steel, the measure of carbon levels is taken “at the mill gate,” meaning the majority of the impact of steel to global warming comes from the production of steel at the mill. Effectively, when we try to reduce the embodied carbon of steel, we need to look at its life before it leaves the mill gate, before fabrication, before erection and before its final service life in a structure. Approximately 90 percent of the environmental impact of steel occurs before the steel piece leaves the mill gate, and 10 percent results from the fabrication portion of the steel supply process.

Understanding the embodied carbon levels in HSS requires background knowledge of the manufacturing of HSS at the mill. HSS is typically produced from flat sheet steel in coil form that is leveled and then cold-rolled into the HSS shapes we specify for our structures. There are two primary methods to manufacture steel coil used to produce HSS sections: Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF). Historically, HSS has been produced from steel coils that were manufactured using the old open-hearth or newer BOF method. The BOF method melts raw iron ore to extract pig iron to create new steel. A small percentage of scrap is used in this process. The EAF method uses recycled steel scrap as the primary feedstock to manufacture steel coil and electricity as an energy source, resulting in an overall lower amount of embodied carbon in HSS production. In recent years, coil manufacturers have found ways to overcome material ductility challenges inherent in EAF production, resulting in an increase in HSS production using EAF-manufactured coil in the United States. However, the majority of global HSS manufacturers outside the United States are largely dependent on BOF-manufactured coil.

It is important to parallel this HSS manufacturing discussion with the timeline for EPD and GWP numbers. In 2016, when the first HSS EPD was published, the only GWP data available for hot-rolled steel coils was based on an overall industry-average of coil production, which was dominated by BOF production domestically and globally. This GWP data did not accurately reflect the relative percentage of EAF and BOF coil being used in the production of HSS. This resulted in the 2016 industry-wide GWP value for HSS production being 2.83 metric tons of CO2 equivalent per metric ton of steel at the mill gate of the HSS producer. It is important to recognize that more than 90 percent of the GWP of HSS products is contributed by hot-rolled coil.

In an effort to provide a more accurate accounting of HSS GWP and meet the requirements of Buy Clean California, HSS producers decided to develop a new industry-wide EPD. The current EPD published on July 1, 2021, is based on a North American GWP value based on a closer approximation of BOF and EAF coil used in the HSS production process. In addition, as the GWP of the EAF process is closely tied to the CO2 impacts of electricity, the transition to a greater percentage of renewable energy is resulting in reduced GWP impacts for EAF steel products. The result is that the amount of embodied carbon associated with the manufacture of domestic HSS has decreased from 2.83 to 1.71 metric tons of CO2 equivalent per metric ton of steel at mill gate. Table 4 illustrates the decrease in GWP thresholds per Buy Clean that occurred between 2016 and 2022. This trend of decreasing GWP impacts will continue into the future as a higher percentage of EAF material is used and the electric grid becomes less fossil-fuel based.

In an effort to prepare for Buy Clean California to come into effect on July 1, 2021, HSS producers decided to develop a new industry-wide EPD by July 2021. The new EPD will now use a North American steel number for the LCA coil data, not global, which would represent a shift towards EAF-produced coils as the feed stock for HSS. In addition, there are also ongoing efforts to increase efficiency in the electric grid that powers EAF manufacturing. As the electric grid becomes more energy efficient and more fossil-free, the impact of steel HSS production on global warming would decrease. For all of these reasons, there is potential for the new GWP, and the amount of embodied carbon used to manufacture domestic HSS, to decrease. During the time this article is written, it remains to be seen if the new GWP number will be lower than the previous 2016 number.

What Do Designers Need to Know About EPD for HSS?

When selecting materials for a project, we can’t compare raw GWP values in EPDs between different materials (steel to concrete) or even within steel materials (WF to HSS). GWP values are based on the material’s unit of measurement: tons for steel, cubic yards for concrete, etc. The quantity of material used on a project to resist the same loading will vary greatly due to the difference in strength and stiffness of the materials. Therefore, to compare apples to apples, the structure as a whole would need to be analyzed and designed in each material separately to determine an estimated quantity for each material.

Image courtesy of AISC/Thorton Tomasetti

Multiplying each material quantity by its corresponding GWP number would result in a final embodied carbon level for that material. We can then compare these final carbon levels more accurately across materials. In essence, the GWP numbers shown on EPDs for different materials (steel vs. concrete, HSS vs. WF) can’t be directly compared to each other when deciding what material is more environmentally beneficial. The decision needs to be made in the context of the functional quantity of each material that will be required on a project.

A Whole Building Life Cycle Assessment (WBLCA) must consider multiple design alternatives that consider the use of all materials and products in the project. The selection of a specific framing material will also impact finishes, cladding and many aspects of the building. Regretfully, not all manufacturers have documented the GWP impacts of their materials and products in a manner that makes such overall comparisons reliable. Dissimilar materials and products can’t be compared to each other based on declared units.

Only a comparison based on functional units can reliably direct design decisions and only then when conducted within the context of a comprehensive building design.

Buy Clean California addresses the procurement of materials, not the design decisions related to the project. Contractors, subcontractors and procurement professionals need to ensure materials are being selected that have a GWP value less than the specified threshold. Designers can also benefit from specifying materials from specific producers that fall below the threshold and using the facility-specific GWP value in their WBLCAs. Designers may also choose to optimize materials in an effort to reduce environmental impacts on a project. However, care must be taken as minimizing steel tonnage is not always the most effective path to reduce GWP. A lighter steel member may require reinforcing at connections and thus additional fabrication work, increasing the overall GWP. A more effective approach for optimizing HSS design is to check HSS wall thicknesses at connections during design.

What Do We Need To Look For in an EPD?

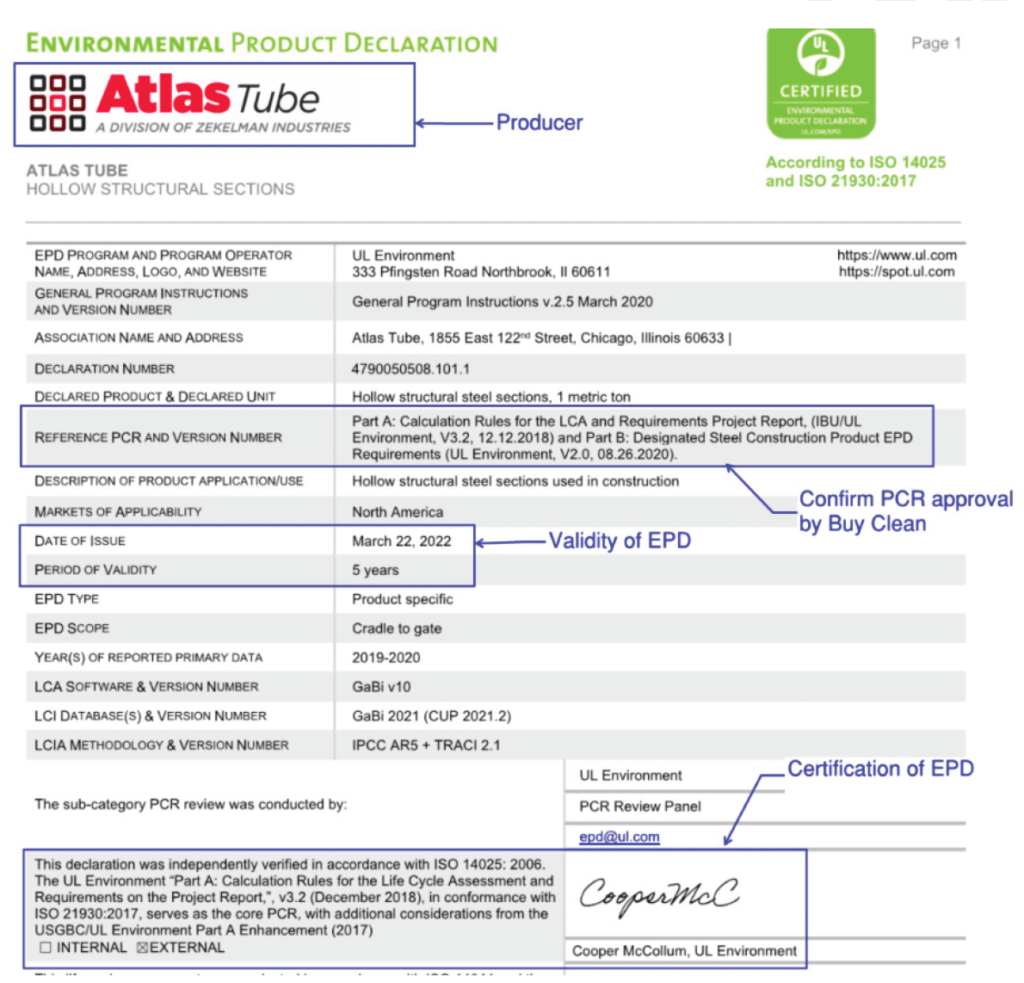

The following is a checklist of items to look for when reviewing an EPD:

- Who is the producer of the EPD?

- Which facility, or steel mill, is the EPD based on?

- Is the EPD date still valid, or has it expired?

- Is the Product Category Rule (PCR) approved by Buy Clean?

- Has the EPD been certified or verified by a third-party reviewer?

- Are the GWP values based on fabricated or non-fabricated steel?

- Does the GWP value fall below the required Buy Clean threshold for fabricated or non-fabricated steel? See Table 1 for GWP threshold values.

Figure 6 shows the start of a sample EPD (courtesy of Atlas Tube). For a more detailed review of a sample EPD, view the STI Revised Buy Clean Webinar linked at the end of this article.

Concluding Remarks

Now that we’ve fully discussed EPDs and the GWP values associated with HSS, it is important to note that this level of environmental transparency is consistent throughout the majority of the steel industry. Such transparency is not consistent, however, throughout all structural building materials. It is vital when choosing a structural material based on environmental attributes that a full and complete perspective be employed rather than a decision based on less-credible data. We have sadly learned in the analysis of some materials that unproven assumptions are being employed to make materials appear to be more environmentally beneficial.

“Dirty” steel mills are a thing of the past. The steel industry has evolved to now stand in the forefront of environmentally committed industries. This has occurred because of continuing commitment to increase the use of recycled material, improve manufacturing methods, promote greener electric grids and increase product performance. It is critical for all participants involved in the production of structural framing materials and the people designing with those materials to understand the basis of the GWP values being published in industry-wide and facility-specific EPDs.

The domestic structural steel industry has a strong, demonstrated commitment to the transparency necessary to address the challenges of global warming and reducing embodied carbon in steel products. For additional information on environmental impacts to HSS and other steel materials, please see the list of resources offered below. Feel free to also place an inquiry on the STI website at steeltubeinstitute.org/contact-us.

Resources

STI Sustainability Resources

Download industry-average non-fabricated and fabricated HSS EPDs.

Webinar On Demand

Watch the recorded webinar on the Revised Buy Clean California and the Steel Supply Chain.

Quick Guide

Download the Quick Guide to Buy Clean California’s Steel Provisions

Additional EPD Resources:

- STI Buy Clean California and the Steel Supply Chain webinar Q&A

- AISC industry-average EPDs

- Department of General Services (DGS) Buy Clean California Act

References

AISC and STI, 2016. “Environmental Product Declaration Fabricated Hollow Structural Sections,” American Institute of Steel Construction and the Steel Tube Institute.

Cross, J., Puchtel, M., and Anderson, J. May 2021. “Buy Clean California and the Steel Supply Chain,” Webinar, Steel Tube Institute.

Department of General Services Procurement Division. “Buy Clean California Act,” https://www.dgs.ca.gov/PD/Resources/Page-Content/Procurement-Division-Resources-List-Folder/Buy-Clean-California-Act, accessed 05.28.2021 (May 2021).

“A Quick Guide to Buy Clean California’s Steel Provisions,” American Institute of Steel Construction, Steel Tube Institute, Concrete Reinforcing Steel Institute, and the American Iron and Steel Institute.

Johnson, L. 2019. “An Accurate Declaration,” Modern Steel Construction, American Institute of Steel Construction, July 2019.

The International EPD System, www.environdec.com/home, accessed 05.28.2021.

September 2022