HSS Research

Tube in Tube Buckling Controlled Brace Research

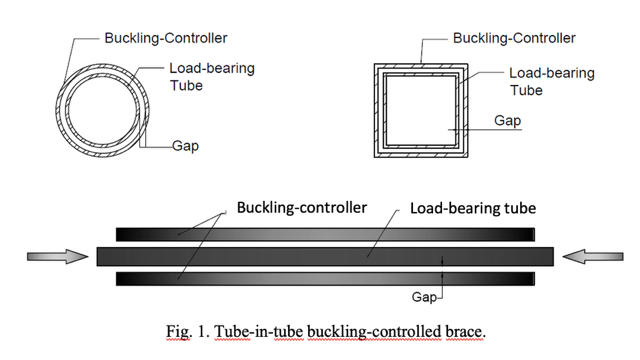

This ongoing research, sponsored by the Steel Tube Institute (STI) and AISC, investigates the effectiveness of encasing an HSS brace in another HSS to form a tube-in-tube buckling-controlled brace (TnT BCB). The encasing outer HSS is responsible for providing continuous lateral support and expected to prevent global buckling while delaying local buckling, without contributing to the load-carrying capacity of the inner HSS brace. The physical testing and finite-element analyses are performed by principal investigators, Professor Jay Shen, Associate Professor, Iowa State University and Professor Onur Seker, Associate Professor, Gebze Technical University.

Investigation of Local Slenderness Limits for Hollow and Concrete-Filled HSS Members used as Braces – Phase 1

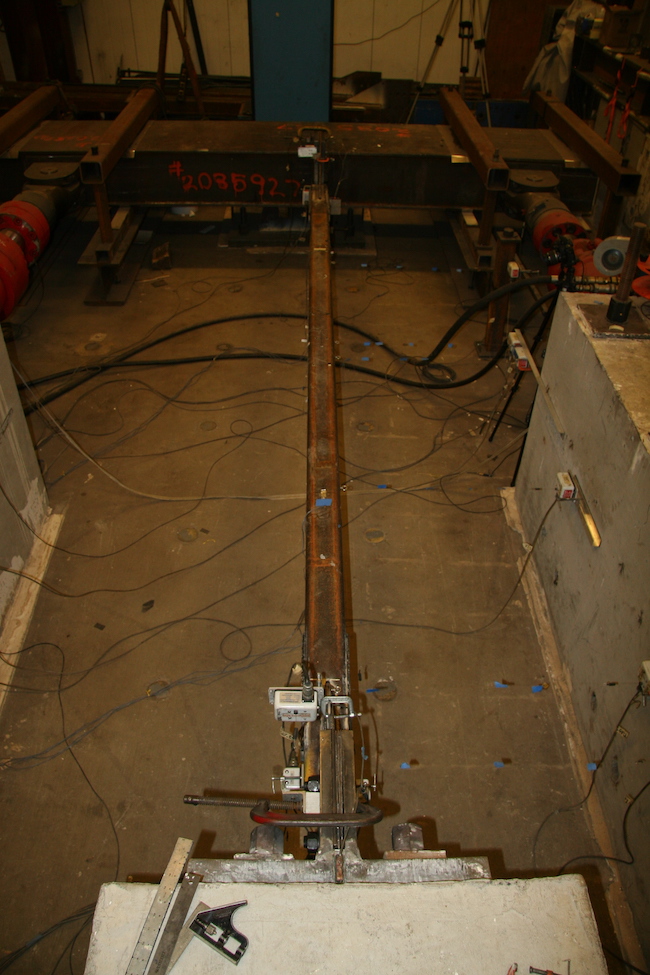

Dr. Dawn Lehman at the University of Washington, in collaboration with the Steel Tube Institute and American Institute of Steel Construction, and supported by Steel Tube Institute member producers, is conducting vital research to comprehend how local slenderness limits influence the design and behavior of braces made from Hollow Structural Section (HSS) in construction. This initiative, building on prior University of Washington research, seeks to provide insights crucial for an Ad Hoc Task Group working on slenderness limits and potential modifications to the existing AISC Specifications. By conducting comprehensive tests on various HSS brace sizes and shapes, the study aims to establish appropriate seismic design limits. The findings from this project are anticipated to influence the 2027 Seismic Specification (AISC 341), potentially broadening the range of braces available for seismic applications. The generous contribution of HSS for testing by Steel Tube Institute member producers plays a significant role in facilitating this investigation.

Rational Seismic Compactness Limits for HSS Members in Seismic Moment and Braced Frames – Phase 1

At the University of California – San Diego, supported by the Steel Tube Institute and American Institute of Steel Construction, Principal Investigator Dr. Chia-Ming Uang is investigating how size limits impact Hollow Structural Section (HSS) members in moment and braced frames during seismic activity. They aim to establish rational seismic width-thickness limits for HSS members within moment and braced frames. With the generous donation of HSS materials from the Steel Tube Institute members, the study anticipates broadening the available range of HSS columns and beams for use in seismic applications. The outcomes are expected to refine industry standards, potentially influencing changes in AISC Specifications and driving advancement in seismic construction.

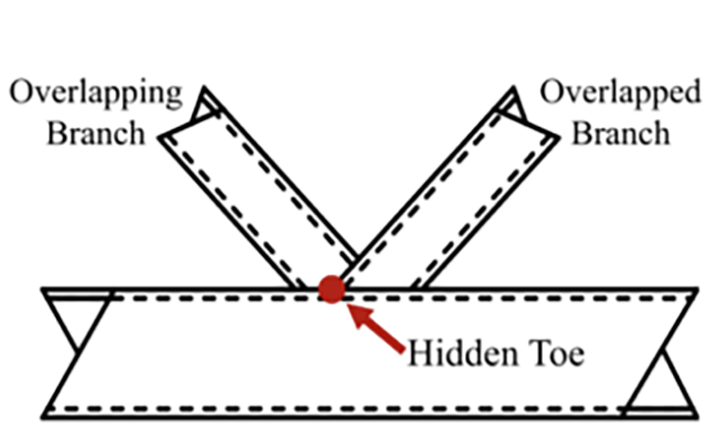

Hidden Toe Welds in RHS-to-RHS Overlapped K-Connections

Dr. Jeffrey Packer, the Bahen/Tanenbaum Professor of Civil Engineering at the University of Toronto, has accomplished groundbreaking research on welded trusses, supported by the Steel Tube Institute. Focusing on the impact of welding or not welding the hidden toe of the overlapped branch in overlapping HSS K-Connections, this study is detailed in the article “Overlapped HSS K-Connections: To Weld or Not Weld the Hidden Toe?” Alongside this publication, formal research reports are referenced in the ‘Reference’ section of the STI article, providing an in-depth understanding of this critical investigation into welded trusses.

RHS-to-RHS Zero-Gap K-Connections

Dr. Jeffrey Packer, the Bahen/Tanenbaum Professor of Civil Engineering at the University of Toronto, led groundbreaking research on welded trusses, made possible through sponsorship from the Steel Tube Institute. One of the primary investigations in this research centered on evaluating the impact of providing zero gap between two branches of an HSS K-Connection. This essential study is encapsulated in the article “Rectangular HSS K-Connections with Zero Gap,” with comprehensive research reports noted in the ‘Reference’ section of the corresponding STI article.