The Cutting Edge of Fabrication: Laser Cutting HSS

Fabricator Perspective: Mark Mercurio, regional sales manager at Mazak Optonics Corp.

We met with Mark Mercurio of Mazak Optonics to get an inside look at the cutting-edge technology of 3D laser cutting machines and the premium model, the 3D FABRI GEAR 400 III (Fabri Gear 400). Mark shared with us how fabricators can get more familiar with HSS laser cutting, the efficiencies gained in project speed and accuracy, and how fabricators can upgrade their business with the latest technology.

Q: Could you tell us about your background and experience in the laser equipment industry?

I have an electronic engineering background. After college, I started working in the laser industry, which I have been in for a little over 30 years. Most of that time was spent with Mazak Optonics Corp., which is the laser division of Mazak Corporation, one of the largest machine tool builders in the world.

I’ve worn many hats at Mazak. I started as a serviceman, then an applications engineer, and for 17 years I was an applications manager. Today, I’m a regional sales manager. So I have quite a bit of experience working with our own engineering staff in Japan and all of our products.

Q: What equipment and products does Mazak provide to support fabrication of hollow structural sections (HSS) or tubular members?

We’ve been building our Fabri Gear model for about 25 years, and it’s currently in its fourth generation. We make this machine in three different sizes: the 400 size, which has a 400-millimeter opening to the chuck and is about 16 inches in diameter; a 220 size, which is about 9 inches in diameter; and we make a 150 size, which is 6 inches in diameter. The chuck is what clamps the tube shapes into the machine and moves the material in the X-Dimension and the C-Dimension (rotation). Typical tube sizes start from 3/4 inch, so it’s important to note how the Fabri Gear 400 has an incredible capacity and can handle these much larger maximum chucking dimensions.

The Fabri Gear 400 is designed for not only HSS like round, squares and rectangular but also angle iron, channel and I-beam. We load them up on the in-feed side and you’d get a finished product on the other side. This machine comes in different lengths up to 50 feet, so it helps quite a bit in construction and fabrication of longer parts.

The typical way people do these types of structures is that they process them on multiple machine tools, but they’re so difficult to do in multiple handlings because they end up not being accurate. Each time you go from one station to the next, you lose your accuracy of the product.

Our Fabri Gear 400 can do the typical saw cutting, drilling, reaming, tapping, and vertical and horizontal machining operations all in one handling. What you get with laser cutting is a product that is very consistent. Even if you have to cut multiples of the same thing and you end up with multiple parts, they’re all the same size because we only handled it once.

What makes it very special is that it has a complete six-axis laser capability. The a-axis can rotate 360 degrees, and the b-axis can rotate plus or minus 135 degrees. So for different shapes of tube, it helps you get into small locations and process just like it was saw cut. Angle cutting through materials can be processed at up to 45 degrees, but larger angles can be achieved with proper fit and easy programming methods.

Q: Are there any examples of notable HSS projects that utilized Mazak’s equipment during the fabrication process?

Yes, there are quite a few. There is the Mazak World Technology Center, our showroom in Japan. We used a lot of tube construction up through the roof and the sidewalls — HSS with either angle iron or T-shaped beams that went through them to support that roof structure.

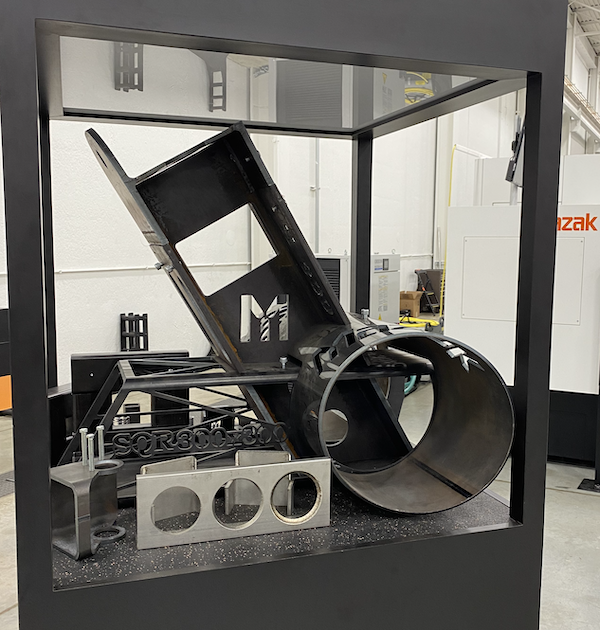

When it was built, they did all of the construction and welding at ground level rather than in the air like most structures. The fixtures pictured here are built so that as it gets jacked up, you could see them mate together perfectly. It’s a beautiful building and looks effortless. But it looks effortless because every one of these structural shapes were cut identical and accurately. It was the right length. It was the right shape. Identical.

Some others are the World Cup 2010 stadium in South Africa, the Baltic Arena in Poland, the Bratislava Terminal in Slovakia, the MyZiel Center in Germany, and the Capital Gate in the United Arab Emirates.

Q: When doing laser cuts through HSS members, cuts can involve putting vertical or horizontal slots accurately in an HSS member on opposite sides for plates to be fitted through the HSS. The HSS members typically range in dimensions from 6 inches to 16 inches in square, rectangular or round shapes. Could you describe Mazak equipment designed to make these precise types of laser cuts for slots?

With our Fabri Gear, we start with a four-chuck design. Whenever the tube is inside the machine, we’re supporting it with the chucks. In fact, we support the tube just by holding it up vertically and horizontally so that it’s very accurately being held down the centerline of the machine. That way, when we tell it to place a hole, we know where the shape is so we accurately can place that hole.

Now, you mentioned a through hole, and sometimes that gets interesting. Often when you’re looking at structural shapes today, squares are not actually square. They tend to slant or sometimes the sides are bowed out a little bit. After 25 years of building the Fabri Gear machine tool, we know that if you have a tube and you want to put a through hole through it, you have to know where the edge of that shape is. Our equipment accounts for the tolerances that come out of production of these steel sections with laser measurements or touch probing.

So, laser cutting is highly accurate. It’s one of the reasons why we are so successful at putting shaped members through other, different shapes.

Q: Can you tell us more about laser cutting I-shaped slots in HSS members so that wide flange beams can pass through them? Are these easy or complex cuts to make using Mazak equipment?

Pretty much any shape you need can be laser-processed. We have many machines throughout the U.S., and we have many different shapes available to us. The software is key. Typically, what a customer would do is draw their building with a Tekla format. We bring those Tekla drawings into our software, which will blow the drawing out into single-piece parts. It will tell us all the different shapes that were used and how many of them we need. Then it starts to what we call “nest.” It takes all of the pieces that were cut out and puts them together so that we can utilize a raw stick of material properly as we process it through the machine. It can do the same thing with I-beams, rounds and rectangles to efficiently use the material. As long as the shapes purchased are accurate in Tekla, the holes will be cut properly.

Q: For designers interested in specifying these complex cuts, how widely distributed would you say this equipment is among fabrication shops in the United States?

There’s a lot here in the Midwest. Recently, I visited a fabrication shop in Iowa and one in Indiana. There are many straight down the Mississippi River. They’re in a lot of steel service centers. And with several hundred installations all across North America, one can easily find a fabrication shop in their local area with these capabilities. You can send them the drawings, and they contract that work out.

Q: Can you describe how fabricators adjust Mazak equipment to accommodate various HSS shapes?

So, the Fabri Gear 400 can work on shapes from a 3/4-inch round or square all the way up to a 16-inch round, 12-inch square. In between those, you could cut a round, and then the next part could be a rectangle, and the next part could be an I-beam. The way we carry the material to the chucks and how they close on the material means there’s really nothing an operator needs to do to change the shape or sizes of tube structures.

With that said, it has such a large range from 3/4-inch all the way to 16 inches, so in that material range, there are a couple jaw changes. We need to make the jaws a little smaller or a little larger so that we can clamp. But usually, there are about three size ranges you can switch from, and as long as all the pieces are within that size range, there’s nothing an operator needs to do. All of the clamping is automatic, the feeding to the machine is automatic and all the support is automatic.

Q: Are there particular types of HSS applications that laser cutting is best suited for?

We can take really any shape. If you’re just doing straight-end cuts, a tube laser may not be the best idea because it’s an expensive machine tool. You could probably just use a saw. But as soon as you do an end cut or an internal cut that is not a standard shape, the tube laser is the way to go.

Q: What distinguishes Mazak’s equipment from other laser-cutting machines available in the domestic market? Are there any features specific to HSS fabrication that are unique to Mazak’s equipment?

The unique feature of the Mazak machine is that it has four chucks. There’s not another machine out there that utilizes four chucks for processing. An important thing about handling and cutting structural shapes is to know where the product is so that you can accurately place the cuts and the holes on the product.

When I look at the specifications of this machine compared to others that are out there, this one is also typically bigger and can hold bigger and heavier pipes. You need to be careful about how much your raw material weighs and how much weight per foot you have at the chucks. This is one of the biggest machines out there when it comes to the maximum weight it can carry. It is also a completely three-dimensional machine, so it can do angle cutting, champhers and weld preparation features.

Q: If we were to ask a fabricator how using Mazak’s laser equipment has changed or improved their process, what do you think they would say?

Our laser equipment shrinks the time frame of projects. It allows it to be done all in one process. Because you could put any shape onto the end of a cut or put any shape into a cut, it’s allowed many fabricators to redesign how they build things. They’re no longer handcuffed to the different types of equipment they have in the shop, which would be saws, drills and machining centers. So there is accuracy and speed of the first end process.

What we found is that conventional methods of building with tube constructions took a long time to produce and then be machined. It was a very long time before you ever got to the welding process. In our own construction, we found that we could generate a program, generate fixtures to hold the parts, laser cut it, and assemble and weld very quickly.

But where most people tell me they save more time, and this one’s hard to quantify, is that if they’re building a product that has multiple tubes that have to interconnect, it’s usually around 30% faster in assembly and welding. Every piece of pipe is identical, so people need less hammering to fit things together, and they use less weld because it’s a proper fit.

Q: What steps would you recommend for fabricators interested in acquiring the Mazak equipment we’ve discussed? Could you also give insight into the learning curve or training required for fabricators to learn how to effectively operate the equipment?

They could always contact us at our website at MazakOptonics.com and look up their local regional manager on the contact page.

When we have a customer purchase this machine, they usually purchase it with our software. We train them for about two-and-a-half weeks once the machine is installed. We will spend time doing just straight up and down two-dimensional cutting on the laser. Then we teach them three-dimensional setup and maintenance. And then we do three-dimensional cutting. We like to make sure that the operator and the programmer are very involved so that if they have any difficult shapes or processes they need to do, they know how the software can help the operator out. We also like to make sure the software person programming it knows how the machine tool runs so that it can be programmed properly from the get-go. Then, usually, I like to let the customers run the machine for about a month before we go back for three more days for a training refresh.

Q: Do you have any valuable advice for fabricators looking to expand their shop with state-of-the-art equipment?

I always tell fabricators who do both flat and tubing to look at your shop. What you do today on the flat side of your business with flat sheet material, lasers, press breaks and turret punch, all of these different machine tools are cutting edge in 2023. But most everything we build today from sheet metal and buildings has got some tube structure underneath it.

So I tell them to look at the tubing side of their business, and they see that their technology is from the 1970s. By upgrading to modern tech and lasers, you can get extremely accurate cuts. My advice then boils down to, get your tubing business to match your flat sheet side in terms of tech, and you’ll be quite amazed at what you can build.

Beam-to-HSS Column Moment Connections Using Laser-Cut Columns

Creating a connection with moment capacity between a wide flange beam and an HSS column can be done numerous ways with varying degrees of difficulty and complexity. This article discusses the intricacies of those connections, showcasing how innovative approaches to beam-to-column connections, using laser cutting technology, enable high-precision cuts that can be performed quickly and economically. Discover more about how this innovative technology is advancing the fabrication process.