HSS Splice Design – Part 2: Simplifying HSS Field Splices With One-Sided Bolting

By: Ted Goldstein, P.E., Atlas Tube,

with input from David Brown, BlindBolt, and

Matthew B. Kawczenski, P.E., S.E., F.SEI, Lindapter International

September 2025

HSS members bring a unique combination of strength, efficiency, and aesthetics to structural design. Their efficient, balanced section properties allow engineers to reduce the tonnage of members loaded in compression, biaxial bending, or torsion. The same closed, hollow shape that delivers these advantages can present challenges for certain connections. Field splices, in particular, have traditionally been performed by welding due to lack of access to the interior of the member. The need to bevel and back weld, along with the attachment and removal of temporary connections to hold the connection in place while it is welded, mean that welded HSS splices are generally more labor intensive than bolted options. Such welded connections make sense in some cases, such as when tensile or moment demand is very high, or when aesthetic concerns dictate connection type, and their design is examined in part one of this series.

This paper addresses the selection and design of in-line bolted splices. Bolted splice connections such as end-plates, which are made by shop-welding attachments to the exterior of the HSS, are well-established and appropriate in situations where space is adequate and aesthetics are not a concern, and will be addressed in part three of this series.

To avoid the challenges of welding HSS splices in the field, a number of products have been released that allow fasteners to be installed from one side. Those products include various one-sided fasteners that can be installed from the exterior of the HSS: expansion wedge bolts, such as Hollo-Bolt, an internal toggle fastener, Blind Bolt, and fasteners with collapsible split washers, as well as a structural nut keeper, Shuriken that holds a standard nut inside the HSS to allow installation of a standard bolt from the exterior. Taken together, these products allow for splices that can be fabricated and erected faster and with less labor than welded splices. Each of these products has pros and cons that relate to capacity, cost, hole size, simplicity, and other factors. An overview of these and other one-sided fastener options, including installation considerations, can be found in the Steel Tube Institute article, “HSS Blind Structural Fasteners”.

Splice Configurations

To address these erection challenges, there are several splice configurations that can be utilized. The best configuration for a given project depends on the geometry, aesthetic requirements, and the magnitude and direction of loading (i.e., axial, shear, moment, torsion). The various bolted splice geometries can be grouped into 5 general types: internal, double shear, external, coped, and covered, which are explained in more detail in this section. Each of the splice configurations presented here are adaptable for use with Blind Bolts, Hollo Bolts, Shuriken, or other one sided fastening solutions.

A consideration unique to bolted HSS splices is the need to account for the direction from which members will be lifted into place. Whereas in an open section, a splice plate can always be positioned after the member has been lifted into place, elements mounted on the interior of the HSS must be attached before the member is lifted, and arranged in such a way that it will not block erection.

For example, in an HSS column splice, plates can protrude beyond the top of the lower column since the upper column can be dropped in place from above (i.e., along the longitudinal axis of the member). That same connection detail works for a cantilevered HSS beam, but not for an HSS beam supported at both ends, since the protruding plates would prevent the member from being dropped into place. The “external”, “coped” and “covered” configurations presented here are generally applicable to cases where one member cannot be slid into place along its longitudinal axis like a column splice.

In general, the configurations presented in this section show the splice plates bolted to both members being spliced, but in some cases it is possible to shop-weld the splice plates to one member and field-bolt to the other, such as in Figure 1. This approach has the benefit of reducing the number of fasteners, but reduces the amount of adjustability in the connection, making it more difficult to align the pieces in the field.

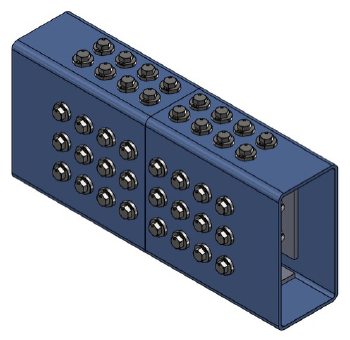

Internal: splice plates are located on the interior of the HSS only, as shown in Figure 2. This configuration is simple and aesthetically clean. It works well for splicing columns or cantilevered beams since in those cases the member can be moved into place along its longitudinal axis, allowing the splice plates to be mounted to one member ahead of time and slid into the other member during erection.

If HSS members with different wall thicknesses are to be spliced internally, a shim plate will be required between the splice plate and the wall of the member with the thinner wall thickness. The shim plate should be shop-bolted to the member with the thinner wall since it will not be possible to access the interior of the connection in the field.

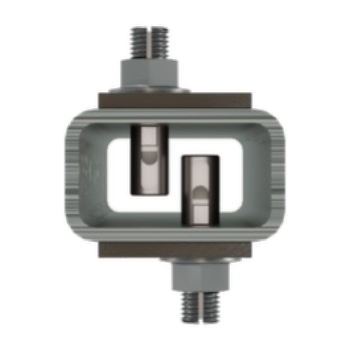

Double Shear: splice plates are located on both the interior and the exterior of the HSS, as shown in Figure 3. This configuration reduces the number of fasteners required by half along with a corresponding reduction in the size of the splice plates. As with an internal splice, a double shear splice must be erected along the long axis of the member. It also requires more precision during erection since one of the members has to fit around the inner plates and within the outer plates. If aesthetically acceptable, a bevel or bend in the splice plates can ease erection, as seen in the image on the [right]. Alternately, an additional row of bolts can be included on the shop-bolted side of the interior plates to hold them in place, with the exterior plates installed only after the two members have been mated in the field.

|  |

External: splice plates are located on the exterior of the HSS only, as shown in Figures 4 and 5. This arrangement allows erection from any direction without obstruction. To prevent the need to lift the splice plates separately, two plates (e.g., the “top” and “right” plates) can be mounted to one member, while the other two plates (e.g., the “left and “bottom” plates) can be mounted to the second member before the two members are mated. This approach is simple and reduces the likelihood of conflicts within the interior of the tube, though the resulting connection will be less visually clean than with an interior splice.

In the case of exterior splices made with Shuriken, the Shuriken should be installed on a thin mounting plate and bolted to the interior of the tube using a pair a dedicated bolts that do not pass through the splice plate. For connections made with Hollo Bolt, Blind Bolt, or other one-sided fasteners, the interior mounting plates are not required.

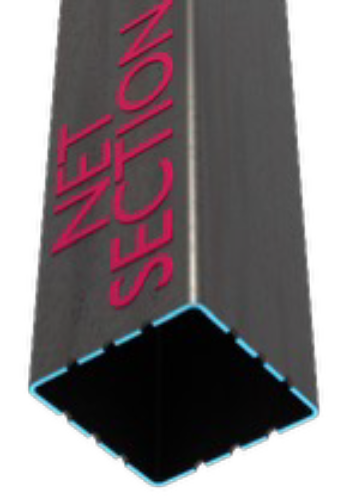

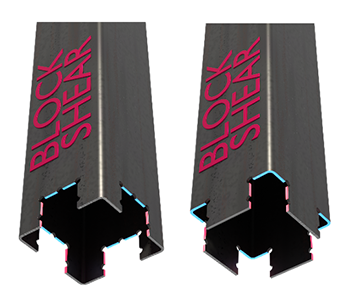

Coped: HSS members are profiled with interlocking copes and interior splice plates, as shown in Figure 6. This arrangement yields the clean aesthetics of an interior splice while allowing erection perpendicular to the long axis of the member. The coped HSS splice entails additional fabrication and waste, and generally has less capacity than square-cut splices, since most or all of the connection force must be transmitted through half of the member’s total area. For these reasons, coped splices are usually limited to applications where aesthetics are a prime concern.

Covered: internal splice plates are mounted on both members and covered from two sides after the pieces are brought into alignment, as shown in Figure 7. Covered HSS splices are the most complex arrangement of those discussed here, but have clean aesthetics and can be designed for large forces, while allowing erection perpendicular to the long axis of the member.

Limit States

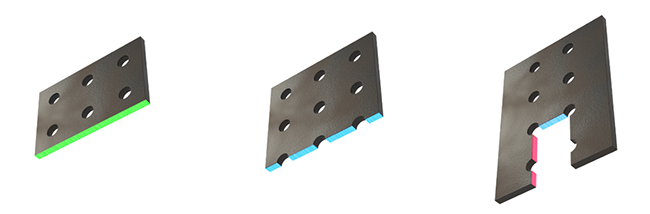

From an engineering standpoint, designing a bolted splice of an HSS member is very similar to designing a wide-flange splice where bolts would be accessible. The limit states that need to be checked are noted below. In the accompanying diagrams, green indicates area subject to yielding, blue indicates material subject to shear rupture, and pink indicates material subject to tension rupture.

When using one-sided fasteners, it is important for the designer to verify the capacity of the fastener through appropriate means. This can be done via a third party evaluation report such as an ICC-ES or IAPMO-UES report. Structural nut keepers do not require an evaluation report since they do not participate in the load path.

Both staggered configurations can be used to avoid conflicts between fasteners on adjacent faces, and on opposite faces when space is very tight. In extremely tight conditions, fasteners can be staggered both axially and circumferentially to prevent conflicts.

Fasteners

- Fastener shear strength: For one-sided fasteners, allowable loads are included in manufacturer’s literature. For structural nut keepers, standard bolt capacity can be looked up in the AISC Steel Construction Manual Part 7, or calculated using the governing code.

- Fastener slip resistance: Not always applicable, but may be required by code for some connections, or when the engineer judges that movement of the joint could affect stability or serviceability.

HSS Member

- Bearing: Applicable for loading in axial compression. Care must be taken to only include the area where the two members are in contact. If the two members have different wall thicknesses, the radii of the corners will also be different, resulting in reduced bearing area. In such cases, bearing area can be conservatively calculated as the sum for all four faces of the thicker section’s workable flat times the thinner section’s design wall thickness.

- Net section rupture: Applicable for axial tension and bending. In axial tension, the net section area is the gross area minus the area of the holes, as shown in Figure 8. When analyzing moment capacity, the net area of the tension flange is the area of the workable flat plus half the corner area on each side, as shown in Figure 9. For connections with bolts on only two sides, net section rupture capacity must account for shear lag.

Figure 10: Possible block shear boundaries for HSS splices subject to axial tension.

- Bolt hole bearing and tearout: Applicable for all loading except axial compression loads resisted by bearing. Increasing bolt spacing, edge distance or HSS wall thickness can increase the capacity associated with this limit state.

- Block Shear: Applicable for axial tension and bending. Because an HSS cross section is a closed loop, block shear can occur either on the faces of the member, or at the corners, as shown in Figure 10.

Splice Plates

- Gross section yielding: Applicable to axial tension, bending, and compression loads not resisted by bearing.

- Net section rupture: Applicable to axial tension and bending.

- Bolt hole bearing and tearout: Applicable for all loading except axial compression loads resisted by bearing. Block Shear: Applicable for all loading except axial compression.

- Splice plate buckling: Applicable for axial compression loads not resisted by bearing.

Each connection between a splice plate and a face of the HSS can carry axial load and shear. Moments imposed on the connection can be resolved as tension on one side, and compression on the other (with tension generally governing unless a portion of the bearing surface on the compression side has been removed). Torque can be resolved as shear in opposite directions on opposing splice plates. (i.e., all shear forces acting either clockwise or counter-clockwise.)

Accounting for Internal Congestion

As with any bolted connection clearances must be accounted for to avoid conflicts between fasteners on adjacent faces of the member. For wide-flange splices this issue may arise if bolts through the flange are located very close to bolts through the web. Clearance issues come up more frequently with bolted HSS splices because the various one-sided bolting products often take up more space than a normal nut or bolt on the interior of the HSS, and because the space is enclosed. Whether it is the shank of a one-sided fastener extending into the hollow of the HSS, or a structural nut keeper mounted therein, attention must be paid to ensure that Bolts on one face of the tube will not conflict with those on an adjacent or opposite face. This issue is especially common in smaller HSS sections.

Where conflicts are identified, it may be possible to stagger fasteners to avoid them. There are two types of stagger that can be used to alleviate internal conflicts:

- Axial staggering: locating fasteners at different points along the length of the HSS member, as shown in Figure 12.

- Circumferential staggering: locating fasteners off center on each face in the same direction (i.e., clockwise or counter-clockwise), as shown in Figure 13.

Example Calculations

This article references several one-sided fastening solutions available in the marketplace. To illustrate how some of these systems can be applied in HSS splice design, example calculations and/or details are provided for three specific products: Hollo-Bolt (Lindapter), Blind Bolt (Blind Bolt Company), and Shuriken (Atlas Tube). These examples were developed by the respective manufacturers—STI associate and member companies who contributed to or reviewed the technical content of this article. Example calculations can be found at here.

Conclusion

The various one-sided bolting products on the market have made clean, efficient HSS splices possible without need for field-welding. There are some design considerations unique to bolted HSS splices, but the design process is reasonably simple and comparable to that used when splicing wide flange members or other open shapes.

Related Resources

HSS Splice Design | Part 1: Rectangular Column Field Welded Moment Splices

Explore two practical examples of welded splice connection designs for HSS columns and chords – showcasing how PJP splices can del…

HSS Splice Design | Part 3: Rectangular HSS Bolted End-Plate Connections Under Bending Moment

This article presents practical design approaches for bolted end-plate connections in rectangular HSS members subjected to bending…

HSS Splice Design Examples: One-Sided Bolting

Discover practical, real-world solutions for HSS splice connections with detailed drawings and proven one-sided bolted designs. Se…

HSS Blind Structural Fasteners

This article introduces one-sided fasteners for connecting to HSS members, outlining proprietary options available in the marketp…

HSS Splice Design Examples: One-Sided Bolting

Discover practical, real-world solutions for HSS splice connections with detailed drawings and proven one-sided bolted designs. See splice example calculations with limit state checks from Atlas Tube and Blindbolt, and review Lindapter’s one-sided fastener options with connection details and available capacities. Click through to explore practical splice examples prepared by engineers.