Composite Column Connections

By Kim Olson, PE

Technical Consultant, Steel Tube Institute

In the previous month’s article, Dr. Jeffrey Packer offered insight into the advantages of filling a hollow steel member with concrete and how this composite section affects truss connection designs. This article will explore another common type of connection: one to a concrete-filled HSS column.

Concrete fill adds stiffness and compressive strength to a tube column and also reduces the potential for local buckling. Furthermore, the strength of the concrete is increased due to the confinement provided by the HSS. Concrete spalling is prevented by the tube, and shrinkage and creep of the concrete is greatly reduced.

For the design of composite columns, full composite action resulting from a good bond between the steel and concrete is assumed and results in strain compatibility between the two materials.

Shear Connections

Connections to composite columns can be achieved by loading the column in bearing or connecting to the face of the column. Some structural codes require the column be loaded in bearing at its top (roof) level. This can be accomplished by running the beam over the column so it bears on grout and a bearing plate. Doing this at each level requires more complicated detailing and, therefore, increases costs. However, this allows direct transfer of the beam load to the concrete core and steel shell. While this connection is extremely efficient for single-story construction, it creates inefficiencies for multitier columns and multistory structures. This connection requires the column to start and stop at each beam bearing elevation and increases the number of members for erection.

At lower levels, a more economical option is a traditional connection to the face of the HSS wall using a shear tab, WT or double angles. Connecting to the face of the column without penetrating it increases efficiency in both material and fabrication labor as well as increases erection economies for the multitier column. However, strain compatibility can no longer be assumed in the region of the connection. In this case, the load transfer to the column is primarily achieved by the joint rotating due to the eccentricity of the load, causing the steel tube to “pinch” into the concrete core, which has a positive impact on the friction in the steel-concrete interface. In this case, the load transfer from the steel wall to the concrete core depends on the bond between the steel and concrete, with the deformation of the connection providing bearing and friction. If the load being delivered to the concrete core exceeds that which can be provided, a through plate connection can be utilized, which would bear on the concrete core and transfer the force. This ends up being a much more costly connection as the HSS walls have to be slotted and a plate threaded through. The through plate also impedes and complicates the concreting process.

When a shear force is expected to be transmitted to the concrete core of a concrete-filled tube (CFT) as a compression force, direct bond is commonly used as the force transfer mechanism. The bond stress between the concrete and the steel tube must be checked. It may be considered that the bond stress, uniformly distributed between the midpoints of the columns above and below, can transfer the force. The check for this is given in AISC 360-16 by Equation (I6-5) as follows:

Rn = pbLinFin

where

Rn = nominal bond strength, kips

pb = perimeter of steel-concrete bond interface within the composite cross section, in.

Lin = load introduction length, determined in accordance with Section I6.4, in.

Fin = nominal bond stress, ksi

= 12t ⁄ H2 ≤ 0.1, ksi for rectangular HSS

= 30t ⁄ D2 ≤ 0.2, ksi for circular HSS

The experimental data for bond strength for these members has a large scatter, resulting in a low phi of 0.50 and a high omega of 3.

For the design of the connection, it is recommended the designer follow the same criteria as would be used for unfilled HSS.

If the concrete is being used for a dual purpose — load capacity and fire protection — the above recommendations for connections should be negated. In a fire event, the steel and concrete will expand at different rates with the steel eventually softening and shedding its load to the concrete. Therefore, it is not recommended that a simple shear plate be used unless the members are being protected from fire by other means (spray-applied fire proofing, intumescent paint, etc). If not, a through plate, which provides direct load transfer to the concrete, should be employed (see Figure 1).

Semirigid Connections

In general, the connection strength and stiffness of a concrete-filled tube will be higher than its unfilled counterpart, but in some cases, the rotation capacity will decrease. This is of concern for joints transferring axial and/or moments to the column. As the joint rotates, the compression side will be stiffer because the loads are resisted by the concrete infill. The tension side can only marginally deform. The deformation is typically not enough to form a yield line. The result is a small deformation capacity due to punching shear failures.

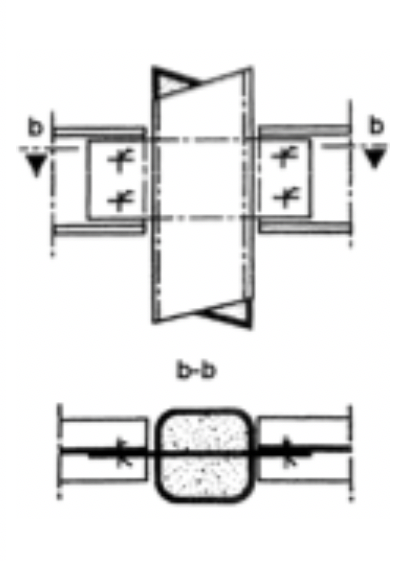

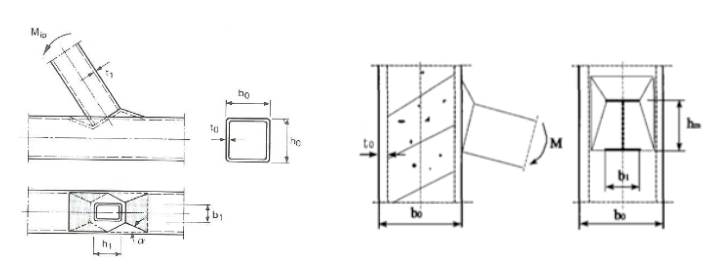

For axially loaded connections, the yield line models developed for unfilled HSS can be used but should be modified for connections to composite columns. For rectangular hollow sections (RHS), Figure 1 illustrates the yield line mechanism for plastification under in-plane bending for an unfilled HSS chord member. Figure 2 illustrates how the concrete fill precludes the deformation of the HSS wall by the compression flange, resulting in a modified yield line. Additionally, the concrete fill precludes the column side wall from deforming into the section (see Figure 3), which provides additional stiffness to the loaded wall. As a result, Lu (1997) reported an increase in connection strength of up to more than 30% with concrete-filled tubes for axially loaded connections to RHS.

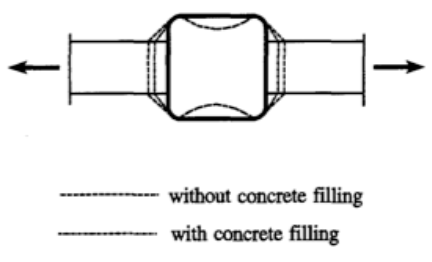

De Winkel (1998) reported in his testing that axially loaded plate connections to composite circular hollow sections (CHS) failed by buckling of the plate member in compression and plate yielding, followed by punching shear in the column in tension. In general, axial connections to unfilled CHS will fail due to column plastification, whereas connections to filled CHS fail by punching shear in tension and buckling of the plates in compression.

There have been many studies and papers written pertaining to moment connections to CFTs, especially as they pertain to cyclic loading. However, as of today, there has not been a consensus document written, making them difficult to employ in today’s construction projects.

References

AISC. 2016. “Specification for Structural Steel Buildings”, ANSI/AISC 360-16, American Institute of Steel Construction, Chicago, IL.

Dunberry, E., LeBlanc, D. and Redwood, R.G., 1987: Cross-Section Strength of Concrete Filled HSS Columns at Simple Beam Connections, Canadian Journal of Civil Engineering, Vol. 14, No. 3, pp. 408-417.

Kodur, V. K. A. and MacKinnon, D. H., 2000: Design of Concrete Filled Hollow Section Columns for Fire Endurance. Engineering Journal, American Institute of Steel Construction, Vol. 37, No. 1, pp. 13-24.

Kurobane, Y., Packer, J.A., Wardenier, N., and Yeomans, N., 2004. “Design Guide for Structural Hollow Section Column Connections,” CIDECT Design Guide No. 9, CIDECT, Geneva, Switzerland.

Lu, L.H., 1997: The static strength of I-beam to rectangular hollow section column connections. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands.

Packer, J.A., Wardenier, J., Zhao, X.L., van der Vegte, G.J., and Kurobane, Y., 2009, CIDECT Design Guide No. 3, 2nd edition, CIDECT, Geneva, Switzerland.

Winkel, G.D. de, 1998: The Static Strength of I-beam to Circular Hollow Section Column Connections. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands.

July 2020