Bolting to HSS Members

By Jason Ericksen, SE

FORSE Consulting, Technical Consultant to the Steel Tube Institute

Welding is generally used for connections to HSS members. However, there are also methods for bolting to HSS members. The main challenge for using bolts with HSS members is access to the interior of the member – conventional bolts require access to both sides of the bolt during installation.

Conventional high-strength bolts can easily be used when they are located near the end of the member or when access holes are used. Access holes can be placed in a location where they are not critical to the strength of the member or the holes can be sealed and/or reinforced such that the section meets the strength requirements. Another common option is to shop weld plates or other connection material to the HSS in such a manner that allows the members to be bolted together in the field.

The American Institute of Steel Construction (AISC) has published discussions on using bolts with HSS members in Chapter 3 of Design Guide #24 “Hollow Structural Section Connections” and Part 7 of the Steel Construction Manual, in section “Special Considerations for Hollow Structural Sections”. Both of these resources discuss the following options for bolting to an HSS member:

- Through-bolts

- Blind bolts

- Threaded Studs

- Flow-drilled bolts

These resources also discuss three limits states that may apply to the HSS member for the design of a bolted connection.

- Bolt bearing in the HSS wall: The bearing strength at bolt holes is determined from Section J3.10 in the AISC Specification, just as it is for any other connected part. Section J3.10(c) applies specifically to through-bolts and requires that the bearing strength is determined from Section J7(a) using Equation J7-1.

- Pull-out from tension in one fastener: Section 3.2 of Design Guide #24 provides an equation for the pull-out strength of a single fastener through an HSS wall. The equation is based on the shear rupture of a surface through the thickness of the HSS wall defined by the diameter of the part in contact with the inner wall.

- HSS wall distortion: Section 3.2 of Design Guide #24 recommends that HSS wall distortion can be accounted for by using the criteria in Section K2 of the AISC Specification for chord wall plastification by treating the area defined by the bolt group as the branch in a T-connection.

Through-bolts

An entire article about through-bolts can be found here.

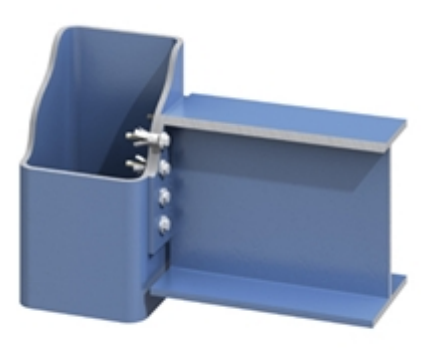

Blind bolts (one-sided bolting)

Blind bolts are specially manufactured to allow the bolt to be installed without access to both sides of the joint. Typically, a wedge or similar mechanism on the interior side expands as the bolt is tightened to form the contact on the interior surface. Blind bolts are generally designed for shear but some manufacturers can provide bolts for slip-critical or tension conditions. The connections are designed using bolt design strength values provided by the manufacturer and the three limit states discussed above for the HSS member. Shear capacities of these products are generally in line with typical high-strength bolts, while tension values are significantly less. Some bolt manufacturers have obtained ICC-ES certification for their products which can simplify the approval process.

Threaded studs

Threaded studs can be field or shop welded to an HSS member with a stud-welding gun. The connection design is similar to a typical bolted connection with the strength of the stud in tension or shear based on the manufacturer’s guidelines. In addition, the HSS must be checked for wall distortion when the studs are in tension. The bolt holes in the connected parts are generally countersunk in order to clear the fillet weld between the stud and the HSS wall. Threaded studs are typically available in ¾ in. and 7/8 in. diameters.

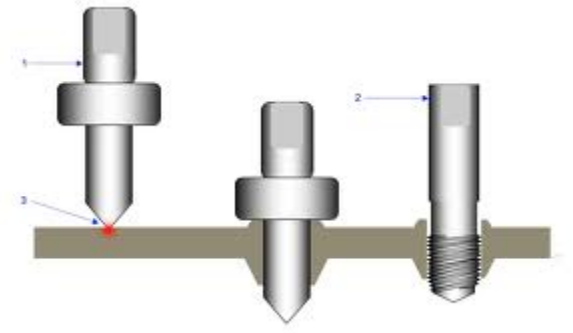

Flow-drilled bolts

Flow-drilling is a process that creates a threaded hole in an HSS wall. The process forces a hole through the HSS wall that forms an interior truncated hollow cone and hardens the steel. A tap is used to create the threads after the drilling is complete. The process yields a threaded hole that has dimensions and hardness properties similar to that of a heavy hex nut. More information on the process is available in CIDECT Design Guide #9 for Structural Hollow Section Column Connections and from the manufacturer, Flowdrill b.v. (flowdrill.nl).

Additional Resources

Design Guide #24 has design examples that illustrate how to apply the three limit states that apply to the HSS member for bolted connections. The series of design guides published by CIDECT provides a wealth of information on the use and connections of HSS members, including bolting. These design guides are available for free download from the HSS Channel on the AISC website (aisc.org/hss). The book “Hollow Structural Section Connection and Trusses” by J.A. Packer and J.E. Henderson is a valuable reference for the design of connections to HSS.

Several blind bolt manufacturers were identified during research for this article:

ONESIDE structural Fastener from Ajax Fasteners (ajaxfast.com)

Hollo-Bolt by Lindapter* (lindapter.com)

Blind Bolt by Blind Bolt Company (blindbolt.com), and

Box Bolt by LNA Solutions* (lnasolutions.com)

*Indicates ICC-ES certification available.

May 2014