2026 National Electrical Code® (NEC®) Changes

The National Electrical Code is used in all 50 of the United States, as well as several countries in North, Central, and South America. It is updated every three years. As always, the NEC experienced several changes in the 2026 edition. This article discusses some of the changes that specifiers, inspectors, and installers of steel conduit and tubing will need to know.

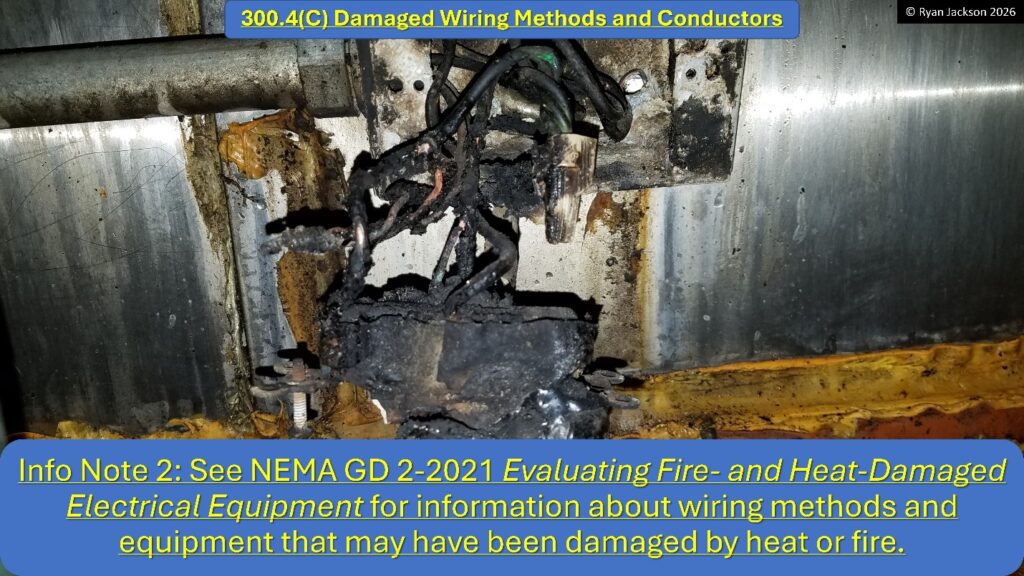

300.4 Limitations.

Damaged equipment must now be replaced.

300.4 Limitations.

(C) Damaged Wiring Methods and Conductors. Wiring methods and conductors that have been damaged by water, fire, overloading, corrosion, or similar must be replaced.

Info Note 1: See NEMA GD 1-2019 for help with evaluating water damaged equipment.

Info Note 2: See NEMA GD 2-2021 for help with evaluating damage from fire or heat.

This section was added mainly as a way to deal with the reconditioning of wiring methods and conductors. Reconditioning those products is probably not physically possible. Instead of covering the subject dozens of times throughout Chapter 3, it was deemed a better solution to place the material here. In the 2023 NEC, 110.20 specified that reconditioned versions of all equipment could be legally installed, unless the code said otherwise. There was much debate on the whether the definition of “equipment” includes wiring methods and conductors. If wiring methods are damaged, they need to be replaced. Reconditioning them is probably not a realistic option, even if the code allowed it.

The two Informational Notes point to two NEMA guidelines, available at www.NEMA.org. As the notes clearly indicate, these papers can help a person determine if equipment needs to be replaced after it is damaged.

The material in 300.4(A) and (B) was not changed.

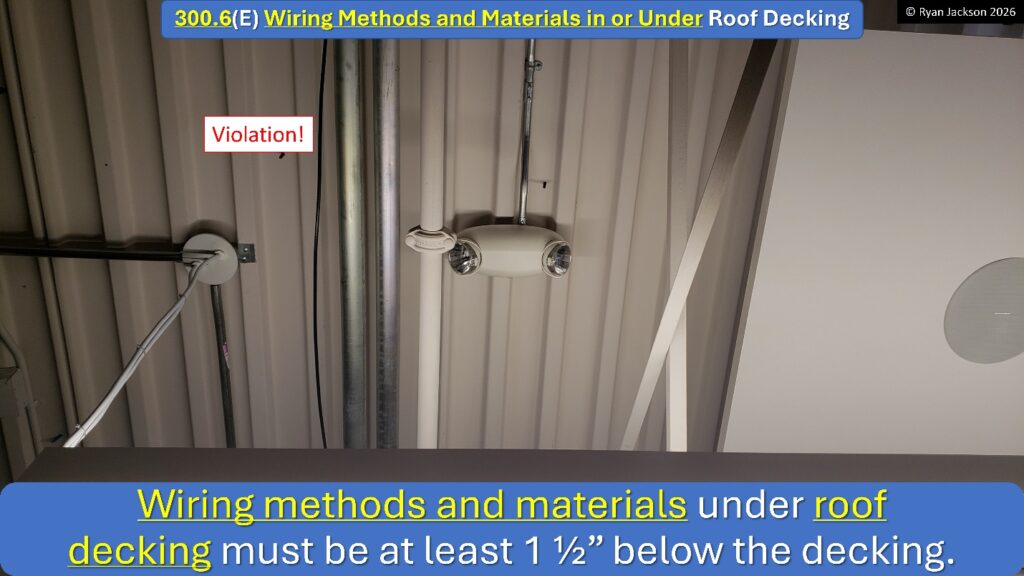

300.6 Protection Against Physical Damage.

The protection requirements for materials beneath roofs were expanded and clarified, and the protective bushing for 4 AWG and larger no longer needs to be installed before the conductors are pulled.

300.6 Protection Against Physical Damage.

(E) Wiring Methods and Materials in or Under Roof Decking. Wiring methods and materials roof decking must be kept at least 1 ½” from the lowest portion of the decking. Wiring in concealed locations of metal-corrugated sheet decking is not allowed.

Info Note: This ensures that screws used for roofing material do not damage the wiring system during the initial installation or when the roof is replaced.

Ex 1: Rigid metal conduit or intermediate metal conduit do not require this clearance if malleable iron fittings and boxes are used.

Ex 2: This requirement does not apply if the decking is beneath 2” or more of concrete.

Ex 3: Wiring methods and materials may be concealed in concrete that is at least 2” thick, and the accessibility requirements for boxes and conduit bodies in 314.29 must be followed.

(G) Fittings. Raceways with circuit conductors 4 AWG or larger must have one of the following to protect the conductor insulation:

(1) An identified fitting with a smoothly rounded insulating surface.

(2) A listed metal fitting with smoothly rounded edges.

(3) Separation from the fitting or raceway with an identified insulating material that is secured in place.

(4) Threaded hubs or bosses that are an integral part of the enclosure or raceway and provide a smoothly rounded or flared entry for conductors.

Fittings made of insulating material may be used for this requirement, but they are not allowed for mechanically securing the raceway to the enclosure.

The requirements in 300.6(E) were put in the code several years ago to address damage to equipment from the very large screws that are used to install roofing materials in commercial buildings. This section indicated that cables, raceways, and boxes needed to be at least 1 ½” from the bottom of the deck, but what about conduit bodies? Proposals to add conduit bodies were made, but instead of making the list of items longer, the Code-Making Panel decided to make it shorter but more inclusive. By stating that this rule applies to all wiring methods and materials, any previously overlooked component is now addressed and maintaining a list that covers items individually is no longer needed.

More importantly is the removal of the language in 300.6(E) regarding metal-corrugated roof decking. Other types of roofs will have nails or screws penetrating them, so why were metal-corrugated roofs the only types that had a protection requirement? Now this requirement applies to all roofs. A typical OSB roof deck for a house, for example, will have hundreds of nails that penetrate it from the shingles above. With the increasing popularity of PV arrays, the mounting screws for the module supports are likely to penetrate as well. These screws will certainly damage or destroy any electrical wiring or materials just as quickly as the screws in sheet-metal decks would.

Exception 3 to 300.6(E) was added to address roof decks that have concrete above the deck but below the roof surface. Installing a raceway inside that concrete is not particularly common, but it was inadvertently prohibited because of the language in this section. Exception 3 now allows that practice, provided the concrete is at least 2” thick and any boxes or conduit bodies comply with 314.29 for accessibility.

Section 300.6(G) was revised in the 2023 edition of the NEC to clarify that the protective bushing that section requires must be installed before pulling the conductors through the raceway. That revision made sense because the purpose of the bushing is to protect the conductors from damage when they are being pulled in, but that change also created some problems. How does an AHJ enforce it if it was not in place before the conductors were pulled? Do they have to be removed and then re-pulled, subjecting them to potential damage not once but twice? What if pulling equipment is used that protects the conductors due to the design of the equipment? It was decided that the best way to solve these issues was to delete the language added in 2023. The code seemed okay without it for 125 years and it will probably be fine without it for 125 more.

The material in 300.6(A) through (D), 300.6(F) and 300.6(H) was not changed.

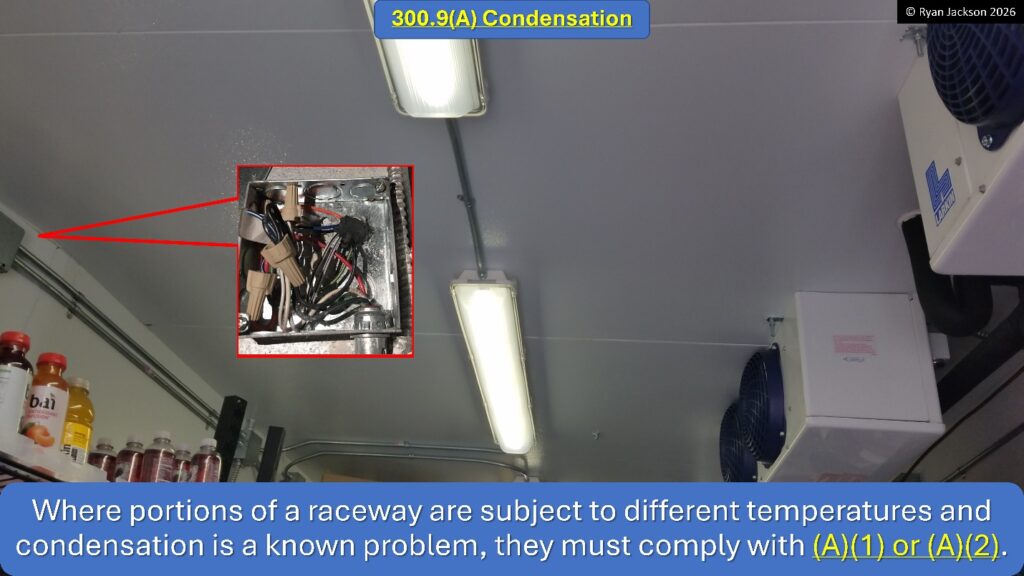

300.9 Raceways Exposed to Different Temperatures.

Another option was added for preventing condensation through raceways.

300.9 Raceways Exposed to Different Temperatures.

(A) Condensation. Where portions of a raceway or a sleeve are subject to different temperatures in areas where condensation is a known problem, the raceway must comply with one of the following:

(1) Sealants. The raceway must be sealed to prevent warm air from travelling to a colder part of the raceway and creating condensation. The sealant must be identified for use with the cable or conductor insulation, conductor material, shielding, or other components. Explosionproof seals are not required.

(2) Other Approved Ways. A listed fitting or other approved means identified for preventing the circulation of warm air and preventing condensation may be used.

Info Note: A thermal break coupling is an example of such a fitting.

For decades, the only allowable way of satisfying this requirement was to use some sort of sealant in the raceway. A new option was added to allow for a particular fitting that can also prevent condensation. The added Informational Note mentions this as well. As of this writing, such a fitting does not yet exist, but considering that a conduit manufacturer submitted the change, it is likely one will be available in the near future.

The material in 300.9(B) was not changed.

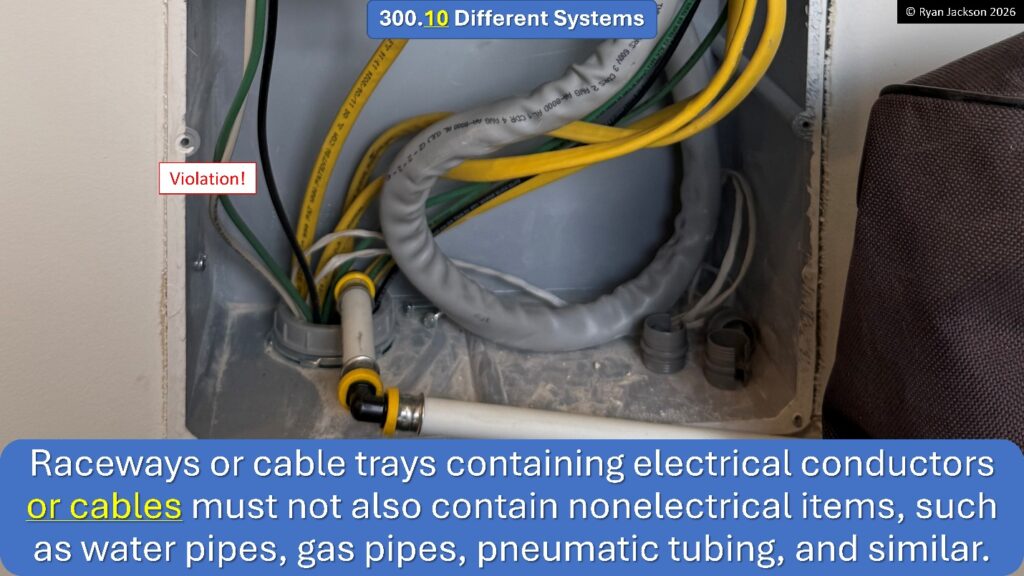

300.10 Other Systems.

Raceways and cable trays containing cables must now comply with this section.

300.10 Other Systems. Raceways or cable trays containing electrical conductors or cables must not also contain nonelectrical items, such as water pipes, gas pipes, pneumatic tubing, and similar.

Although it was likely not intentional, this section made no mention of raceways that contained cables instead of conductors. If a raceway contains THHN or XHHW or any other type of conductor, this section prohibits that raceway from also containing steam pipes, gas lines, pneumatic tubing, or any other foreign system. But what if the raceway contained a cable, such NM or SE cable? It could easily be argued that such a raceway could have contained those foreign systems, but that loophole was closed for the 2026 edition.

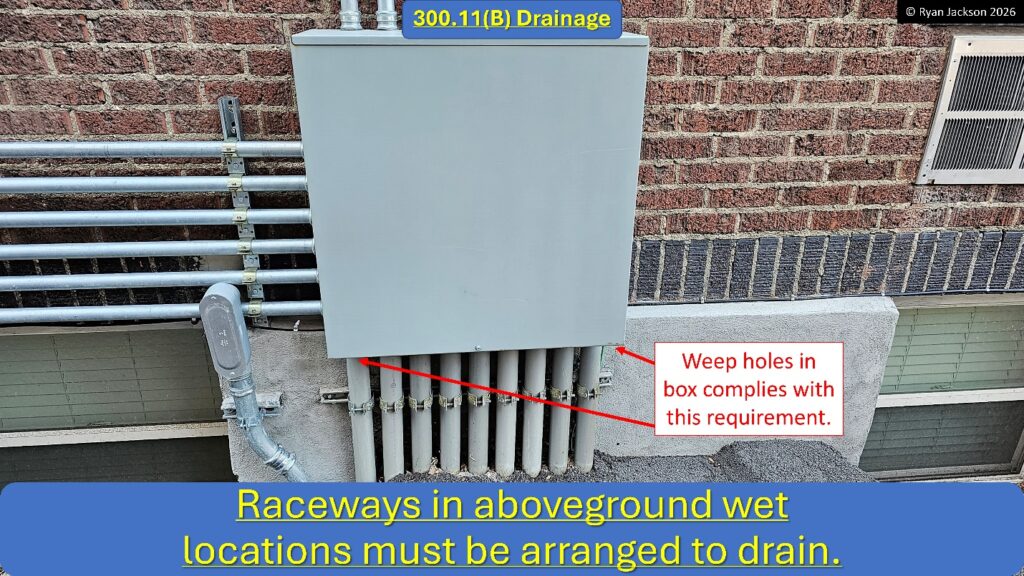

300.11 Aboveground Wet Locations.

Aboveground raceways in wet locations must now be arranged to drain.

300.11 Aboveground Wet Locations.

(A) General. The interior of a raceway installed in a wet location is considered a wet location as well, so conductors and cables within them must be listed for wet locations.

(B) Drainage. Raceways in aboveground wet locations must be arranged to drain.

This section was added a few code cycles ago to create consistency with the requirements in 225.22. That section indicates that the interior of a raceway installed in an outdoor wet location is a wet location as well, but 225.22 does not apply to indoor wet locations, so this 300.11(A) was added. Section 225.22 also requires the raceway to be arranged to drain, and 300.11 did not, despite it being created for the sake of consistency. That inconsistency was fixed in 2026. Now raceways in indoor wet locations must be arranged to drain, just like their outdoor counterparts. This can be achieved by ensuring the wet location rated enclosures they terminate to have a weep hole in the bottom of them, although there are also listed drainage fittings that can be used.

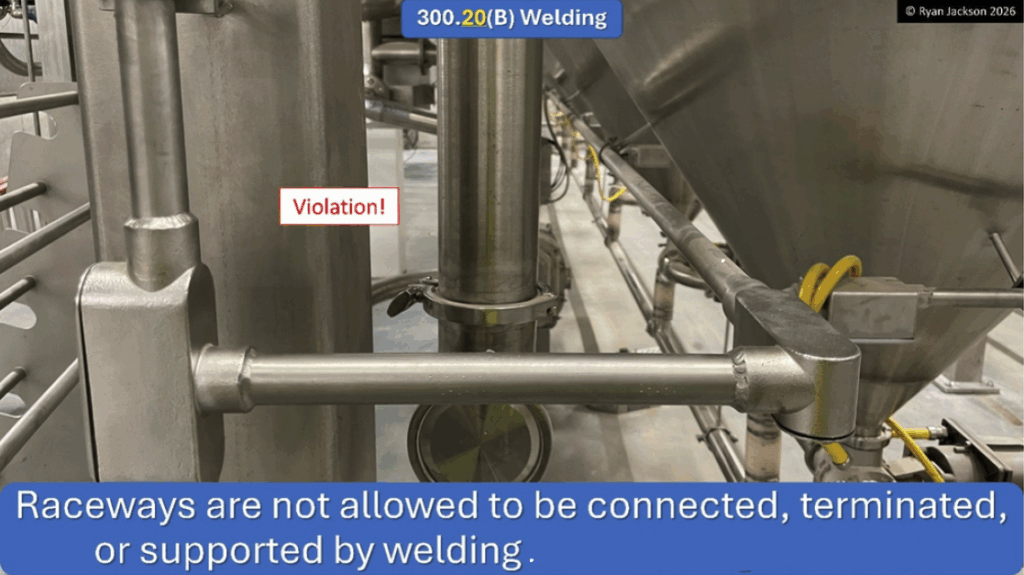

300.20 Raceway Installations.

Welding raceways is now prohibited, without exception.

300.20 Raceway Installations.

(B) Welding. Raceways are not allowed to be connected or supported by welding.

This section has long indicated that terminating, supporting, or connecting a metal raceway by welding was generally not allowed. This section allowed welding if “allowed elsewhere” in the NEC (there is no such allowance anywhere in the code) or if it was specifically designed to be welded. But which designer gets to make that determination? The designer of the product? The designer of the building? The contractor that designs the conduit installation? Note that a raceway must never be welded for multiple reasons. The quality and integrity of a weld is very difficult to verify. Any weld that is less than perfect could easily damage the contained conductors when they are installed. The raceway is also not listed to be welded. How a welded raceway would handle thousands of amperes of current during a ground fault is not known. Revisions to 300.20(B) make it very clear that raceways are not to be welded – period.

The material in 300.20(A) received an editorial revision by making one long paragraph into an itemized list without changing the technical requirements.

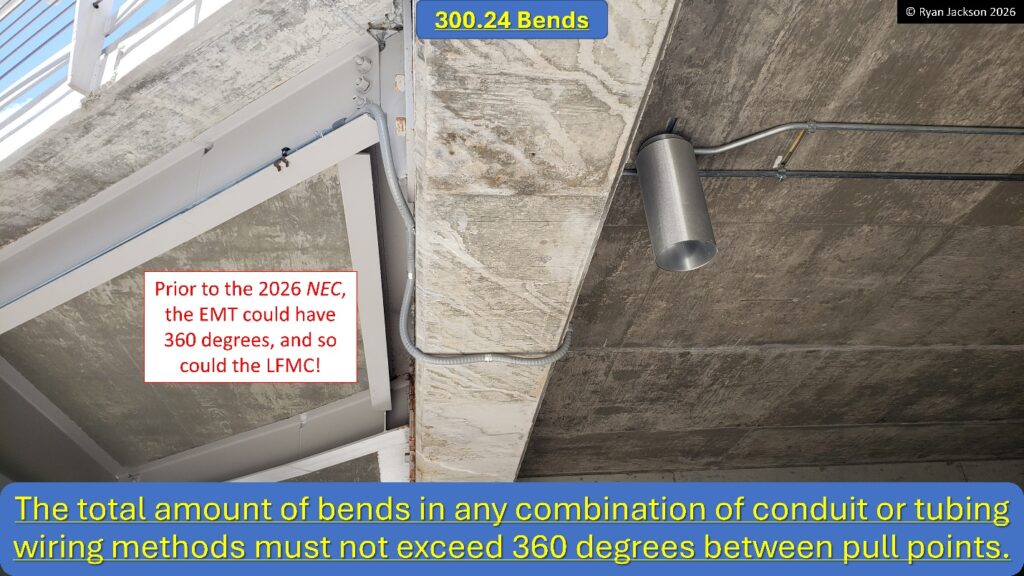

300.24 Bends.

The total number of bends in combinations of different types of raceways is now addressed.

300.24 Bends. The total number of bends in any combination of conduit or tubing wiring methods must not exceed 360 degrees between pull points.

At first glance, this section seems to tell the reader what they perhaps already knew. Limiting the number of bends to 360 degrees is a very old requirement, but the rule that states that fact is in the individual conduit or tubing article, such as 358.24 or 344.24. If taken literally, the rules allowed more than 360 degrees of bends if more than one type of wiring method was used. One could install 360 degrees of bends in a run of RMC, then use a coupling to changeover to IMC and install 360 more! This absurdity was fixed in the 2026 NEC to state what most people thought was already a requirement.

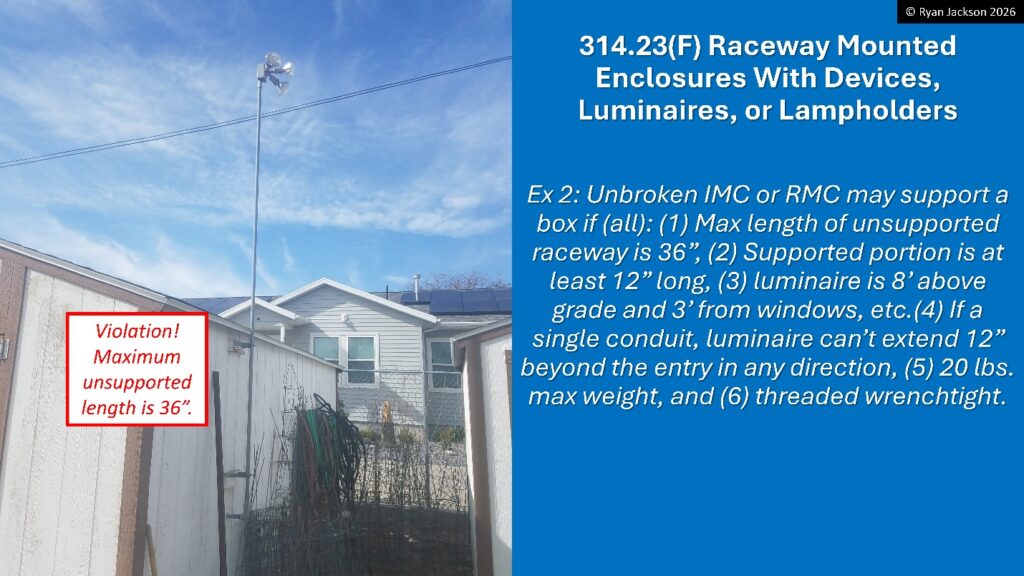

314.23 Supports for Boxes and Conduit Bodies.

The allowances for raceway supported boxes were clarified.

314.23 Supports for Boxes and Conduit Bodies.

(E) Raceway Supported Boxes Without Devices, Luminaires, or Lampholders. Enclosures up to 100 cubic inches may be supported by two or more conduits threaded wrenchtight into the box or into hubs, provided the enclosure does not contain or support wiring devices, luminaires, or lampholders. Each conduit must be secured within 36” of the enclosure, or within 18” if they enter the same side of the enclosure.

Ex: Single gang FS or FD boxes, explosionproof outlet boxes of any size, or conduit bodies not larger than the supporting raceway may be supported by the following wiring methods, even if constructed with only one raceway entry:

(1) Intermediate metal conduit (IMC)

(2) Rigid metal conduit (RMC)

(3) Rigid polyvinyl chloride conduit (PVC)

(4) Reinforced thermosetting resin conduit (RTRC)

(5) Electrical metallic tubing (EMT)

(F) Raceway Supported Boxes with Devices, Luminaires, or Lampholders. Enclosures up to 100 cubic inches containing devices, luminaires, or lampholders may be supported by two or more conduits threaded wrenchtight into the box or into hubs if the conduits are secured within 18” of the enclosure.

Ex 1: One rigid metal or intermediate metal conduit may support:

(1) a conduit body that is not larger than the raceway,

(2) a single gang FS or FD box, or

(3) a single gang explosionproof outlet box of any size.

The exception to 314.23(E) has long allowed conduit bodies to be supported by a single raceway. New to this edition, single gang FS or FD boxes and explosionproof boxes are now allowed to be supported with one raceway as well. These boxes all have conduit hubs, resulting in a strong mechanical connection to the raceway.

The exception to 314.23(F) was also changed in the same way, although with one dissimilarity. In 314.23(E)’s exception, the explosionproof box can be any size. In the exception to 314.23(F), the exception allows only single gang explosionproof boxes. It is not clear if this distinction was intentional or simply an oversight. The committee’s statement for both of these changes were identical, so it seems that a clarification may be in order for the 2029 edition.

The remainder of this section was not changed in any substantive way. Section 314.23(H) received some editorial revisions, such as making singular terms plural and creating a list out of what was a long sentence.

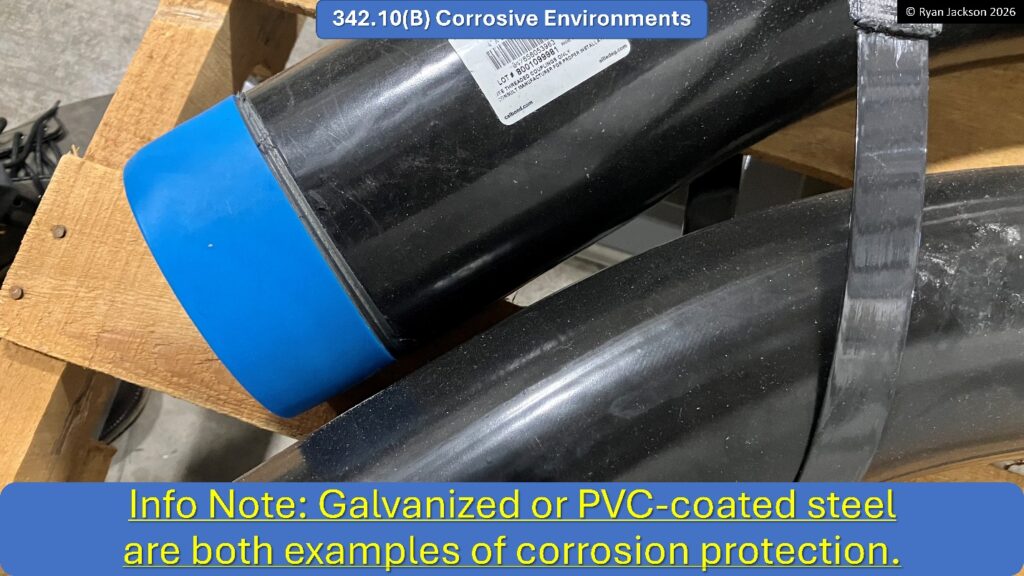

342.10 Uses Permitted.

An Informational Note was added to clarify “corrosion protection.”

342.10 Uses Permitted.

(B) Corrosive Environments. IMC, elbows, and fittings are allowed to be installed in earth, in concrete, or in areas subject to severe corrosive influences if protected by corrosion protection approved for the condition.

Info Note: Galvanized or PVC-coated steel are examples of corrosion protection.

The term “corrosion protection” is not defined in the NEC. If the reader did not realize that typical galvanized steel IMC is already inherently protected from corrosion by its zinc coating, they may think that tape or another type of supplementary protection is required. According to UL Product IQ (Guide Card DYBY for IMC, DYIX for RMC, and FJMX for EMT), RMC and IMC do not require supplementary protection, although there are instances where it could be needed for EMT.

The remainder of this section was not changed in any substantive way.

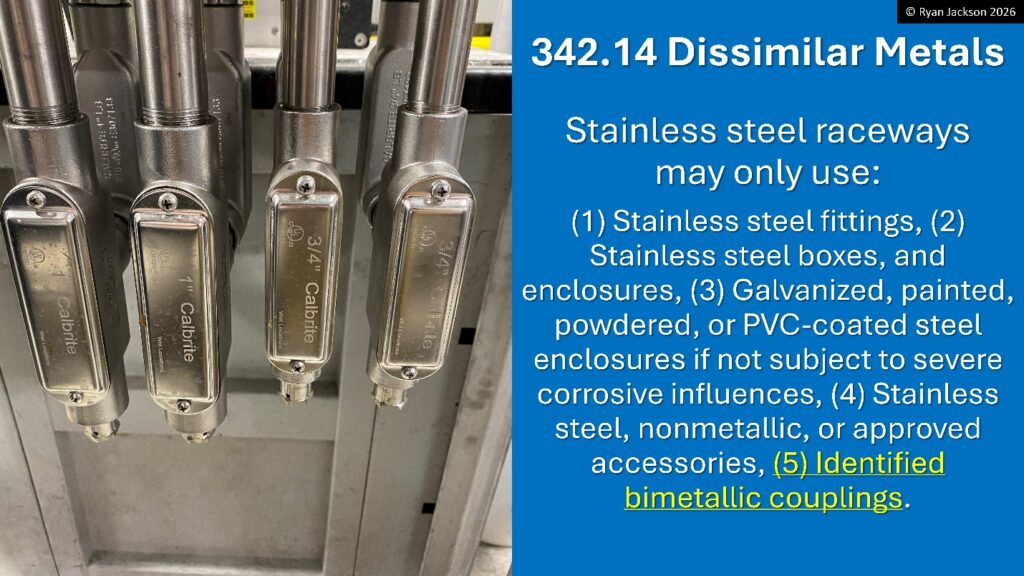

342.14 & 344.14 Dissimilar Metals.

A new option for connecting stainless steel raceways to dissimilar metal raceways was added.

342.14 (344.14) Dissimilar Metals.

Where practicable, dissimilar metal contact must be avoided. In areas not subject to severe corrosive influences, galvanized steel IMC RMC may use aluminum or stainless steel fittings. Stainless steel IMC or RMC may only be used with the following:

(1) Stainless steel fittings.

(2) Stainless steel boxes and enclosures.

(3) Galvanized, painted, powdered, or coated steel boxes and enclosures if they are not subject to corrosive influences.

(4) Stainless steel, nonmetallic, or approved accessories.

(5) Identified bimetallic couplings.

Bimetallic corrosion, also known as galvanic corrosion or galvanic action, may occur when dissimilar metals contact each other. This can be problematic when stainless steel and galvanized steel contact one another in a location where severe corrosion is likely to occur. In severely corrosive environments, stainless steel is an excellent choice due to its inherent protection. However, it is not always cost effective to install a complete system of stainless steel raceway and transitioning to galvanized steel is sometimes desirable. Although galvanic corrosion is minimal between stainless and galvanized steel in a typical location, the two metals are dissimilar and it can still happen if moisture is present. A new type of fitting is currently under development that will allow the two to be coupled together without any physical contact, therefore preventing the galvanic action. It is important to remember that all fittings must be listed and this one must be “identified,” meaning that it is suitable for this specific application.

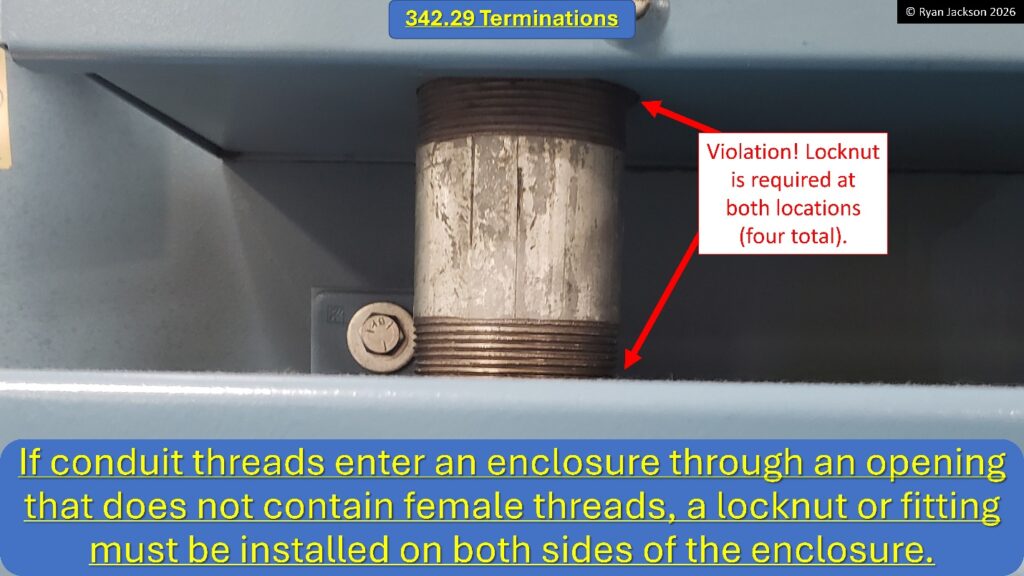

342.29 & 344.29 Terminations.

A new section was added to address conduit threads entering enclosures.

342.29 & 344.29 Terminations.

If conduit threads enter an enclosure through an opening that does not contain female threads, a locknut or fitting must be installed on both sides of the enclosure.

If a threaded conduit is installed between two enclosures that are 24” apart, how many locknuts are required? Most people would say four, meaning each enclosure has a locknut on the inside and a locknut on the outside. Some believed that only two total were required. That idea seems to contradict several code sections like 250.4 and 300.14, although the NEC did not specifically say so. Now it does. When a threaded conduit enters an enclosure, a locknut or other fitting must be installed on both sides of the enclosure. Note that this applies only when the conduit threads enter the enclosure. Threadless fittings are not addressed by this rule and neither are raceways that enter through a threaded hub. Although this section uses the word “fitting,” remember that 300.6(G) specifically indicates that a plastic or similar bushing is allowed to protect conductors but is not allowed for mechanical connection purposes, so that potential loophole is already closed.

342.42 & 344.42 Couplings and Connectors.

The requirements for couplings and connectors were editorially revised and all fittings must now be tightened.

342.42 & 344.42 Couplings and Connectors.

(A) General. All couplings and connectors must be made tight and as follows:

(1) In masonry or concrete they must be concrete-tight.

(2) In wet locations they must be listed for wet locations.

(3) When used on nonthreaded conduit ends, they must be listed for that application.

Previous versions of this section applied only to threadless fittings. It is important to know that the typical RMC or IMC “coupling” is not a coupling at all. It is not even a fitting. It is part of the conduit itself. These straight threaded “couplings” are listed to UL 6 (RMC) or UL 1242 (IMC), and not UL 514B (fittings). This means that this rule never applied to the standard coupling (that is not really a coupling) and it still does not. It only applied to threadless fittings, such as set screw or compression couplings and connectors. However, there are threaded fittings that truly are fittings. What about a three-piece fitting or a union? Those are fittings but they are not threadless fittings. What are the rules for them? There weren’t any. Now they must be made up tight, and they must be listed for wet locations or concrete-tight when needed. Most of these requirements were already found in 314.15. Although Article 314 includes “fittings” in its scope, most code users consider Article 314 the “box and enclosure” article and would never think to look there for the conduit fitting requirements.

It is worth reiterating that the standard “coupling” on the end of the conduit is not a fitting, so they do not need to be listed for wet locations when installed in one.

The language in 342.42(B) regarding running threads was not changed.

344.10 Uses Permitted.

Rigid metal conduit with PVC coating is now specifically addressed.

344.10 Uses Permitted.

(A) All Atmospheric Conditions and Occupancies.

(1) Galvanized Steel, Stainless Steel and Red Brass. Galvanized steel, stainless steel, PVC-coated steel, or red brass RMC is allowed anywhere, provided 344.10(B), (C), and (D) are followed.

Rigid metal conduit and intermediate metal conduit are both allowed in any location. You can install them in hospitals, houses, hazardous locations, and anywhere in between. The “uses permitted” sections (342.10 for IMC and 344.10 for RMC) for these raceways are substantial because unique to these conduits, there is no “uses not permitted” section. It is not quite as simple as writing “you can use it anywhere.” There are a few specific caveats. Where are aluminum raceways allowed? What about PVC-coated raceways? A PVC-coated RMC is still a steel raceway, so PVC-coated RMC can be used anywhere that galvanized RMC can be used. Although this may seem obvious to some, the code has never stated it until now.

The same change was made in 344.10(B)(1) for the same reasons. The remainder of this section was not changed in any substantive way.

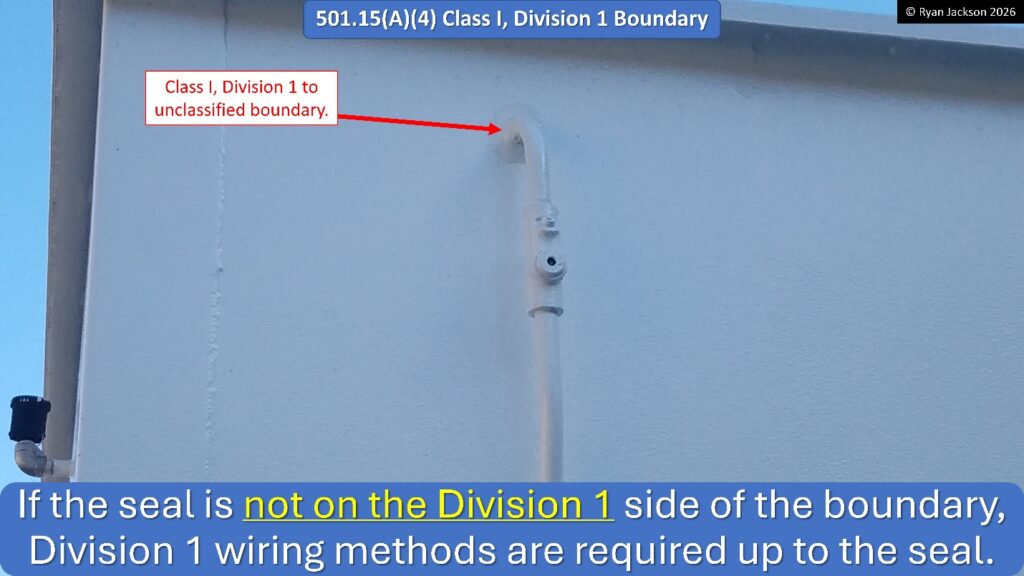

501.15 Sealing and Drainage. The requirement for sealing at a Class I, Division 1 boundary abutting an unclassified location was clarified.

501.15 Sealing and Drainage. Seals must be installed as required in (A) through (F).

(A) Class I, Division 1. In Class I, Division 1 locations, seals are required in the following locations.

(4) Class I, Division 1 Boundary. A seal is required whenever a conduit leaves a Class I, Division 1 location. The seal must be within 10’ of the Division 1 boundary, and it may be on either side of it. Boxes, enclosures, equipment, and fittings are not allowed between the boundary and the seal, other than listed explosionproof reducers.

If the seal is not on the Division 1 side of the boundary, Division 1 wiring methods are required up to the seal.

The boundary seal required in this section is intended mainly to minimize the passage of vapors and gases through a raceway and into either a Class I, Division 2 location or an unclassified location. Previous iterations of this rule gave clear guidance on the requirements for placing the Division 1 boundary seal on the Division 2 side of the boundary. A Class I, Division 1 location, however, does not always abut a Class I, Division 2 location. For example, if an entire room is a Class I, Division 1 location from the floor to a height of 18” above the floor, the space higher than 18” will often be Division 2. If one or more of the walls of that room are an exterior wall, it is common for the exterior side of the wall to be unclassified, as creating an ignitable mixture outdoors is much more difficult than creating one indoors. Given that scenario, the code is now clear on how to install the wiring that penetrates that wall, regardless of which side the seal is located. If the seal is inside, Division 1 wiring methods must be used from the seal to the unclassified location. If the seal is outdoors, Division 1 wiring methods are required outdoors until they connect to the seal itself.

The remainder of 501.15 was not changed.

517.13 Grounding and Bonding in Patient Care Spaces.

Boxes and enclosures in patient care spaces must now be metal.

517.13 Grounding and Bonding in Patient Care Spaces. Wiring for patient care spaces must comply with (A) and (B).

Ex : Luminaires that are more than 7’6” above the floor, as well as switches outside of the patient care vicinity, may be connected to the metal wiring method equipment grounding conductor discussed in (A) or the green EGC discussed in (B).

(A) Wiring Methods. All branch circuits serving patient care spaces must be in a metal raceway or cable with metal boxes, fittings, and enclosures. The metal raceway or metal cable sheath must be suitable as an equipment grounding conductor, as described in 250.118.

Perhaps this section already insinuated that the boxes and enclosures containing electrical equipment and conductors needed to be metal, but it was not clearly stated. Nonmetallic boxes can be used with metal wiring methods under certain conditions (see 250.109), but that allowance was never intended in this requirement. The rule is now clear that the entire wiring method, including the boxes and enclosures, must be metal.

The requirements in (B) pertaining to an EGC of the wire type received only minor editorial revisions.

695.7 Power Wiring.

The fire protection requirements for indoor feeder circuits were expanded.

695.7 Power Wiring.

(A) Supply Conductors.

(2) Feeders. Feeder conductors from an OCPD or an on-site generator must comply with all of the following:

(a) Routing. The conductors must remain separate from all other conductors.

(b) Associated Loads. The conductors may only supply loads associated with the fire pump system.

(c) Protection from Damage. The conductors must be protected from fire, structural failure, or operational accident.

(d) Inside Buildings. Inside of buildings, the conductors must be protected from fire for at least 2 hours by:

(1) Encasing the cable or raceway in at least 2” of concrete. The installation must provide a two-hour fire-resistance-rating as documented by a licensed professional engineer that is qualified in such designs, and documentation must be available to the AHJ;

(2) Encasing the cable or raceway in at least 5” of concrete;

(3) Using a cable or raceway that is part of a listed fire-resistive cable system; or

(4) Using a cable or raceway that is protected by a listed electrical circuit protective system.

Ex 1: Underground cables and raceways are not considered inside the building.

Ex 2: Supply conductors in the pump room or in the room where they originate do not need to comply with (d).

The use of concrete encasement for fire protection of indoor feeder circuits goes back several years, although prior to the 2017 NEC there was never a specific requirement indicating how long the concrete needed to protect the contained wiring. It was always assumed that whatever protection 2” of concrete provided was “good enough,” but a two-hour minimum requirement was added in the 2017 NEC. This put the validity of the concrete encasement into question. Does 2” of concrete encasement really provide two hours of fire protection for the conductors within? Recent testing has shown that it probably does not. An engineer that is familiar with fire-resistance ratings could document that their design provides two hours of protection with two inches of encasement based on the specific concrete mix and other applicable variables. The more likely approach, however, is that an engineer will stick to the prescriptive rule that now requires 5” of encasement as opposed to 2”.

The same change was made to 695.14(F) for fire pump control circuits, as well as Articles 700 and 708 for emergency systems and critical operations power systems, respectively.