More on Large Diameter Pipe in Building Applications

By Kim Olson, PE

Technical Consultant, Steel Tube Institute

In January, we presented an article that just scratched the surface of the discussion of alternate specifications to A500 that are applicable to large diameter round sections. The response generated a few important questions, so we decided to take a deeper dive into this topic. If you missed January’s article, you can catch up here.

The previous article spoke to API 5L as a commonly used alternative to A500 when sourcing members that exceed the capabilities of today’s A500 tube mills. Another material specification that often is brought up as a substitution request is ASTM A252.

ASTM A252

ASTM A252 is a material specification for steel pipe piles for foundations where the steel either acts as the permanent load-carrying member or as the form for cast-in-place concrete piles. STI does not recommend the substitution of ASTM A252 for ASTM A500 unless extreme care is taken. A few items of note:

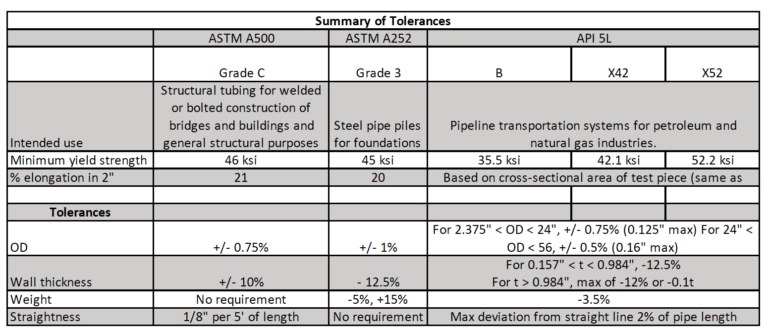

- A252 can be specified in one of three grades. Yield strengths vary from 30 to 45 ksi and tensile strengths vary from 50 to 66 ksi. All grades are produced to a lower strength than A500.

- There are no chemical composition requirements in ASTM A252. The variable chemistry may affect the members’ weldability.

- The tolerances in A252 are more lenient than A500 for wall thickness and it has no tolerance for straightness. A252 has a -12.5% wall thickness tolerance. Remember that A500 has a -10% wall tolerance, which is what the 0.93 factor in AISC 360-16 Section B4.2 is based on. If using ASTM A252, section properties should be further reduced and connection capacities checked for the thinner wall.

If you have designed in accordance with AISC 360 and A500 and a substitution request for A252 is being made, ask that the material be dual certified to ensure that the member(s) fulfill the assumptions made during design.

More on API 5L

- API 5L has two product specification levels: PSL 1 and PSL 2. PSL 1 provides a standard quality level for line pipes. PSL 2 includes additional requirements for chemical composition, fracture toughness, a maximum yield strength and additional nondestructive testing.

- In our research, we found the most commonly stocked products to be Grade B and X42 (PSL 1); however, there are 40 other grades in API 5L, so close coordination with a service center when specifying this material is a good idea.

- One of the additional requirements PSL 2 carries is a maximum on the yield-to-tensile-strengths ratio. This is of importance as some of the connection strengths given in Chapter K of AISC 360-16 are rooted in the ductility of the material, which produces the anticipated connection deformation. The yield-to-tensile-strengths ratio for the materials used in the development of AISC 360-16, Chapter K is 0.80.

AISC 360

The use of these alternative material specifications is not a slam-dunk in AISC 360. Neither API 5L nor ASTM A252 are approved materials per AISC 360-16 as specified in Section A3.1a. However, the Commentary to this section states, “Other materials may be suitable for specific applications, but the evaluation of those materials is the responsibility of the engineer specifying them.” It is the EOR’s responsibility to prove the material being used conforms to an ASTM Specification specifically listed in Section A3.

As always, we love seeing your projects and hearing about your challenges and successes. Click here to contact us or send details to hssinfo@steeltubeinstitute.org.

March 2020