HSS Splices

By Jeffrey A. Packer

Bahen/Tanenbaum Professor of Civil Engineering, University of Toronto, Ontario, Canada

Identical, or similar-sized, HSS members frequently need to be joined end-to-end, or spliced, particularly in long-span construction and in tall columns. The familiar steel construction maxim of “weld in the shop, bolt in the field”, naturally applies.

Bolted Splices

Bolts Loaded in Shear

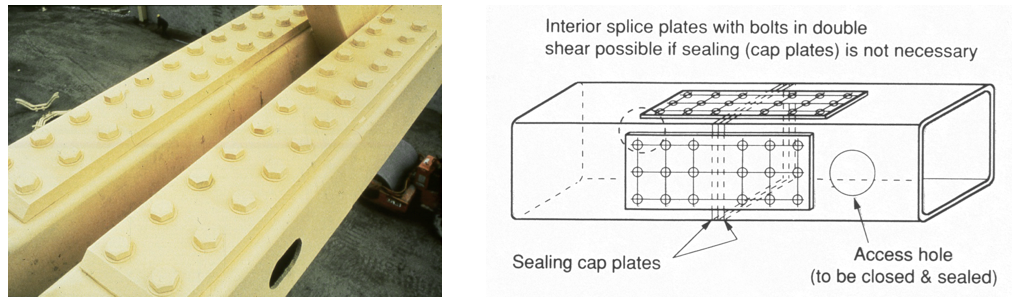

Due to the closed shape of the cross section, bolting directly into the walls of a hollow section is difficult with regular high-strength bolts. A hand (or access) hole may be necessary in order to position the nuts on the inside of the HSS (Figure 1). With splice plates just on the outside of the HSS the bolts will be in single shear, but if splice plates are used on the inside of the HSS as well the bolts will be in double shear; the number of bolts will then be halved and the connection length will be substantially less. The protruding bead of the HSS longitudinal seam weld, on the inside of the HSS, needs to be considered if using interior splice plates. Should splice plates be utilized on all four inside faces of the HSS this weld bead will interfere with one plate but can potentially be ground down by reaching into the HSS from the open end, providing the connection length is not too long. Part 7 of the AISC Manual (2011) notes that bolt sizes, regardless of the type and grade selected, of 3/4”, 7/8”, 1” and 1-1/8” are the preferred choice. Standard methods for bolted shear connections apply, using the applicable limit states in AISC 360-10 Chapter J, but one should always only design for the applied load(s) on the connection. Since bolt holes reduce the HSS net cross-sectional area the limit state of HSS net section fracture may govern over gross area yielding, thus illustrating that full HSS yield capacity is unlikely. Nevertheless, such connections are still ideal for lesser forces, which are typically present in truss web and chord members, for example.

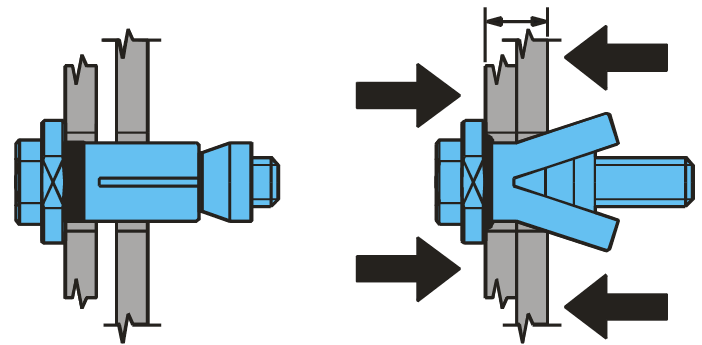

The concept of using blind bolts with HSS, in which the fastener is inserted and tightened from one side (the outside) without a nut on the inside (the blind side), has become popular and a number of fastener devices have been advocated (Packer and Henderson, 1997). The most popular, widely available and structurally viable blind fastener at present is the Lindapter Hollo-Bolt® (Figure 2). These expansion bolts have recently received structural approval for resisting certified shear and tension loads in bearing-type connections, in static and seimic loading applications, by ICC-ES (2015). The largest available nominal diameter is only 3/4” (M20) and significant clearance holes are needed in the HSS wall to accommodate the fastener (e.g. 1-5/16” hole for the 3/4″ size Hollo-Bolt), which further decreases the HSS net section fracture capacity.

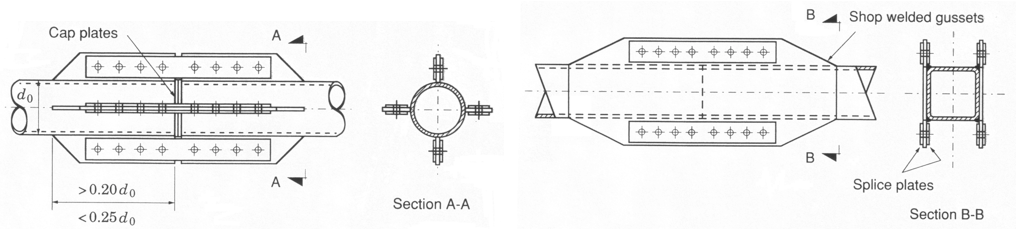

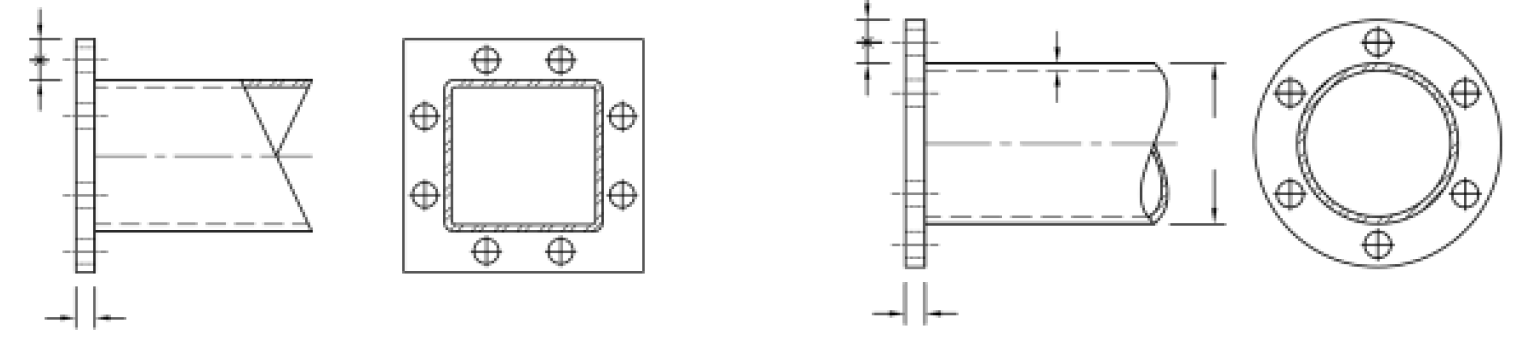

Bolting outside the HSS, for shear connections, is thus common since regular ASTM high-strength bolts can be used and the full cross-sectional area of the HSS is preserved. Some examples are illustrated in Figure 3, which also show the suitability for round HSS. Both permit sealing the HSS ends with cap plates.

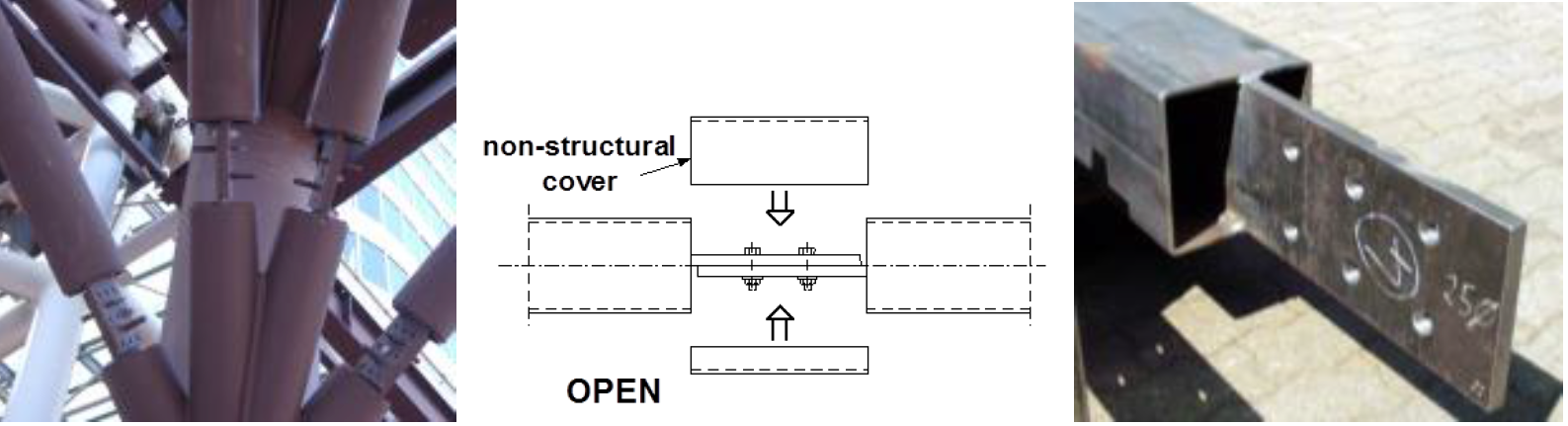

The above connections may be structurally efficient but they would generally be perceived as being unsuitable for architecturally exposed structural steel (AESS). If bolted connections need to be hidden from view, cover plates – shaped to match the HSS – can obscure the bolted shear connection (Figure 4). Site bolting can still be performed and thin cover plates lightly screwed into place after.

Bolted end-plate connections (Figure 5) are another widely used method for bolting beyond the HSS member, whether the member is in tension or compression (or in combination with bending). Design procedures (and design examples) for axially loaded tension connections, for both rectangular (bolted on two sides or on all four sides) and round HSS, are given in AISC Design Guide No. 24 (Packer et al., 2010). These design methods entail a consideration of prying action on the bolts, which should be fully pre-tensioned. One advantage of this connection type is that it allows HSS of different size to be spliced together. When bolted end-plate connections are subject to both axial load (P) and bending moment (M), a hypothetical “effective axial load” can be computed equal to P ± (M/W) A, where A is the cross-sectional area of the HSS and W is the elastic (S) or plastic (Z) section modulus of the HSS (Packer et al., 2009). The connection can then be conservatively designed on the basis of the maximum effective tension load.

Welded Splices

Welded splices, when used, generally arise in columns. Whereas the splice locations in long-span construction are relatively optional and often dictated by handling and transportation requirements, in columns the splice positions are dictated by the supplied HSS lengths, OSHA requirements and constructability. Boulanger et al. (2016) recommend that column splices be conservatively located 5 feet above the tops of floor beams. For buildings subject to seismic loading, AISC 341-10 Chapter D2.5a requires that column splices be located at least 4 feet above the finished floor level to permit installation of perimeter safety cables prior to erection of the next tier and to improve accessibility. With complete joint penetration (CJP) groove weld splices, AISC 341-10 relaxes this rule to a height above the beam-to-column flange connection of at least H (the depth of the HSS column).

For field welding, great care must be taken with regard to temporary support and splice alignment, pre-welding. Column splices within seismic force resisting systems such as Moment Resisting Frames (MRFs) have a very high demand on the welded butt joint, such that member anticipated over-capacity can be attained. CJP groove welds will be necessary in such situations, typically detailed with a root opening. For column splices in seismically loaded buildings with lower demand, and those in non-seismic construction, partial joint penetration (PJP) groove welds will often be adequate and – where fit for purpose – should be favored over CJP welds. PJP welds are typically detailed with no root gap, allowing partial bearing of the mating HSS members. Relative to CJP welds, PJP welds have a reduced welding cost, lower testing requirements and require less-specialized welders (Boulanger et al., 2016). Prequalified joint details and Welding Procedure Specifications (WPSs) are given in AWS D1.1 (2015).

References

AISC. 2010. “Specification for Structural Steel Buildings”, ANSI/AISC 360-10, American Institute of Steel Construction, Chicago, IL.

AISC. 2010. “Seismic Provisions for Structural Steel Buildings”, ANSI/AISC 341-10, American Institute of Steel Construction, Chicago, IL.

AISC. 2011. “Steel Construction Manual”, 14th edition, American Institute of Steel Construction, Chicago, IL.

AWS. 2015. “Structural Welding Code – Steel”, AWS D1.1/D1.1M, 23rd edition, American Welding Society, Miami, FL.

Boulanger, S., Drucker, C., Kruth, L.F., Miller, D.K. and Meyer Boake, T. 2016. “The Splice is Right”, Modern Steel Construction, March, pp. 48-51, and NASCC: The Steel Conference, April, Orlando, FL.

ICC. 2015. “Hollo-Bolt® 3 Part and Hollo-Bolt® 5 Part Fasteners”, ICC-ES Report ESR-3330, International Code Council Evaluation Service, Brea, CA.

Packer, J.A. and Henderson, J.E. 1997. “Hollow Structural Section Connections and Trusses – A Design Guide”, 2nd edition, Canadian Institute of Steel Construction, Toronto, ON.

Packer, J.A., Sherman, D. and Lecce, M. 2010. “Hollow Structural Section Connections”, Steel Design Guide No. 24, American Institute of Steel Construction, Chicago, IL.

Packer, J.A., Wardenier, J., Zhao, X.-L., van der Vegte, G.J. and Kurobane, Y. 2009. “Design Guide for Rectangular Hollow Section (RHS) Joints under Predominantly Static Loading”, CIDECT Design Guide No. 3, 2nd edition, Comité International pour le Développement et l’Étude de la Construction Tubulaire, Geneva, Switzerland.

July 2016