2023 National Electrical Code® (NEC®) Changes

The National Electrical Code (NEC) is used in all 50 of the United States, as well as several countries in North, Central, and South America. It is updated every three years. As always, the National Electrical Code saw many changes in the 2023 edition, and this article discusses some of the changes that address steel conduit and tubing.

ARTICLE 250 – GROUNDING AND BONDING

250.6 Objectionable Current.

The types of currents not considered objectionable were clarified.

250.6 Objectionable Current.

(C) Temporary Currents Not Considered Objectionable. Current from a ground fault is not considered objectionable current, nor is current from any connection required by this article.

For most people, seeing 10 Amperes (or more) on a grounding electrode conductor (GEC) is surprising and seems like an immediate danger; however, it is quite normal in many installations. Section 250.50 requires an underground water pipe to be connected to the grounding electrode system if it is present. In a typical neighborhood, if the underground water pipe supplying one house is copper, every other house in the neighborhood is likely to have copper too. Because the GEC is in parallel with the utility neutral, your house’s water pipe is electrically continuous to your neighbor’s. Because the water pipe is such a good grounding electrode, it will often have nearly as much (or perhaps even more) current than your service neutral conductor and will often have current flowing even if your service is disconnected. This phenomenon has been known for well over 100 years and is not considered objectionable current.

Another example of current that is not considered objectionable is the current that flows on metal raceways and equipment on the supply side of the service. The service equipment is required to be connected to the utility neutral conductor, and, ultimately, so are all other metal parts on the line side of the service. The amount of current is typically quite small, and even more importantly, the voltage on those metal parts is even lower. This installation practice has been commonplace for 150 years, and has not been shown to be hazardous, so how could it be considered objectionable?

ARTICLE 300 – GENERAL REQUIREMENTS FOR WIRING METHODS AND MATERIALS

300.4 Protection Against Physical Damage.

The rules for protecting raceways below metal-corrugated roof decking were slightly revised.

300.4 Protection Against Physical Damage. Conductors, raceways, and cables must be protected against physical damage.

(E) Cables, Raceways, or Boxes Under Metal-Corrugated Roof Decking. Cables, raceways, and enclosures in exposed or concealed locations under metal-corrugated sheet roof decking must be kept at least 1 ½” from the lowest portion of the decking. Wiring in concealed locations of such decking is not allowed.

Info Note: This ensures that screws used for roofing material do not damage the wiring system during the initial installation or when the roof is replaced.

Ex 1: Rigid metal conduit or intermediate metal conduit do not require this clearance if malleable iron fittings and boxes are used.

Ex 2: This requirement does not apply if the decking is beneath 2” or more of concrete.

The requirement to protect wiring beneath roof decks was clarified by adding exception number two. Although the existing informational note alluded to the fact, the Code did not clearly state that compliance was only needed for roof decks that are likely to receive roofing screws. A metal deck with 2” of concrete above it would not receive such a screw, so the exception removes any debate. The existing exception was also revised to require malleable iron fittings or boxes if the exception is to be used. This makes sense when considering aluminum fittings, but perhaps not as much sense when considering stainless steel fittings.

300.5 Underground Installations.

Cover requirements for EMT were added in Column 3 and the requirements for a warning ribbon were expanded.

300.5 Underground Installations.

(A) Cover Requirements. Cables and raceways installed underground must have cover as required in Table 300.5.

Installing EMT in the concrete floor slab of a commercial building is a practice as old as EMT itself. Placing EMT in direct contact with earth is far less common but not unheard of. Interestingly, Table 300.5 never allowed for either of these installations, although it was almost certainly just an oversight. Once that oversight was caught, debate ensued as to which column of the table EMT should be placed in. It is certainly not as strong as IMC or RMC, but it probably is strong enough to survive being hit with a hand shovel. Initially, the requirements for buried EMT were going to be the same as IMC and RMC, but ultimately this was changed to treat EMT like PVC or RTRC in Column 3 of the table. Table Note 6 was added to remind the Code user that 358.10 must be satisfied when installing EMT in concrete or earth. That section requires corrosion protection in certain applications depending on the soil and the material of the EMT itself.

300.17 Number of Conductors in Raceway.

Cables are now included in the raceway fill section.

300.17 Number of Conductors in Raceway. The number of conductors or cables in a raceway is limited to ensure that they can be installed without damaging their insulation.

Info Note: See the 3xx.22 section of the applicable raceway article, such as 358.22 for EMT.

Limiting the number of conductors in a raceway ensures that their insulation is not damaged during installation. Although it perhaps goes without saying, the same is true for cables. Installing a cable in a raceway is permitted, and the 3xx.22 section of the applicable raceway specifically allows the practice if the cable wiring method does not prohibit it. Currently, any cable is allowed in any raceway. Although the 3xx.22 sections require the raceway fill provisions to be satisfied when installing cables, this section did not.

310.15 Ampacity Tables.

The rooftop temperature correction requirement was slightly reduced.

310.15 Ampacity Tables.

(B) Ambient Temperature Correction.

(2) Rooftops. If raceways or cables are exposed to sunlight on or above a rooftop, the raceway or cable must be installed at least ¾” above it, or an additional 60°F must be added to the ambient temperature.

Ex: The additional 60°F is not required if the conductors are Type XHHW-2.

Since its inclusion in the 2008 NEC®, this section has received many revisions and clarifications. Requirements have been decreasing since 2017. The allowance of ignoring the increased temperature correction factor for raceways that are at least 7/8” above the rooftop allowed for strut-type supports to be used. Unfortunately, not every strut is 7/8” (some are ¾”). Revisions to this edition fix that problem.

ARTICLE 342 – INTERMEDIATE METAL CONDUIT: IMC

342.20 Sizes

Larger IMC is now allowed.

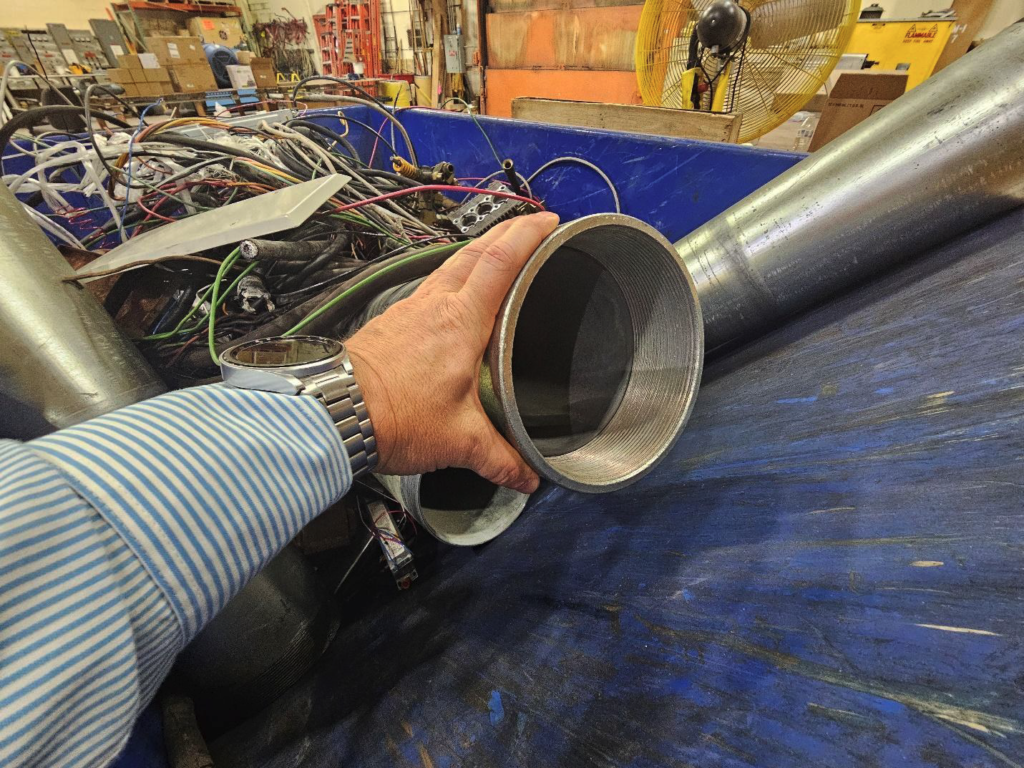

342.20 Sizes.

(A) Minimum. The smallest size IMC allowed is trade size ½.

(B) Maximum. The largest size IMC allowed is trade size 6.

Intermediate metal conduit is now allowed in trades size 5 and 6 (5” and 6”). This was already the case for rigid metal conduit and considering that the permitted applications of IMC RMC are essentially the same, there is no reason to not allow it for IMC as well. It is yet to be seen however, if such a product will be manufactured due to the relatively low demand for such a large raceway.

342.30 Securing and Supporting.

Securing raceways inside finished walls of existing buildings is no longer required. Similar changes were made to Article 344 for rigid metal conduit.

342.30 Securing and Supporting.

(A) Securing. IMC must be secured:

(1) Within 3’ of every conduit termination, such as a box, conduit body, cabinet, or similar.

(2) Within 5’ of the conduit termination if structural members are spaced such that securing within 3’ is not practicable.

(3) At overhead masts, securing is not required within 3’.

Ex: In existing or prefinished walls, unbroken lengths need not be secured.

Section 358.30(A) has an exception allowing unsecured raceways in existing walls and prefinished walls, yet Articles 342 and 344 contain no such allowance. These changes remove that oversight.

ARTICLE 358 – ELECTRICAL METALLIC TUBING: EMT

358.10 Uses Permitted.

Fittings for directly buried EMT are now addressed, as are manufactured wiring systems.

358.10 Uses Permitted.

(A) Exposed and Concealed. EMT may be exposed or concealed in:

(1) Concrete, earth if fittings identified for direct burial are used, or where subject to severe corrosive influences if protected in accordance with 358.10(B).

(2) Dry, damp, or wet locations.

(3) Hazardous locations where specifically allowed in Chapter 5.

(4) Manufactured wiring systems [604.100(A)(2)].

If allowed by Section 300.6, EMT can be directly buried. According to the UL Guide Card (FJMX), EMT in contact with earth requires supplementary corrosion protection, so it is not often the first choice for underground raceways. It can be buried if the correct fittings are used, but if one desires the physical protection that only steel conduit can provide, RMC or IMC is typically the better solution.

Manufactured wiring systems are usually constructed of MC or AC cable or flexible metal or liquid-tight flexible metal conduit. Section 604.100(A)(2) also recognizes EMT as an allowable option, so this section was revised to correlate with Article 604.

358.20 Sizes.

The maximum allowable size for EMT was increased.

358.20 Sizes.

(A) Minimum. The smallest size EMT allowed is trade size ½.

(B) Maximum. The largest size EMT allowed is trade size 6.

The maximum size for rigid metal conduit is trade size 6, and revisions to the 2023 NEC® allow for trade size 6 intermediate conduit as well. In installations where a raceway larger than trade size 4 is needed, there is now a lighter weight option in EMT.

ARTICLE 501 – CLASS I LOCATIONS

501.10 Wiring Methods.

Coated RMC and IMC are now specifically addressed.

501.10 Wiring Methods. Only the following wiring methods are allowed in Class I locations.

(A) Class I, Division 1.

(1) General.

(1) Threaded rigid metal or threaded intermediate metal conduit, including those coated with supplemental corrosion protection.

Coated IMC and RMC have been used for decades but were not specifically mentioned in this section. Although they were not mentioned, they are still RMC and IMC, so they were still allowed. This change, along with several other similar ones in this section, should be viewed as editorial only. Although the changes are not technical, they could help the code user understand the requirement and potentially prevent conflict between designers, installers, and enforcers.

ARTICLE 501 – CLASS II LOCATIONS

502.10 Wiring Methods.

Coated RMC and IMC are now specifically addressed, and EMT fittings must be of the compression type.

502.10 Wiring Methods. Only the following wiring methods are allowed in Class II locations.

(A) Class II, Division 1.

(1) General.

(1) Threaded rigid metal or threaded intermediate metal conduit, including those coated with supplemental corrosion protection.

(B) Class II, Division 2.

(1) General.

(3) Dusttight wireways or EMT with compression-type fittings.

Although coated RMC and IMC were already allowed, they were not specifically addressed. Their inclusion could help to remove potential disagreements in the field and are a welcome sight. Unlike Class I locations, EMT is allowed in Class II, Division 2 locations. In order to ensure that the raceway remain as dusttight as possible, set-screw fittings are no longer allowed for EMT.

ARTICLE 604 – MANUFACTURED WIRING SYSTEMS

604.100 Construction.

New options for raceway types were added.

604.100 Construction.

(A) Cables and Raceways.

(1) Cables. Cables must be listed and constructed of AC or MC cable with 12 AWG, 10 AWG, or 8 AWG conductors.

(2) Raceways. Flexible metal conduit, liquid-tight flexible metal conduit, liquid-tight flexible nonmetallic conduit, or EMT with 600V rated conductors, size 12 AWG through 8 AWG may be used. A copper equipment grounding conductor that is the same size as the ungrounded conductors must be included.

Considering that EMT is a more robust wiring method than the other products recognized in this article, there is no reason to not allow it. Manufactured wiring systems are most commonly used for lighting applications in big box retail and office environments, although outside of the box thinking could find a niche for a nonflexible option like EMT.