Seismic Applications of HSS in Moment Resisting Frames

By Emily Guglielmo, SE

Martin/Martin, STI Technical Committee Member

Use of Hollow Structural Section (HSS) members in moment-frames to resist seismic forces has numerous potential advantages. HSS shapes provide effective bi-axial column strength, while having minimal impact on architectural layout. Furthermore, HSS shapes are particularly efficient and economical under compression loads. Finally, HSS column shapes offer internal fireproofing options, attributes unavailable with comparable wide flange shapes.

As mentioned above, HSS sections are commonly desired in steel frames in which members experience loading in multiple directions. Square and circular HSS have very efficient shapes for multi-axis loading due to their uniform geometry along each cross-sectional axis, resulting in uniform strength characteristics.

In addition to having superior multi-axis properties, HSS sections are inherently more efficient compression members than other structural steel sections, including wide flanges. The reason for this efficiency is their geometric shape. The radius of gyration (rx, ry), particularly about the minor axis, is significantly greater than that of an open section of a similar size, area, and weight. This robust radius of gyration results in a much lower slenderness ratio for the same effective length, resulting in a greater compression capacity.

Per AISC 341 Chapter E, a seismic force-resisting system utilizing moment-resisting frames with HSS columns and either wide flange or HSS beams, can be designed as an Ordinary Moment Frame (OMF). Classification as an OMF requires simple calculations and minimal supplemental attention to the connection details, reinforcement, and sizing. However, if a moment frame is to be classified as an Intermediate Moment Frame (IMF) or a Special Moment Frame (SMF), there are two options currently available to demonstrate acceptable beam-column connections. The designer must either employ a “pre-qualified connection”, as approved by AISC 358-10, or meet a “conformance demonstration” through specific laboratory testing.

While numerous public domain connections for moment-resisting frames under high seismic loading are available as prequalified designs in AISC 358, none directly pertain to HSS members. This absence of AISC-endorsed, generic seismic moment connections is a substantial barrier to using HSS columns in such frames in North America.

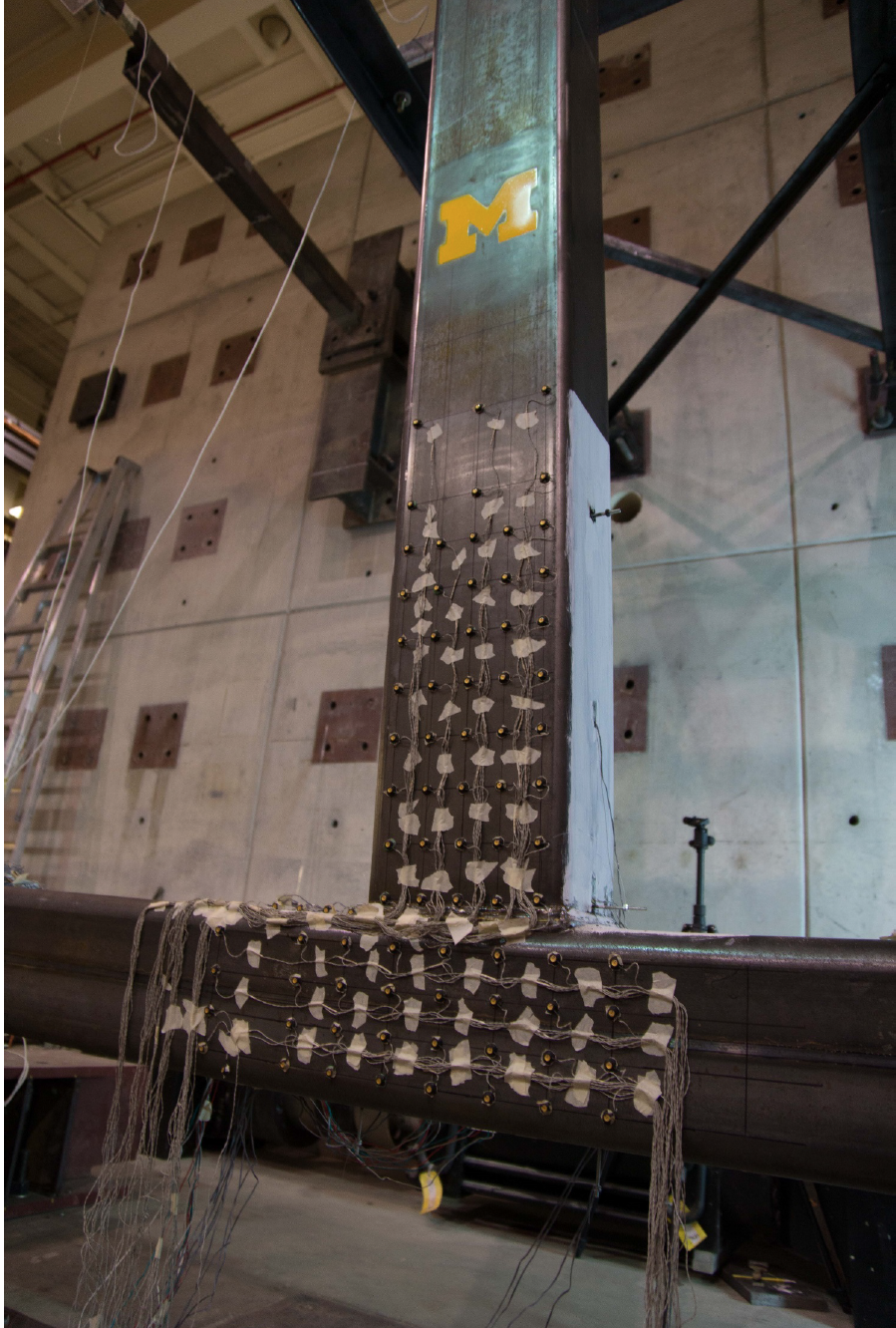

A comparison of HSS use in the United States to our seismically active Japanese counterparts reveals limited use in the United States, but significant (greater than 90% of steel buildings) usage in Japan (Kurobane 2002). Research is ongoing toward the pre-qualification of HSS moment frames into daily practice in the United States. One particular study “Seismic Applications of Hollow Structural Sections in Moment Resisting Frames” is led by Dr. Jason McCormick at the University of Michigan and funded by AISC. This research focuses on developing innovative connection methods for HSS members in high seismic structures. Specifically, the study involves a detailed study of the behavior of HSS members, development of connection details for various HSS moment connections, and testing of the most promising connection configurations for use in both IMF and SMF systems. See photos of testing of HSS moment frames.

However, until this research and pre-qualification process is complete, connections not prequalified by AISC 358 must be tested in accordance with Appendix S of AISC 341. In the case of HSS column (or beam) moment frame applications, the beam-column joint should be tested per guidelines, mimicking the actual proposed configuration.

Worth noting, AISC 358 does permit a prequalified proprietary product which allows for the utilization of HSS shapes as moment frame columns. The ConXtech ConXL moment connection for Special Moment Frames (SMFs) and Intermediate Moment Frames (IMFs) is permitted with specific beam clear span-to-depth ratios and 16” square columns. This proprietary connection utilizes collar assemblies around a square HSS column by fastening with high-strength pre-tensioned bolts. As practicing engineers are aware, current practice generally minimizes the number of moment-resisting frames in a building to reduce cost. One major benefit of the ConXtech framing system is that a redundant, well-distributed moment-resisting space frame is achieved as nearly all beam-column connections are moment-resisting. This increased number of frames results in greater robustness, a more well-distributed seismic-resisting system, and increased resistance to progressive collapse.

In summary, numerous reasons exist why HSS shapes may be beneficial for use in moment-frame applications, ranging from efficiency to aesthetics. However, current codes preclude common usage of these shapes. While there are several work-around options, including testing and proprietary connections, greater usage of HSS shapes in moment frame applications requires careful consideration and further investigation.

References:

Kurobane, Y. (2002). Connections in tubular structures. Progress in Structural Engineering. 4, 35-45.

McCormick, Jason. Seismic Applications of Hollow Structural Sections in Moment Resisting Frames, 2010 – 2014

April 2014