Selecting the Right Round HSS

By Kimberley Olson, PE

Technical Consultant, Steel Tube Institute

In a previous eNews article titled “A500 Versus A53: Different From the Inside Out“, the material and tolerance differences between these materials were pointed out. What wasn’t discussed are the numerous choices one has when it comes to available sizes.

I have fielded a number of questions recently pertaining to the availability of round HSS shapes. Rounds, much like their rectangular (and square) counterparts, come in many outside dimension and wall thickness combinations. It’s unreasonable to expect that every service center will stock all of these different combinations. The Steel Tube Institute maintains a Capability Tool that can help designers discern what sections are most available based on the number of producers making that section. Additionally, this article will help designers when it comes to specifying a round hollow structural section member.

When first published by ASTM, the A500 specification only included “shapes”, meaning rectangles and squares exclusively. In the structural market, we would specify ASTM A53 for round shapes. When rounds were added to A500 and producers started making them, they would make standard pipe sizes, as many of them were A53 producers as well. Fast forward to present day. A500 includes round and rectangular sections and should be specified for structural applications (see above referenced article). Additionally, the most frequently produced round sections still correspond to standard pipe sizing.

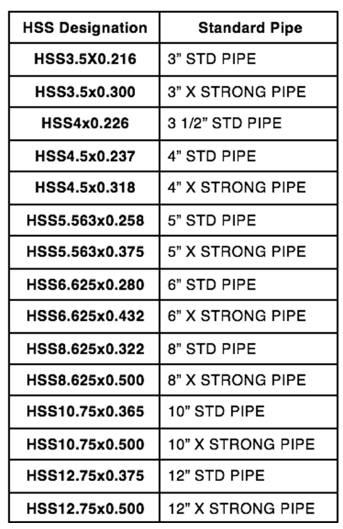

I think the point I’m trying to make is best explained in the chart to the left. Hopefully you bookmark it, print it and stick it on your wall, or highlight these sizes in your design reference of choice. The A500 sections listed should be widely available in the marketplace and a safe bet to specify on drawings.

By no means should you limit your designations to these sections. If another section is required, I recommend checking the Capability Tool to make sure the necessary section is produced domestically, as can be done for rectangular sections also.

November 2016